1. Introduction

Understanding the deformation and breakup of a droplet in a viscous flow plays an essential role in designing stable emulsions and foams for diverse industrial applications (Langevin Reference Langevin2000; Dan et al. Reference Dan, Gochev, Krägel, Aksenenko, Fainerman and Miller2013; van Kempen et al. Reference van Kempen, Schols, van der Linden and Sagis2013; Lam, Velikov & Velev Reference Lam, Velikov and Velev2014; Hamed, Schenck & Fiegel Reference Hamed, Schenck and Fiegel2020). Droplet breakup analysis can guide the generation of dispersed-phase droplets with a size distribution aptly tuned for chemical reactors, droplet microencapsulation, inkjet printing and spraying systems (Frankel & Acrivos Reference Frankel and Acrivos1970; Kennedy, Pozrikidis & Skalak Reference Kennedy, Pozrikidis and Skalak1994; Belyaeva et al. Reference Belyaeva, Della Valle, Neufeld and Poncelet2004; Lemenand et al. Reference Lemenand, Dupont, Della Valle and Peerhossaini2013; Daly et al. Reference Daly, Harrington, Martin and Hutchings2015; Narsimhan, Wang & Xiang Reference Narsimhan, Wang and Xiang2019; He et al. Reference He, Yang, Qin, Wen and Zhang2017). There is extensive research on the deformation and breakup of a clean droplet under different domains of external flow types. Barthes-Biesel & Acrivos (Reference Barthes-Biesel and Acrivos1973) first developed perturbation theories for examining the critical conditions for the breakup of a droplet under a general linear flow field in the limit of small droplet deformations. Some theoretical studies have examined the deformation and breakup of long slender droplets in shear and extensional flows where the internal fluid has a very low viscosity compared with the suspending fluid (Acrivos & Lo Reference Acrivos and Lo1978; Hinch & Acrivos Reference Hinch and Acrivos1979, Reference Hinch and Acrivos1980). Some studies have experimentally investigated the transient effects in the deformation and burst of viscous droplets (Bentley & Leal Reference Bentley and Leal1986; Stone, Bentley & Leal Reference Stone, Bentley and Leal1986). Rallison & Acrivos (Reference Rallison and Acrivos1978) and Rallison (Reference Rallison1981) have numerically explored the deformation and breakup of a viscous droplet in extensional and shear flows.

The role of simple surfactants in the deformation and breakup of droplets has also been widely investigated. Here, the role of surfactants is to change the surface tension of the interface as well as introduce Marangoni flows (Stone & Leal Reference Stone and Leal1990; Milliken, Stone & Leal Reference Milliken, Stone and Leal1993; Pawar & Stebe Reference Pawar and Stebe1996; Li & Pozrikidis Reference Li and Pozrikidis1997; Vlahovska, Bławzdziewicz & Loewenberg Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Kamat et al. Reference Kamat, Wagoner, Thete and Basaran2018). Some studies have also focused on the deformation and burst of elastic capsules in extensional and simple shear flows using theories and experiments (Li, Barthes-Biesel & Helmy Reference Li, Barthes-Biesel and Helmy1988; Chang & Olbricht Reference Chang and Olbricht1993). The mechanical behaviour of artificial capsules and vesicles and their different modelling strategies are reviewed in Barthès-Biesel (Reference Barthès-Biesel2009).

Suspensions of droplets and bubbles laden with lipid bilayers, polymers, proteins and solid particles exhibit complex interfacial rheology. The interplay among surface viscoelastic effects, Marangoni stresses, surface pressure changes, surfactant solubility and diffusivity governs the mechanics of these complex interfaces (Jaensson, Anderson & Vermant Reference Jaensson, Anderson and Vermant2021; Pourali et al. Reference Pourali, Kröger, Vermant, Anderson and Jaensson2021). The role of interfacial rheology in droplet mechanics remains underexplored. Droplet interfaces embedded with certain low-molecular-weight surfactants (eicosanol, hexadecanol) and proteins (![]() $\beta$-casein) form highly viscous membranes (Brooks et al. Reference Brooks, Fuller, Frank and Robertson1999; Fuller & Vermant Reference Fuller and Vermant2012; Gunning et al. Reference Gunning, Kirby, Wilde, Penfold, Woodward and Morris2013; Verwijlen, Moldenaers & Vermant Reference Verwijlen, Moldenaers and Vermant2013). In such systems, the in-plane friction that arises when the molecules/particles within the interface slide past each other results in viscous dissipation, i.e. interfacial viscosities. The surface rheology of viscous interfaces can be modelled using the Boussinesq–Scriven law that provides an expression for the interfacial traction that arises from the surface shear and dilational viscosities (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960). Erni (Reference Erni2011) reviews the influence of interfacial viscosity in the shear and dilational modes of deformation in systems with complex interfaces. Several experimental studies have also explored the different techniques to measure the interfacial shear and dilational rheological properties of complex fluid interfaces (Miller et al. Reference Miller, Ferri, Javadi, Krägel, Mucic and Wüstneck2010; Choi et al. Reference Choi, Steltenkamp, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Balemans, Hulsen & Anderson Reference Balemans, Hulsen and Anderson2016; Jaensson et al. Reference Jaensson, Anderson and Vermant2021).

$\beta$-casein) form highly viscous membranes (Brooks et al. Reference Brooks, Fuller, Frank and Robertson1999; Fuller & Vermant Reference Fuller and Vermant2012; Gunning et al. Reference Gunning, Kirby, Wilde, Penfold, Woodward and Morris2013; Verwijlen, Moldenaers & Vermant Reference Verwijlen, Moldenaers and Vermant2013). In such systems, the in-plane friction that arises when the molecules/particles within the interface slide past each other results in viscous dissipation, i.e. interfacial viscosities. The surface rheology of viscous interfaces can be modelled using the Boussinesq–Scriven law that provides an expression for the interfacial traction that arises from the surface shear and dilational viscosities (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960). Erni (Reference Erni2011) reviews the influence of interfacial viscosity in the shear and dilational modes of deformation in systems with complex interfaces. Several experimental studies have also explored the different techniques to measure the interfacial shear and dilational rheological properties of complex fluid interfaces (Miller et al. Reference Miller, Ferri, Javadi, Krägel, Mucic and Wüstneck2010; Choi et al. Reference Choi, Steltenkamp, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Balemans, Hulsen & Anderson Reference Balemans, Hulsen and Anderson2016; Jaensson et al. Reference Jaensson, Anderson and Vermant2021).

In recent years there have been advances in understanding the effect of surface rheology on droplet deformation and breakup using theories and numerical simulations. Flumerfelt (Reference Flumerfelt1980) first examined the impact of surface viscosities on droplet deformation in shear and extensional flows by extending the first-order perturbation analysis developed in Cox (Reference Cox1969) for a clean droplet. Narsimhan (Reference Narsimhan2019) developed second-order perturbation theories to describe the shape and rheology of a droplet with interfacial shear and dilational viscosity. The condition for the breakup of a droplet with surface viscosity in a linear flow field is presented in Singh & Narsimhan (Reference Singh and Narsimhan2020) in the limit of small droplet deformation. The deformation and breakup of a droplet in shear flow using boundary-element simulations have been explored in Gounley et al. (Reference Gounley, Boedec, Jaeger and Leonetti2016) and Luo, Shang & Bai (Reference Luo, Shang and Bai2019). Herrada et al. (Reference Herrada, Ponce-Torres, Rubio, Eggers and Montanero2022) also examined the steady-state solutions and stability of a gaseous droplet with interfacial viscosity using linear stability analysis and numerical computations in extensional flow. These previous studies have shown that the surface shear viscosity reduces the droplet deformation and increases the critical capillary number for droplet breakup compared with a clean droplet at the same viscosity ratio. In contrast, surface dilational viscosity enhances the droplet deformation and reduces the critical capillary number for droplet breakup compared with a clean droplet at the same viscosity ratio. In this work, we perform boundary-element simulations to investigate the role of surface viscosity in droplet deformation and breakup under axisymmetric extensional flow for a wide range of viscosity ratio values, interfacial viscosity and surfactant parameters. We present the mechanism behind the effect of surface shear and dilational viscosity on droplet deformation using traction arguments from interfacial viscosities. We also explore the combined impact of surface viscosity and surfactant transport on droplet relaxation in a quiescent fluid for different viscosity contrasts between the inner and outer fluid and surfactant transport parameters. We compare the results from our numerical simulations with those of second-order analytical theories in the limit of small capillary number (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020). Numerical investigation of this problem allows us to examine stronger deformations, the effects of Marangoni stresses and the effects of pressure-thickening/thinning surface viscosities, the latter of which have not been addressed in previous studies.

2. Problem set-up and methodology

2.1. Problem overview

We numerically investigate how interfacial rheology alters the dynamics of a droplet suspended in an unbounded immiscible fluid and subject to an external flow. Figure 1 shows a schematic of the problem. We consider an initially spherical droplet of radius ![]() $R^{\prime }$ placed in a uniaxial extensional flow symmetric about the

$R^{\prime }$ placed in a uniaxial extensional flow symmetric about the ![]() $z^{\prime }$ axis. We model the problem in polar-cylindrical coordinates with origin at the centre of the droplet. The internal fluid viscosity is

$z^{\prime }$ axis. We model the problem in polar-cylindrical coordinates with origin at the centre of the droplet. The internal fluid viscosity is ![]() $\lambda \eta ^{\prime }$, and the external fluid viscosity is

$\lambda \eta ^{\prime }$, and the external fluid viscosity is ![]() $\eta ^{\prime }$. The interface of the droplet has an insoluble monolayer of a surface-active agent. We assume that the surfactant monolayer is primarily viscous. In this work, we neglect surface elasticity effects and employ the Boussinesq–Scriven constitutive relationship to describe the rheology of the viscous Newtonian interface (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960). The surfactant interface has a surface shear viscosity

$\eta ^{\prime }$. The interface of the droplet has an insoluble monolayer of a surface-active agent. We assume that the surfactant monolayer is primarily viscous. In this work, we neglect surface elasticity effects and employ the Boussinesq–Scriven constitutive relationship to describe the rheology of the viscous Newtonian interface (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960). The surfactant interface has a surface shear viscosity ![]() $\eta _\mu ^{\prime }$, a surface dilational viscosity

$\eta _\mu ^{\prime }$, a surface dilational viscosity ![]() $\eta _\kappa ^{\prime }$ and a surface tension

$\eta _\kappa ^{\prime }$ and a surface tension ![]() $\sigma ^{\prime }$. As the droplet deforms under external flow, the flow around the droplet can affect the local surface tension

$\sigma ^{\prime }$. As the droplet deforms under external flow, the flow around the droplet can affect the local surface tension ![]() $\sigma ^{\prime }$, surfactant concentration

$\sigma ^{\prime }$, surfactant concentration ![]() $\varGamma ^{\prime }$ and surface viscosity (

$\varGamma ^{\prime }$ and surface viscosity (![]() $\eta _\kappa ^{\prime }$ and

$\eta _\kappa ^{\prime }$ and ![]() $\eta _\mu ^{\prime }$) on the interface. We discuss the formulations of variable surface tension and surface viscosity in the next subsection.

$\eta _\mu ^{\prime }$) on the interface. We discuss the formulations of variable surface tension and surface viscosity in the next subsection.

Figure 1. Problem overview.

The steady-state deformation of the droplet under flow is characterized by the Taylor deformation parameter ![]() $D_{Taylor}=(L^{\prime }-B^{\prime })/(L^{\prime }+B^{\prime })$, where

$D_{Taylor}=(L^{\prime }-B^{\prime })/(L^{\prime }+B^{\prime })$, where ![]() $L^{\prime }$ and

$L^{\prime }$ and ![]() $B^{\prime }$ are the lengths of the major and minor axes, respectively, as shown in figure 1. The undisturbed far-field velocity vector

$B^{\prime }$ are the lengths of the major and minor axes, respectively, as shown in figure 1. The undisturbed far-field velocity vector ![]() $\boldsymbol {u}_{\boldsymbol {\infty }}^{\boldsymbol {\prime }}$ in dimensional form is expressed as

$\boldsymbol {u}_{\boldsymbol {\infty }}^{\boldsymbol {\prime }}$ in dimensional form is expressed as

\begin{equation}

\boldsymbol{u}_{\boldsymbol{\infty}}^{\boldsymbol{\prime}}

= G^{\prime} \boldsymbol{\cdot} \begin{bmatrix} -1 & 0 &

0\\0 & -1 & 0\\0 & 0 & 2\end{bmatrix} \boldsymbol{\cdot}

\boldsymbol{x}^{\boldsymbol{\prime}}.

\end{equation}

\begin{equation}

\boldsymbol{u}_{\boldsymbol{\infty}}^{\boldsymbol{\prime}}

= G^{\prime} \boldsymbol{\cdot} \begin{bmatrix} -1 & 0 &

0\\0 & -1 & 0\\0 & 0 & 2\end{bmatrix} \boldsymbol{\cdot}

\boldsymbol{x}^{\boldsymbol{\prime}}.

\end{equation}

In the above equation, ![]() $G^{\prime }$ represents the external strain rate and

$G^{\prime }$ represents the external strain rate and ![]() $\boldsymbol {x}^{\boldsymbol {\prime }}$ represents the position vector. Throughout the paper, primed variables are in dimensional form while unprimed variables are in dimensionless form.

$\boldsymbol {x}^{\boldsymbol {\prime }}$ represents the position vector. Throughout the paper, primed variables are in dimensional form while unprimed variables are in dimensionless form.

2.2. Governing equations

We non-dimensionalize all lengths by radius ![]() $R^{\prime }$ of the initial spherical droplet, viscosities by the outer fluid viscosity

$R^{\prime }$ of the initial spherical droplet, viscosities by the outer fluid viscosity ![]() $\eta ^{\prime }$, times by the inverse strain rate

$\eta ^{\prime }$, times by the inverse strain rate ![]() ${G^{\prime }}^{-1}$, velocities by

${G^{\prime }}^{-1}$, velocities by ![]() $G^{\prime } R^{\prime }$, bulk stresses by

$G^{\prime } R^{\prime }$, bulk stresses by ![]() $\eta ^{\prime } G^{\prime }$ and surface stresses by

$\eta ^{\prime } G^{\prime }$ and surface stresses by ![]() $R^{\prime } \eta ^{\prime } G^{\prime }$. The interfacial surfactant concentration and surface tension are normalized by their initial equilibrium values

$R^{\prime } \eta ^{\prime } G^{\prime }$. The interfacial surfactant concentration and surface tension are normalized by their initial equilibrium values ![]() $\varGamma _{eq}^{\prime }$ and

$\varGamma _{eq}^{\prime }$ and ![]() $\sigma _{eq}^{\prime }$ at time

$\sigma _{eq}^{\prime }$ at time ![]() $t=0$.

$t=0$.

The fluid flow inside and outside of the droplet is described by the Stokes and continuity equations. The dimensionless forms of these equations are

The boundary conditions at the interface are as follows.

(i) Continuity of velocity:

(2.3)where \begin{equation} \boldsymbol{u}^{\boldsymbol{in}} = \boldsymbol{u}^{{\boldsymbol{out}}} = \boldsymbol{u}_{{\boldsymbol{s}}}, \end{equation}

\begin{equation} \boldsymbol{u}^{\boldsymbol{in}} = \boldsymbol{u}^{{\boldsymbol{out}}} = \boldsymbol{u}_{{\boldsymbol{s}}}, \end{equation} $\boldsymbol {u}_{\boldsymbol {s}}$ represents the velocity of the interface.

$\boldsymbol {u}_{\boldsymbol {s}}$ represents the velocity of the interface.(ii) Force balance:

(2.4) \begin{equation} (\boldsymbol{\tau}^{in} - \boldsymbol{\tau}^{out}) \boldsymbol{\cdot} \boldsymbol{n} = \boldsymbol{f}_{\boldsymbol{\mu}} + \boldsymbol{f}_{\boldsymbol{\kappa}} + \frac{1}{Ca} \left( \boldsymbol{\nabla}_{\boldsymbol{s}}\sigma - \sigma\boldsymbol{n}\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n} \right). \end{equation}

\begin{equation} (\boldsymbol{\tau}^{in} - \boldsymbol{\tau}^{out}) \boldsymbol{\cdot} \boldsymbol{n} = \boldsymbol{f}_{\boldsymbol{\mu}} + \boldsymbol{f}_{\boldsymbol{\kappa}} + \frac{1}{Ca} \left( \boldsymbol{\nabla}_{\boldsymbol{s}}\sigma - \sigma\boldsymbol{n}\boldsymbol{\nabla}\boldsymbol{\cdot}\boldsymbol{n} \right). \end{equation}

In (2.4), ![]() $\boldsymbol {\tau }^{in} - \boldsymbol {\tau }^{out}$ is the traction jump across the interface,

$\boldsymbol {\tau }^{in} - \boldsymbol {\tau }^{out}$ is the traction jump across the interface, ![]() $Ca=G^{\prime }\eta ^{\prime } R^{\prime }/\sigma _{eq}^{\prime }$ represents the capillary number,

$Ca=G^{\prime }\eta ^{\prime } R^{\prime }/\sigma _{eq}^{\prime }$ represents the capillary number, ![]() $\sigma$ is the dimensionless surface tension and

$\sigma$ is the dimensionless surface tension and ![]() $\boldsymbol {n}$ is the outward-pointing normal. The expressions for the interfacial shear traction

$\boldsymbol {n}$ is the outward-pointing normal. The expressions for the interfacial shear traction ![]() $\boldsymbol {f}_{\boldsymbol {\mu }}$ and the interfacial dilational traction

$\boldsymbol {f}_{\boldsymbol {\mu }}$ and the interfacial dilational traction ![]() $\boldsymbol {f}_{\boldsymbol {\kappa }}$ in (2.4) are given by the Boussinesq–Scriven constitutive relationship (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960):

$\boldsymbol {f}_{\boldsymbol {\kappa }}$ in (2.4) are given by the Boussinesq–Scriven constitutive relationship (Boussinesq Reference Boussinesq1913; Scriven Reference Scriven1960):

In the above expressions, ![]() $\boldsymbol{\mathsf{P}} = \boldsymbol{\mathsf{I}}-\boldsymbol {nn}$ is the projection operator on the surface,

$\boldsymbol{\mathsf{P}} = \boldsymbol{\mathsf{I}}-\boldsymbol {nn}$ is the projection operator on the surface, ![]() $\boldsymbol {\nabla }_{\boldsymbol {s}} = \boldsymbol{\mathsf{P}} \boldsymbol {\cdot} \boldsymbol {\nabla }$ is the surface gradient,

$\boldsymbol {\nabla }_{\boldsymbol {s}} = \boldsymbol{\mathsf{P}} \boldsymbol {\cdot} \boldsymbol {\nabla }$ is the surface gradient, ![]() $Bq_{\mu }={\eta _\mu ^{\prime }}/{R^{\prime }\eta ^{\prime }}$ is the Boussinesq number for the surface shear viscosity and

$Bq_{\mu }={\eta _\mu ^{\prime }}/{R^{\prime }\eta ^{\prime }}$ is the Boussinesq number for the surface shear viscosity and ![]() $Bq_{\kappa }={\eta _\kappa ^{\prime }}/{R^{\prime }\eta ^{\prime }}$ is the Boussinesq number for the surface dilational viscosity.

$Bq_{\kappa }={\eta _\kappa ^{\prime }}/{R^{\prime }\eta ^{\prime }}$ is the Boussinesq number for the surface dilational viscosity.

As an alternative way of quantifying the surface viscous effects, we introduce additional dimensionless parameters ![]() $Bq=Bq_\mu +Bq_\kappa$ and interfacial viscosity ratio

$Bq=Bq_\mu +Bq_\kappa$ and interfacial viscosity ratio ![]() $\lambda _{ds}={\eta _\kappa ^{\prime }}/{\eta _\mu ^{\prime }}$. The former represents the ratio of combined interfacial forces to the bulk viscous forces, while the latter represents the relative ratio of surface dilational to shear viscosity.

$\lambda _{ds}={\eta _\kappa ^{\prime }}/{\eta _\mu ^{\prime }}$. The former represents the ratio of combined interfacial forces to the bulk viscous forces, while the latter represents the relative ratio of surface dilational to shear viscosity.

The changes in surfactant concentration ![]() $\varGamma$ along the droplet's surface are taken into account using the time-dependent convection–diffusion equation (Stone Reference Stone1990; Wong, Rumschitzki & Maldarelli Reference Wong, Rumschitzki and Maldarelli1996):

$\varGamma$ along the droplet's surface are taken into account using the time-dependent convection–diffusion equation (Stone Reference Stone1990; Wong, Rumschitzki & Maldarelli Reference Wong, Rumschitzki and Maldarelli1996):

where ![]() $Pe_s = {Ca R^{\prime }\sigma _{eq}^{\prime } }/{ D_s^{\prime }\eta ^{\prime }}$ is the surface Péclet number,

$Pe_s = {Ca R^{\prime }\sigma _{eq}^{\prime } }/{ D_s^{\prime }\eta ^{\prime }}$ is the surface Péclet number, ![]() $\boldsymbol {u}_{\boldsymbol {t}}$ is the tangential component of the interfacial velocity

$\boldsymbol {u}_{\boldsymbol {t}}$ is the tangential component of the interfacial velocity ![]() $\boldsymbol {u}_{\boldsymbol {s}}$ and

$\boldsymbol {u}_{\boldsymbol {s}}$ and ![]() $D_s^{\prime }$ is the surface diffusivity of the surfactant molecules. The surface Péclet number is the ratio of surface convection rate to the surface diffusion rate of the surfactant. In (2.7), the interpretation of the time derivative is such that the surface coordinates are fixed. In our numerical code, we displace the grid points in the direction normal to the interface. Therefore, the term

$D_s^{\prime }$ is the surface diffusivity of the surfactant molecules. The surface Péclet number is the ratio of surface convection rate to the surface diffusion rate of the surfactant. In (2.7), the interpretation of the time derivative is such that the surface coordinates are fixed. In our numerical code, we displace the grid points in the direction normal to the interface. Therefore, the term ![]() $-\dot {\boldsymbol {x}} \boldsymbol {\cdot} \boldsymbol {\nabla }_s \varGamma$ (that arises because of the displacement of the grid points along the surface as the droplet deforms) is zero in the evolution equation given by Wong et al. (Reference Wong, Rumschitzki and Maldarelli1996).

$-\dot {\boldsymbol {x}} \boldsymbol {\cdot} \boldsymbol {\nabla }_s \varGamma$ (that arises because of the displacement of the grid points along the surface as the droplet deforms) is zero in the evolution equation given by Wong et al. (Reference Wong, Rumschitzki and Maldarelli1996).

We consider the Langmuir equation of state to relate the surface tension to the surfactant concentration at the interface:

In the above equation, ![]() $\sigma _c^{\prime }$ is the surface tension of a clean interface without surfactant. The dimensionless parameter

$\sigma _c^{\prime }$ is the surface tension of a clean interface without surfactant. The dimensionless parameter ![]() $E={R_G^{\prime } T^{\prime } \varGamma _\infty ^{\prime }}/{\sigma _{eq}^{\prime }}$ is the surface elasticity number, where

$E={R_G^{\prime } T^{\prime } \varGamma _\infty ^{\prime }}/{\sigma _{eq}^{\prime }}$ is the surface elasticity number, where ![]() $R_G^{\prime }$ is the ideal gas constant,

$R_G^{\prime }$ is the ideal gas constant, ![]() $T^{\prime }$ is the absolute temperature and

$T^{\prime }$ is the absolute temperature and ![]() $\varGamma _\infty ^{\prime }$ is the maximum packing density for a given surfactant system.

$\varGamma _\infty ^{\prime }$ is the maximum packing density for a given surfactant system.

At initial time ![]() $t=0$, we assume a homogeneous distribution of surfactant over the interface of the droplet (

$t=0$, we assume a homogeneous distribution of surfactant over the interface of the droplet (![]() $\varGamma =1$) and (2.8) can be rewritten as

$\varGamma =1$) and (2.8) can be rewritten as

In the case of non-homogeneous distribution of surfactant over the droplet's surface, the surface viscosities can vary strongly with surface pressure ![]() $\varPi ^{\prime } = \sigma _c^{\prime } - \sigma ^{\prime }$, as has been explored in several experimental studies (Kurtz, Lange & Fuller Reference Kurtz, Lange and Fuller2006; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Kim et al. Reference Kim, Choi, Zell, Squires and Zasadzinski2013; Samaniuk & Vermant Reference Samaniuk and Vermant2014). The dependence of surface viscosity on surface tension is taken into account using the following expressions (Manikantan & Squires Reference Manikantan and Squires2017):

$\varPi ^{\prime } = \sigma _c^{\prime } - \sigma ^{\prime }$, as has been explored in several experimental studies (Kurtz, Lange & Fuller Reference Kurtz, Lange and Fuller2006; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Kim et al. Reference Kim, Choi, Zell, Squires and Zasadzinski2013; Samaniuk & Vermant Reference Samaniuk and Vermant2014). The dependence of surface viscosity on surface tension is taken into account using the following expressions (Manikantan & Squires Reference Manikantan and Squires2017):

where ![]() $+$ and

$+$ and ![]() $-$ signs represent a pressure-thickening and pressure-thinning surfactant, respectively;

$-$ signs represent a pressure-thickening and pressure-thinning surfactant, respectively; ![]() ${\eta _{\mu, eq}^{\prime }}$ and

${\eta _{\mu, eq}^{\prime }}$ and ![]() ${\eta _{\kappa, eq}^{\prime }}$ denote the equilibrium shear and dilational surface viscosity at the initial value of surface pressure

${\eta _{\kappa, eq}^{\prime }}$ denote the equilibrium shear and dilational surface viscosity at the initial value of surface pressure ![]() $\varPi _{eq}^{\prime }$; and

$\varPi _{eq}^{\prime }$; and ![]() $\varPi _c^{\prime }$ is the pressure scale over which significant surface viscosity changes occur (Manikantan & Squires Reference Manikantan and Squires2017).

$\varPi _c^{\prime }$ is the pressure scale over which significant surface viscosity changes occur (Manikantan & Squires Reference Manikantan and Squires2017).

The dimensionless forms of (2.10) and (2.11) are

In the above equations, ![]() $\varPi _c=\varPi _c^{\prime }/\sigma _{eq}^{\prime }$ is the dimensionless surface pressure scale.

$\varPi _c=\varPi _c^{\prime }/\sigma _{eq}^{\prime }$ is the dimensionless surface pressure scale.

The dimensionless parameters are summarized in table 1. The ranges of surface parameters (![]() $Bq_\mu, Bq_\kappa, \varPi _c, E$) explored in this study are based on their experimental values reported in previous literature (Brooks et al. Reference Brooks, Fuller, Frank and Robertson1999; Kurtz et al. Reference Kurtz, Lange and Fuller2006; Georgieva et al. Reference Georgieva, Schmitt, Leal-Calderon and Langevin2009; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Kim et al. Reference Kim, Choi, Zell, Squires and Zasadzinski2013; Verwijlen et al. Reference Verwijlen, Moldenaers and Vermant2013; Hermans & Vermant Reference Hermans and Vermant2014; Samaniuk & Vermant Reference Samaniuk and Vermant2014; Zell et al. Reference Zell, Nowbahar, Mansard, Leal, Deshmukh, Mecca, Tucker and Squires2014; Manikantan & Squires Reference Manikantan and Squires2017; Singh & Narsimhan Reference Singh and Narsimhan2021). The surface Péclet number is based on surface diffusivity measurements listed in Shmyrov & Mizev (Reference Shmyrov and Mizev2019) that are collected from various sources. The surface diffusivity can vary widely depending on the phase behaviour of the adsorbed surfactant. A rule of thumb is that many macroscopic droplets (millimetre or above) will have

$Bq_\mu, Bq_\kappa, \varPi _c, E$) explored in this study are based on their experimental values reported in previous literature (Brooks et al. Reference Brooks, Fuller, Frank and Robertson1999; Kurtz et al. Reference Kurtz, Lange and Fuller2006; Georgieva et al. Reference Georgieva, Schmitt, Leal-Calderon and Langevin2009; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Kim et al. Reference Kim, Choi, Zell, Squires and Zasadzinski2013; Verwijlen et al. Reference Verwijlen, Moldenaers and Vermant2013; Hermans & Vermant Reference Hermans and Vermant2014; Samaniuk & Vermant Reference Samaniuk and Vermant2014; Zell et al. Reference Zell, Nowbahar, Mansard, Leal, Deshmukh, Mecca, Tucker and Squires2014; Manikantan & Squires Reference Manikantan and Squires2017; Singh & Narsimhan Reference Singh and Narsimhan2021). The surface Péclet number is based on surface diffusivity measurements listed in Shmyrov & Mizev (Reference Shmyrov and Mizev2019) that are collected from various sources. The surface diffusivity can vary widely depending on the phase behaviour of the adsorbed surfactant. A rule of thumb is that many macroscopic droplets (millimetre or above) will have ![]() $Pe_s \gg 1$ while those that are small (e.g. nanoemulsions or microemulsions) will have

$Pe_s \gg 1$ while those that are small (e.g. nanoemulsions or microemulsions) will have ![]() $Pe_s \sim O(1)$ or smaller.

$Pe_s \sim O(1)$ or smaller.

Table 1. Dimensionless parameters.

2.3. Numerical implementation and validation

We implement axisymmetric boundary-element simulations to numerically compute the droplet's interfacial velocity. The velocity at the interfacial location ![]() $\boldsymbol {x}_{\boldsymbol {0}}$ can be expressed as

$\boldsymbol {x}_{\boldsymbol {0}}$ can be expressed as

In the above equation, ![]() $\boldsymbol{\mathsf{M}}$ and

$\boldsymbol{\mathsf{M}}$ and ![]() $\boldsymbol{\mathsf{q}}$ represent the single-layer and the double-layer potentials (Pozrikidis Reference Pozrikidis1990, Reference Pozrikidis1992),

$\boldsymbol{\mathsf{q}}$ represent the single-layer and the double-layer potentials (Pozrikidis Reference Pozrikidis1990, Reference Pozrikidis1992), ![]() $[[\boldsymbol {\tau } \boldsymbol {\cdot}\boldsymbol {n}]]$ is the traction jump across the interface and

$[[\boldsymbol {\tau } \boldsymbol {\cdot}\boldsymbol {n}]]$ is the traction jump across the interface and ![]() ${\rm d}l$ is the differential arclength along the droplet contour.

${\rm d}l$ is the differential arclength along the droplet contour.

The droplet surface is discretized into ![]() $N$ elements connecting

$N$ elements connecting ![]() $N+1$ nodes. The detailed numerical implementation to solve the boundary-integral equation (2.14) and the convection–diffusion equation (2.7) can be found in the axisymmetric code developed in Singh & Narsimhan (Reference Singh and Narsimhan2021). A typical simulation starts with

$N+1$ nodes. The detailed numerical implementation to solve the boundary-integral equation (2.14) and the convection–diffusion equation (2.7) can be found in the axisymmetric code developed in Singh & Narsimhan (Reference Singh and Narsimhan2021). A typical simulation starts with ![]() $N=100$ nodes on a spherical droplet interface. The time step

$N=100$ nodes on a spherical droplet interface. The time step ![]() $\Delta t$ is set as

$\Delta t$ is set as ![]() $(2\unicode{x2013}6)\times 10^{-3} Ca$ to update the droplet shape using the numerical scheme and the re-meshing procedure described in Singh & Narsimhan (Reference Singh and Narsimhan2021). To ensure that the total surfactant is conserved on the droplet's surface, we rescale the surfactant concentration at each time step. Therefore, the surfactant concentration integrated over the interface is constant over time. In the absence of such rescaling, we find that the error in total surfactant concentration integrated over the interface is less than 0.6 % for the simulations shown in the paper. The droplet is considered to have attained a steady-state deformation when the interfacial normal velocity

$(2\unicode{x2013}6)\times 10^{-3} Ca$ to update the droplet shape using the numerical scheme and the re-meshing procedure described in Singh & Narsimhan (Reference Singh and Narsimhan2021). To ensure that the total surfactant is conserved on the droplet's surface, we rescale the surfactant concentration at each time step. Therefore, the surfactant concentration integrated over the interface is constant over time. In the absence of such rescaling, we find that the error in total surfactant concentration integrated over the interface is less than 0.6 % for the simulations shown in the paper. The droplet is considered to have attained a steady-state deformation when the interfacial normal velocity ![]() $|\boldsymbol {u}_{\boldsymbol {n}}|<0.01$ at all collocation points. The critical capillary number

$|\boldsymbol {u}_{\boldsymbol {n}}|<0.01$ at all collocation points. The critical capillary number ![]() $Ca_C$ denotes the largest value of

$Ca_C$ denotes the largest value of ![]() $Ca$ below which the droplet attains a steady-state deformation under flow.

$Ca$ below which the droplet attains a steady-state deformation under flow.

To validate our code, we compare our results with boundary-element simulations from Pawar & Stebe (Reference Pawar and Stebe1996). Figure 2 shows the variation of Taylor deformation parameter ![]() $D_{Taylor}$ with capillary number

$D_{Taylor}$ with capillary number ![]() $Ca$ for a clean droplet with viscosity ratio

$Ca$ for a clean droplet with viscosity ratio ![]() $\lambda =1$. In the same plot, we also compare our numerical results with those of second-order perturbation theories developed in previous studies (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020) and the lowest-order perturbation analysis from Flumerfelt (Reference Flumerfelt1980). The lowest-order perturbation theories solve the droplet shape up to

$\lambda =1$. In the same plot, we also compare our numerical results with those of second-order perturbation theories developed in previous studies (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020) and the lowest-order perturbation analysis from Flumerfelt (Reference Flumerfelt1980). The lowest-order perturbation theories solve the droplet shape up to ![]() ${O}{(Ca)}$ for

${O}{(Ca)}$ for ![]() $Ca \ll 1$, while the second-order theories solve the shape up to

$Ca \ll 1$, while the second-order theories solve the shape up to ![]() ${O} {(Ca^{2})}$ (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Narsimhan Reference Narsimhan2019). At

${O} {(Ca^{2})}$ (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Narsimhan Reference Narsimhan2019). At ![]() ${O} {(Ca)}$, the analytical expression of the Taylor deformation parameter for a droplet with surface shear and dilational viscosity under uniaxial extensional flow is given as (Taylor Reference Taylor1934; Flumerfelt Reference Flumerfelt1980)

${O} {(Ca)}$, the analytical expression of the Taylor deformation parameter for a droplet with surface shear and dilational viscosity under uniaxial extensional flow is given as (Taylor Reference Taylor1934; Flumerfelt Reference Flumerfelt1980)

Our results compare well with the numerical simulation from Pawar & Stebe (Reference Pawar and Stebe1996) and the second-order perturbation theories at all ![]() $Ca$ values. At

$Ca$ values. At ![]() $Ca>0.01$, we see that the lowest-order perturbation analysis shows deviations from the data predicted from simulations and underpredicts the

$Ca>0.01$, we see that the lowest-order perturbation analysis shows deviations from the data predicted from simulations and underpredicts the ![]() $D_{Taylor}$ values.

$D_{Taylor}$ values.

Figure 2. Plot of ![]() $D_{Taylor}$ versus

$D_{Taylor}$ versus ![]() $Ca$ for a clean droplet without surfactant and viscosity ratio

$Ca$ for a clean droplet without surfactant and viscosity ratio ![]() $\lambda =1.0$. The blue dots represent our numerical results and the red triangles represent boundary-element simulations from Pawar & Stebe (Reference Pawar and Stebe1996). The dashed blue curve is from second-order perturbation analysis (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Singh & Narsimhan Reference Singh and Narsimhan2020), and the black solid curve is the lowest-order perturbation analysis from Flumerfelt (Reference Flumerfelt1980).

$\lambda =1.0$. The blue dots represent our numerical results and the red triangles represent boundary-element simulations from Pawar & Stebe (Reference Pawar and Stebe1996). The dashed blue curve is from second-order perturbation analysis (Barthes-Biesel & Acrivos Reference Barthes-Biesel and Acrivos1973; Vlahovska et al. Reference Vlahovska, Bławzdziewicz and Loewenberg2009; Singh & Narsimhan Reference Singh and Narsimhan2020), and the black solid curve is the lowest-order perturbation analysis from Flumerfelt (Reference Flumerfelt1980).

3. Results: droplet deformation and breakup

In §§ 3.1–3.3, we explore the effect of surface viscosity and surfactant transport on the deformation and breakup of a droplet placed in an extensional flow.

3.1. Comparison with small deformation perturbation theories for constant surface viscosity

In this section, we discuss the effect of constant surface viscosity on the steady-state deformation and the critical capillary number ![]() $Ca_C$ for droplet breakup. This analysis assumes that surface tension is constant and that surfactant is homogeneously distributed on the interface. Surfactant transport effects are neglected to analyse the isolated impact of interfacial viscosity on droplet dynamics. Sections 3.2 and 3.3 examine the coupling between interfacial viscosity, Marangoni stresses and surface dilution.

$Ca_C$ for droplet breakup. This analysis assumes that surface tension is constant and that surfactant is homogeneously distributed on the interface. Surfactant transport effects are neglected to analyse the isolated impact of interfacial viscosity on droplet dynamics. Sections 3.2 and 3.3 examine the coupling between interfacial viscosity, Marangoni stresses and surface dilution.

Figure 3 shows the variation of ![]() $D_{Taylor}$ with

$D_{Taylor}$ with ![]() $Bq=Bq_\kappa +Bq_\mu$ for a droplet with interfacial viscosity ratio

$Bq=Bq_\kappa +Bq_\mu$ for a droplet with interfacial viscosity ratio ![]() $\lambda _{ds}= Bq_{\kappa }/Bq_{\mu }=1$. We observe that at a given capillary number, the steady-state deformation

$\lambda _{ds}= Bq_{\kappa }/Bq_{\mu }=1$. We observe that at a given capillary number, the steady-state deformation ![]() $D_{Taylor}$ of the droplet decreases upon increasing

$D_{Taylor}$ of the droplet decreases upon increasing ![]() $Bq$. Our numerical results compare well with those of the small deformation perturbation theories at

$Bq$. Our numerical results compare well with those of the small deformation perturbation theories at ![]() ${O} {(Ca^{2})}$ (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020). Again, we see that the lowest-order perturbation analysis using (2.15) underpredicts the

${O} {(Ca^{2})}$ (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020). Again, we see that the lowest-order perturbation analysis using (2.15) underpredicts the ![]() $D_{Taylor}$ values, and this effect is more significant at

$D_{Taylor}$ values, and this effect is more significant at ![]() $Ca=0.05$ than at

$Ca=0.05$ than at ![]() $Ca=0.01$.

$Ca=0.01$.

Figure 3. Plots of ![]() $D_{Taylor}$ versus

$D_{Taylor}$ versus ![]() $Bq$ for a droplet with interfacial viscosity ratio

$Bq$ for a droplet with interfacial viscosity ratio ![]() $\lambda _{ds}=1$ at capillary number values 0.01 and 0.05. The dots represent our numerical results, dashed curves are from second-order perturbation theories (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020) and bold curves are from using first-order perturbation theory (2.15).

$\lambda _{ds}=1$ at capillary number values 0.01 and 0.05. The dots represent our numerical results, dashed curves are from second-order perturbation theories (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020) and bold curves are from using first-order perturbation theory (2.15).

Figure 4 shows the variation of ![]() $D_{Taylor}$ with interfacial viscosity ratio

$D_{Taylor}$ with interfacial viscosity ratio ![]() $\lambda _{ds}$ for a droplet with viscosity ratio

$\lambda _{ds}$ for a droplet with viscosity ratio ![]() $\lambda =1$,

$\lambda =1$, ![]() $Ca=0.05$ at

$Ca=0.05$ at ![]() $Bq$ values of 2, 5 and 10. Ratio

$Bq$ values of 2, 5 and 10. Ratio ![]() $\lambda _{ds}=0$ represents a droplet with pure surface shear viscosity, and

$\lambda _{ds}=0$ represents a droplet with pure surface shear viscosity, and ![]() $\lambda _{ds}=\infty$ represents a droplet with pure surface dilational viscosity. The horizontal dashed line shows

$\lambda _{ds}=\infty$ represents a droplet with pure surface dilational viscosity. The horizontal dashed line shows ![]() $D_{Taylor}$ for a clean droplet without surfactant at

$D_{Taylor}$ for a clean droplet without surfactant at ![]() $Ca=0.05$ and

$Ca=0.05$ and ![]() $\lambda =1$. We observe that at

$\lambda =1$. We observe that at ![]() $\lambda _{ds} \approx 2.0$,

$\lambda _{ds} \approx 2.0$, ![]() $D_{Taylor}$ of a droplet with surface viscosity is the same as that of a clean droplet for different

$D_{Taylor}$ of a droplet with surface viscosity is the same as that of a clean droplet for different ![]() $Bq$ values. Droplets with

$Bq$ values. Droplets with ![]() $\lambda _{ds}$ below this critical value exhibit smaller deformations than a clean droplet, and the deformation decreases as the interfacial effects (

$\lambda _{ds}$ below this critical value exhibit smaller deformations than a clean droplet, and the deformation decreases as the interfacial effects (![]() $Bq$) increase. Droplets with

$Bq$) increase. Droplets with ![]() $\lambda _{ds}$ above the critical value demonstrate the opposite effect – i.e. they exhibit larger deformations than clean droplets, and the deformation increases as the interfacial effects (

$\lambda _{ds}$ above the critical value demonstrate the opposite effect – i.e. they exhibit larger deformations than clean droplets, and the deformation increases as the interfacial effects (![]() $Bq$) increase. We observe qualitatively similar behaviour if we examine droplets at different viscosity ratios

$Bq$) increase. We observe qualitatively similar behaviour if we examine droplets at different viscosity ratios ![]() $\lambda$. The critical

$\lambda$. The critical ![]() $\lambda _{ds}$ where the droplet deformation is the same as that for a clean droplet shifts to

$\lambda _{ds}$ where the droplet deformation is the same as that for a clean droplet shifts to ![]() $\lambda _{ds}=0.9$ for a droplet with viscosity ratio

$\lambda _{ds}=0.9$ for a droplet with viscosity ratio ![]() $\lambda =0.1$ (see figure 5), while the critical value shifts to

$\lambda =0.1$ (see figure 5), while the critical value shifts to ![]() $\lambda _{ds} = 40$ for a droplet with viscosity ratio

$\lambda _{ds} = 40$ for a droplet with viscosity ratio ![]() $\lambda = 10$ (see figure 6).

$\lambda = 10$ (see figure 6).

Figure 4. Plots of ![]() $D_{Taylor}$ versus

$D_{Taylor}$ versus ![]() $\lambda _{ds}$ for a droplet with viscosity ratio

$\lambda _{ds}$ for a droplet with viscosity ratio ![]() $\lambda =1$,

$\lambda =1$, ![]() $Ca=0.05$ and

$Ca=0.05$ and ![]() $Bq$ values of 2, 5 and 10. Here

$Bq$ values of 2, 5 and 10. Here ![]() $D_{Taylor}$ for a clean droplet without surfactant at

$D_{Taylor}$ for a clean droplet without surfactant at ![]() $Ca=0.05$ and

$Ca=0.05$ and ![]() $\lambda =1$ is shown using a horizontal black dashed line.

$\lambda =1$ is shown using a horizontal black dashed line.

Figure 5. Plots of ![]() $D_{Taylor}$ versus

$D_{Taylor}$ versus ![]() $\lambda _{ds}$ for a droplet with viscosity ratio

$\lambda _{ds}$ for a droplet with viscosity ratio ![]() $\lambda =0.1$,

$\lambda =0.1$, ![]() $Ca=0.05$ and at

$Ca=0.05$ and at ![]() $Bq$ values of 2, 5 and 10. Here

$Bq$ values of 2, 5 and 10. Here ![]() $D_{Taylor}$ for a clean droplet without surfactant at

$D_{Taylor}$ for a clean droplet without surfactant at ![]() $Ca=0.05$ and

$Ca=0.05$ and ![]() $\lambda =0.1$ is shown using a horizontal black dashed line.

$\lambda =0.1$ is shown using a horizontal black dashed line.

Figure 6. Plots of ![]() $D_{Taylor}$ versus

$D_{Taylor}$ versus ![]() $\lambda _{ds}$ for a droplet with viscosity ratio

$\lambda _{ds}$ for a droplet with viscosity ratio ![]() $\lambda =10$,

$\lambda =10$, ![]() $Ca=0.05$ and at

$Ca=0.05$ and at ![]() $Bq$ values of 2, 5 and 10. Here

$Bq$ values of 2, 5 and 10. Here ![]() $D_{Taylor}$ for a clean droplet without surfactant at

$D_{Taylor}$ for a clean droplet without surfactant at ![]() $Ca=0.05$ and

$Ca=0.05$ and ![]() $\lambda =10$ is shown using a horizontal black dashed line.

$\lambda =10$ is shown using a horizontal black dashed line.

The experimentally reported values of surface dilational viscosity are found to be much larger than surface shear viscosity as ![]() $\lambda _{ds}>{O} {(1)}$ for most interfacial monolayers. For instance, the interfacial viscosity ratio estimates of lipid monolayer dipalmitoylphosphatidylcholine and dimyristoylphosphatidylethanolamine are reported to be

$\lambda _{ds}>{O} {(1)}$ for most interfacial monolayers. For instance, the interfacial viscosity ratio estimates of lipid monolayer dipalmitoylphosphatidylcholine and dimyristoylphosphatidylethanolamine are reported to be ![]() $\lambda _{ds} \sim {O} (10^{5})$ (Krägel et al. Reference Krägel, Kretzschmar, Li, Loglio, Miller and Möhwald1996; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011). Surface rheological studies of various interfacial monolayers have shown

$\lambda _{ds} \sim {O} (10^{5})$ (Krägel et al. Reference Krägel, Kretzschmar, Li, Loglio, Miller and Möhwald1996; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011). Surface rheological studies of various interfacial monolayers have shown ![]() $\lambda _{ds} \sim {O} (10^{3})$ for poly(

$\lambda _{ds} \sim {O} (10^{3})$ for poly(![]() $t$-butyl methacrylate) system (Krägel et al. Reference Krägel, Kretzschmar, Li, Loglio, Miller and Möhwald1996; Samaniuk & Vermant Reference Samaniuk and Vermant2014),

$t$-butyl methacrylate) system (Krägel et al. Reference Krägel, Kretzschmar, Li, Loglio, Miller and Möhwald1996; Samaniuk & Vermant Reference Samaniuk and Vermant2014), ![]() $\lambda _{ds} \sim {O} (10^{4})$ for hexadecanol interface (Verwijlen et al. Reference Verwijlen, Moldenaers and Vermant2013; Samaniuk & Vermant Reference Samaniuk and Vermant2014),

$\lambda _{ds} \sim {O} (10^{4})$ for hexadecanol interface (Verwijlen et al. Reference Verwijlen, Moldenaers and Vermant2013; Samaniuk & Vermant Reference Samaniuk and Vermant2014), ![]() $\lambda _{ds} \sim {O} (1)$ for protein

$\lambda _{ds} \sim {O} (1)$ for protein ![]() $\beta$-casein monolayer (Freer et al. Reference Freer, Yim, Fuller and Radke2004; Erni, Windhab & Fischer Reference Erni, Windhab and Fischer2011) and

$\beta$-casein monolayer (Freer et al. Reference Freer, Yim, Fuller and Radke2004; Erni, Windhab & Fischer Reference Erni, Windhab and Fischer2011) and ![]() $\lambda _{ds} \sim {O} (10^{6})$ for viscoelastic globular protein ovalbumin interface (Erni et al. Reference Erni, Fischer, Windhab, Kusnezov, Stettin and Läuger2003; Xiong et al. Reference Xiong, Ren, Tian, Yang, Li and Li2018). The results shown in figures 4, 5 and 6 suggest that the combined influence of surface shear and dilational viscosity will increase the droplet deformation compared with a clean droplet at the same capillary number for most surfactant systems.

$\lambda _{ds} \sim {O} (10^{6})$ for viscoelastic globular protein ovalbumin interface (Erni et al. Reference Erni, Fischer, Windhab, Kusnezov, Stettin and Läuger2003; Xiong et al. Reference Xiong, Ren, Tian, Yang, Li and Li2018). The results shown in figures 4, 5 and 6 suggest that the combined influence of surface shear and dilational viscosity will increase the droplet deformation compared with a clean droplet at the same capillary number for most surfactant systems.

The next part of this section examines how interfacial viscosity alters the critical capillary number ![]() $Ca_C$ for drop breakup. The critical capillary number

$Ca_C$ for drop breakup. The critical capillary number ![]() $Ca_C$ is defined as the largest value of

$Ca_C$ is defined as the largest value of ![]() $Ca$ below which the droplet will attain a steady-state deformation under flow (

$Ca$ below which the droplet will attain a steady-state deformation under flow (![]() $|\boldsymbol {u_n}|<0.01$ at all collocation points). Above this capillary number, the droplet will keep deforming and become unstable. Figure 7 compares the variation of

$|\boldsymbol {u_n}|<0.01$ at all collocation points). Above this capillary number, the droplet will keep deforming and become unstable. Figure 7 compares the variation of ![]() $Ca_C$ with viscosity ratio

$Ca_C$ with viscosity ratio ![]() $\lambda$ from the small deformation theories (represented by dashed lines) and numerical simulations (represented by bold lines). From figure 7(a), we can see that the surface dilational viscosity reduces

$\lambda$ from the small deformation theories (represented by dashed lines) and numerical simulations (represented by bold lines). From figure 7(a), we can see that the surface dilational viscosity reduces ![]() $Ca_C$ of the droplet compared with a clean droplet at the same viscosity ratio

$Ca_C$ of the droplet compared with a clean droplet at the same viscosity ratio ![]() $\lambda$. When

$\lambda$. When ![]() $\lambda >4$, we observe that

$\lambda >4$, we observe that ![]() $Ca_C$ of a droplet with dilational viscosity is nearly the same as

$Ca_C$ of a droplet with dilational viscosity is nearly the same as ![]() $Ca_C$ of a clean droplet from both theory and simulations. In contrast, we observe that the surface shear viscosity increases

$Ca_C$ of a clean droplet from both theory and simulations. In contrast, we observe that the surface shear viscosity increases ![]() $Ca_C$ compared with a clean droplet at the same

$Ca_C$ compared with a clean droplet at the same ![]() $\lambda$ (figure 7b). From figure 7(c), we can see the effect of equal surface shear and dilational viscosities on

$\lambda$ (figure 7b). From figure 7(c), we can see the effect of equal surface shear and dilational viscosities on ![]() $Ca_C$. In this case, the

$Ca_C$. In this case, the ![]() $Ca_C$ values are lower than that of the clean droplet for viscosity ratio

$Ca_C$ values are lower than that of the clean droplet for viscosity ratio ![]() $\lambda <0.4$ and are higher than that of the clean droplet for viscosity ratio

$\lambda <0.4$ and are higher than that of the clean droplet for viscosity ratio ![]() $\lambda >0.4$. The numerical results from boundary-element simulations are in good qualitative agreement with the small deformation theories for the three cases shown in figure 7. Previous studies examining clean droplets under extensional flow have also reported the

$\lambda >0.4$. The numerical results from boundary-element simulations are in good qualitative agreement with the small deformation theories for the three cases shown in figure 7. Previous studies examining clean droplets under extensional flow have also reported the ![]() $Ca_C$ values from analytical theories to be within

$Ca_C$ values from analytical theories to be within ![]() $15\,\%$ agreement with the numerical results (Rallison & Acrivos Reference Rallison and Acrivos1978), which is what we observe here.

$15\,\%$ agreement with the numerical results (Rallison & Acrivos Reference Rallison and Acrivos1978), which is what we observe here.

Figure 7. Critical capillary number ![]() $Ca_C$ versus viscosity ratio

$Ca_C$ versus viscosity ratio ![]() $\lambda$ for a clean droplet and a droplet with surface viscosity. The solid lines correspond to boundary-element simulations, while the dashed lines correspond to second-order perturbation theories (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020). (a) Effect of surface dilational viscosity. (b) Effect of surface shear viscosity. (c) Effect of equal surface shear and dilational viscosity.

$\lambda$ for a clean droplet and a droplet with surface viscosity. The solid lines correspond to boundary-element simulations, while the dashed lines correspond to second-order perturbation theories (Narsimhan Reference Narsimhan2019; Singh & Narsimhan Reference Singh and Narsimhan2020). (a) Effect of surface dilational viscosity. (b) Effect of surface shear viscosity. (c) Effect of equal surface shear and dilational viscosity.

Figure 8 shows steady-state droplet shapes at ![]() $Ca=0.04$ for a droplet with pure surface shear viscosity

$Ca=0.04$ for a droplet with pure surface shear viscosity ![]() $Bq_\mu =2, Bq_\kappa =0$ (figure 8a,c) and a droplet with pure surface dilational viscosity (figure 8b,d) at viscosity ratio values

$Bq_\mu =2, Bq_\kappa =0$ (figure 8a,c) and a droplet with pure surface dilational viscosity (figure 8b,d) at viscosity ratio values ![]() $\lambda = 0.1$ and

$\lambda = 0.1$ and ![]() $\lambda = 10$. The vectors shown in the droplet's upper half represent the computed traction from interfacial viscosity (2.5) and (2.6). As can be seen from figure 8, the droplet shapes from boundary-element simulations (drawn using dashed lines) match well with the droplet shapes from second-order perturbation theories (drawn using red dots). For a clean droplet,

$\lambda = 10$. The vectors shown in the droplet's upper half represent the computed traction from interfacial viscosity (2.5) and (2.6). As can be seen from figure 8, the droplet shapes from boundary-element simulations (drawn using dashed lines) match well with the droplet shapes from second-order perturbation theories (drawn using red dots). For a clean droplet, ![]() $D_{Taylor}=0.137$ at

$D_{Taylor}=0.137$ at ![]() $\lambda =0.1$ and

$\lambda =0.1$ and ![]() $D_{Taylor}=0.187$ at

$D_{Taylor}=0.187$ at ![]() $\lambda =10$. In the case of a droplet with pure surface shear viscosity (figure 8a,c), the shear traction opposes the surface velocity gradients and reduces the droplet deformation compared with the clean droplet. For a droplet with pure dilational viscosity, the expression of dilational traction (2.5) mimics the formulation of variable surface tension. The influence of surface dilational viscosity can be seen as an ‘effective’ surface tension (Singh & Narsimhan Reference Singh and Narsimhan2021):

$\lambda =10$. In the case of a droplet with pure surface shear viscosity (figure 8a,c), the shear traction opposes the surface velocity gradients and reduces the droplet deformation compared with the clean droplet. For a droplet with pure dilational viscosity, the expression of dilational traction (2.5) mimics the formulation of variable surface tension. The influence of surface dilational viscosity can be seen as an ‘effective’ surface tension (Singh & Narsimhan Reference Singh and Narsimhan2021):

The negative divergence of velocity in the droplet's pole reduces the effective surface tension in the pole region, and we observe that the droplet with surface dilational viscosity is more deformed than a clean droplet at the same ![]() $Ca$ (figure 8b,d). The effect of surface dilational viscosity appears similar to the influence of surfactant convection. When a droplet is placed under extensional flow, the surfactant gets swept towards the droplet's pole. The higher surfactant concentration in the pole region reduces the effective surface tension and increases the droplet deformation (Pawar & Stebe Reference Pawar and Stebe1996; Feigl et al. Reference Feigl, Megias-Alguacil, Fischer and Windhab2007).

$Ca$ (figure 8b,d). The effect of surface dilational viscosity appears similar to the influence of surfactant convection. When a droplet is placed under extensional flow, the surfactant gets swept towards the droplet's pole. The higher surfactant concentration in the pole region reduces the effective surface tension and increases the droplet deformation (Pawar & Stebe Reference Pawar and Stebe1996; Feigl et al. Reference Feigl, Megias-Alguacil, Fischer and Windhab2007).

Figure 8. Steady-state droplet shapes at ![]() $Ca=0.04$ for four different cases: (a)

$Ca=0.04$ for four different cases: (a) ![]() $Bq_\mu =2, Bq_\kappa =0$ and

$Bq_\mu =2, Bq_\kappa =0$ and ![]() $\lambda =0.1$; (b)

$\lambda =0.1$; (b) ![]() $Bq_\mu =0, Bq_\kappa =2$ and

$Bq_\mu =0, Bq_\kappa =2$ and ![]() $\lambda =0.1$; (c)

$\lambda =0.1$; (c) ![]() $Bq_\mu =2, Bq_\kappa =0$ and

$Bq_\mu =2, Bq_\kappa =0$ and ![]() $\lambda =10$; (d)

$\lambda =10$; (d) ![]() $Bq_\mu =0, Bq_\kappa =2$ and

$Bq_\mu =0, Bq_\kappa =2$ and ![]() $\lambda =10$. Shapes drawn using red dots are from second-order perturbation theories (Narsimhan Reference Narsimhan2019) and shapes drawn with dashed lines are from boundary-element simulations. The vectors shown in the droplet's upper half represent the computed traction from interfacial viscosity (2.5) and (2.6). For a clean droplet,

$\lambda =10$. Shapes drawn using red dots are from second-order perturbation theories (Narsimhan Reference Narsimhan2019) and shapes drawn with dashed lines are from boundary-element simulations. The vectors shown in the droplet's upper half represent the computed traction from interfacial viscosity (2.5) and (2.6). For a clean droplet, ![]() $D_{Taylor}=0.137$ at

$D_{Taylor}=0.137$ at ![]() $\lambda =0.1$ and

$\lambda =0.1$ and ![]() $D_{Taylor}=0.187$ at

$D_{Taylor}=0.187$ at ![]() $\lambda =10$.

$\lambda =10$.

From figure 8, we can see that the interfacial traction acting on the droplet's surface is more significant at ![]() $\lambda =0.1$ than at

$\lambda =0.1$ than at ![]() $\lambda =10$ for both surface shear and dilational viscosity (see scale for heat map). As a result, the surface viscosity influences the droplet deformation and

$\lambda =10$ for both surface shear and dilational viscosity (see scale for heat map). As a result, the surface viscosity influences the droplet deformation and ![]() $Ca_C$ more strongly at lower values of viscosity ratio than higher values, as can be seen from figure 7.

$Ca_C$ more strongly at lower values of viscosity ratio than higher values, as can be seen from figure 7.

3.2. Combined influence of constant surface viscosity and surfactant transport

As the droplet deforms under extensional flow, the surfactant can get swept from the droplet's equator towards the droplet's poles leading to non-homogeneous surfactant distribution. In this section, we include the effect of Marangoni stresses on droplet deformation and breakup, assuming the surface viscosity remains constant on the interface.

Figure 9 shows the variation of ![]() $Ca_C$ with

$Ca_C$ with ![]() $\lambda _{ds}$ for a droplet with

$\lambda _{ds}$ for a droplet with ![]() $Bq=2$ at surface Péclet number values

$Bq=2$ at surface Péclet number values ![]() $0.01$,

$0.01$, ![]() $1$,

$1$, ![]() $10$ and

$10$ and ![]() $1000$. The values of dimensionless parameters are:

$1000$. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.2$ and

$E=0.2$ and ![]() $\varGamma _\infty ^{-1}=0.5$. The dashed horizontal lines in the figure denote

$\varGamma _\infty ^{-1}=0.5$. The dashed horizontal lines in the figure denote ![]() $Ca_C$ of a droplet without surface viscosity, i.e.

$Ca_C$ of a droplet without surface viscosity, i.e. ![]() $Bq=0$. We observe that the critical capillary number

$Bq=0$. We observe that the critical capillary number ![]() $Ca_C$ decreases upon increasing

$Ca_C$ decreases upon increasing ![]() $\lambda _{ds}$ and approaches

$\lambda _{ds}$ and approaches ![]() $Ca_C$ of a droplet with pure surface dilational viscosity at

$Ca_C$ of a droplet with pure surface dilational viscosity at ![]() $\lambda _{ds}=\infty$. The surface viscosity does not significantly impact droplet breakup at higher values of surface Péclet number (

$\lambda _{ds}=\infty$. The surface viscosity does not significantly impact droplet breakup at higher values of surface Péclet number (![]() $Pe_s=10$ and

$Pe_s=10$ and ![]() $Pe_s=1000$). We find the

$Pe_s=1000$). We find the ![]() $Ca_C$ values for a droplet with interfacial viscosity to be the same as that without interfacial viscosity at

$Ca_C$ values for a droplet with interfacial viscosity to be the same as that without interfacial viscosity at ![]() $Pe_s=1000$.

$Pe_s=1000$.

Figure 9. Variation of ![]() $Ca_C$ with

$Ca_C$ with ![]() $\lambda _{ds}$ for a droplet with

$\lambda _{ds}$ for a droplet with ![]() $Bq=2$ at

$Bq=2$ at ![]() $Pe_s$ values 0.01, 1, 10 and 1000. The dashed horizontal lines denote

$Pe_s$ values 0.01, 1, 10 and 1000. The dashed horizontal lines denote ![]() $Ca_C$ of the droplet in the absence of surface viscosity, i.e.

$Ca_C$ of the droplet in the absence of surface viscosity, i.e. ![]() $Bq=0$. The dimensionless parameters are:

$Bq=0$. The dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.2$ and

$E=0.2$ and ![]() $\varGamma _\infty ^{-1}=0.5$.

$\varGamma _\infty ^{-1}=0.5$.

Figure 10(a) shows the droplet shapes at ![]() $Pe_s=0.01$ and

$Pe_s=0.01$ and ![]() $Pe_s=1000$ for a droplet with interfacial viscosity

$Pe_s=1000$ for a droplet with interfacial viscosity ![]() $Bq=2$ and

$Bq=2$ and ![]() $\lambda _{ds}=1$. The values of dimensionless parameters are:

$\lambda _{ds}=1$. The values of dimensionless parameters are: ![]() $Ca=0.05$,

$Ca=0.05$, ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.4$ and

$E=0.4$ and ![]() $\varGamma _\infty ^{-1}=0.5$. The droplet at surface Péclet number

$\varGamma _\infty ^{-1}=0.5$. The droplet at surface Péclet number ![]() $Pe=0.01$ appears less deformed than the droplet at

$Pe=0.01$ appears less deformed than the droplet at ![]() $Pe=1000$. Figure 10(b) shows the variation of tangential interfacial traction and Marangoni forces acting along the droplet's surface with normalized arclength

$Pe=1000$. Figure 10(b) shows the variation of tangential interfacial traction and Marangoni forces acting along the droplet's surface with normalized arclength ![]() $s$ for the shapes shown in figure 10(a). At

$s$ for the shapes shown in figure 10(a). At ![]() $Pe=0.01$, we observe that the Marangoni effects are negligible compared with the surface viscosity effects. In contrast, at

$Pe=0.01$, we observe that the Marangoni effects are negligible compared with the surface viscosity effects. In contrast, at ![]() $Pe=1000$, the traction contribution from interfacial viscosity is much smaller than the Marangoni forces. As a result, the interfacial viscosity has a negligible impact on droplet deformation and breakup at large

$Pe=1000$, the traction contribution from interfacial viscosity is much smaller than the Marangoni forces. As a result, the interfacial viscosity has a negligible impact on droplet deformation and breakup at large ![]() $Pe_s$, and the

$Pe_s$, and the ![]() $Ca_C$ values approach the results for a droplet with only surfactant transport (as was observed in figure 9).

$Ca_C$ values approach the results for a droplet with only surfactant transport (as was observed in figure 9).

Figure 10. (a) Steady-state droplet shapes at ![]() $Pe_s=0.01$ and

$Pe_s=0.01$ and ![]() $Pe_s=1000$ for a droplet with

$Pe_s=1000$ for a droplet with ![]() $Bq=\!2$ and

$Bq=\!2$ and ![]() $\lambda _{ds}=\!1$. (b) Variation of tangential component of interfacial traction (shown by bold curves) and Marangoni traction (shown by dashed curves) with normalized arclength

$\lambda _{ds}=\!1$. (b) Variation of tangential component of interfacial traction (shown by bold curves) and Marangoni traction (shown by dashed curves) with normalized arclength ![]() $s$ for the droplet shapes shown in (a). The values of dimensionless parameters are:

$s$ for the droplet shapes shown in (a). The values of dimensionless parameters are: ![]() $Ca=0.050$,

$Ca=0.050$, ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.4$ and

$E=0.4$ and ![]() $\varGamma _\infty ^{-1}=0.5$.

$\varGamma _\infty ^{-1}=0.5$.

Figure 11 shows the variation of ![]() $Ca_C$ with

$Ca_C$ with ![]() $Bq$ for a droplet with equal surface shear and dilational viscosity

$Bq$ for a droplet with equal surface shear and dilational viscosity ![]() $\lambda _{ds}=1$. The values of dimensionless parameters are:

$\lambda _{ds}=1$. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.2$ and

$E=0.2$ and ![]() $\varGamma _\infty ^{-1}=0.5$. Similar to the case of constant surface viscosity (figure 7c), for a droplet with surfactant transport, we observe that the droplet with equal interfacial viscosities has a higher

$\varGamma _\infty ^{-1}=0.5$. Similar to the case of constant surface viscosity (figure 7c), for a droplet with surfactant transport, we observe that the droplet with equal interfacial viscosities has a higher ![]() $Ca_C$ than that of a droplet without interfacial viscosity. We observe that increasing the interfacial viscosity has a higher impact on

$Ca_C$ than that of a droplet without interfacial viscosity. We observe that increasing the interfacial viscosity has a higher impact on ![]() $Ca_C$ at

$Ca_C$ at ![]() $Pe_s=0.01$ than at

$Pe_s=0.01$ than at ![]() $Pe_s=10$. The interfacial viscosity has a negligible impact on

$Pe_s=10$. The interfacial viscosity has a negligible impact on ![]() $Ca_C$ at

$Ca_C$ at ![]() $Pe_s=1000$.

$Pe_s=1000$.

Figure 11. Variation of ![]() $Ca_C$ with

$Ca_C$ with ![]() $Bq=Bq_\mu +Bq_\kappa$ for a droplet with interfacial viscosity ratio

$Bq=Bq_\mu +Bq_\kappa$ for a droplet with interfacial viscosity ratio ![]() $\lambda _{ds}=1$ at surface Péclet number values

$\lambda _{ds}=1$ at surface Péclet number values ![]() $Pe_s=0.01$,

$Pe_s=0.01$, ![]() $1$,

$1$, ![]() $10$ and

$10$ and ![]() $1000$. The values of dimensionless parameters are:

$1000$. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.2$ and

$E=0.2$ and ![]() $\varGamma _\infty =2$.

$\varGamma _\infty =2$.

3.3. Influence of pressure-dependent surface viscosity

Previous literature has shown that the surface viscosity can change sharply with surface pressure (Kurtz et al. Reference Kurtz, Lange and Fuller2006; Kim et al. Reference Kim, Choi, Zasadzinski and Squires2011; Fuller & Vermant Reference Fuller and Vermant2012; Kim et al. Reference Kim, Choi, Zell, Squires and Zasadzinski2013; Samaniuk & Vermant Reference Samaniuk and Vermant2014). Here we discuss how the pressure-dependent surface shear and dilational viscosity enhance/reduce the droplet deformation and critical capillary number compared with the case of ![]() $\varPi$-independent surface viscosity. We include the effect of surfactant transport as in § 3.2, but now also let the surface viscosity vary with surfactant concentration.

$\varPi$-independent surface viscosity. We include the effect of surfactant transport as in § 3.2, but now also let the surface viscosity vary with surfactant concentration.

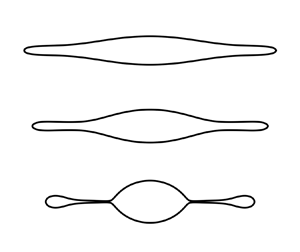

We first discuss the impact of pressure-dependent surface shear viscosity on droplet deformation and breakup. Figure 12 shows the evolution of droplet shapes with time for a pressure-thinning surfactant with ![]() $\varPi _c=0.25$ (shown in figure 12a) and a pressure-thickening surfactant with

$\varPi _c=0.25$ (shown in figure 12a) and a pressure-thickening surfactant with ![]() $\varPi _c=0.25$ (shown in figure 12b) at capillary number

$\varPi _c=0.25$ (shown in figure 12b) at capillary number ![]() $Ca=0.08$. The values of dimensionless parameters are:

$Ca=0.08$. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $Pe_s=0.01$,

$Pe_s=0.01$, ![]() $E=0.4$,

$E=0.4$, ![]() $\varGamma _\infty =2$,

$\varGamma _\infty =2$, ![]() $Bq_{\mu, {eq}}=2$ and

$Bq_{\mu, {eq}}=2$ and ![]() $Bq_{\kappa,{eq}}=0$. The droplet with

$Bq_{\kappa,{eq}}=0$. The droplet with ![]() $\varPi$-thinning surfactant eventually attains a stable shape under flow at time

$\varPi$-thinning surfactant eventually attains a stable shape under flow at time ![]() $t=5.4$. In contrast, at the same capillary number, the droplet with

$t=5.4$. In contrast, at the same capillary number, the droplet with ![]() $\varPi$-thickening surfactant deforms continuously with time and becomes unstable. In figure 13, we plot the variation of

$\varPi$-thickening surfactant deforms continuously with time and becomes unstable. In figure 13, we plot the variation of ![]() $Bq_\mu$ and surfactant concentration

$Bq_\mu$ and surfactant concentration ![]() $\varGamma$ with normalized arclength

$\varGamma$ with normalized arclength ![]() $s$ (

$s$ (![]() $s=0$ and

$s=0$ and ![]() $s=1$ at the droplet's two poles) for the droplet shapes shown in figures 12(a) and 12(b) at

$s=1$ at the droplet's two poles) for the droplet shapes shown in figures 12(a) and 12(b) at ![]() $t=5.4$. At

$t=5.4$. At ![]() $Pe=0.01$, the diffusion of the surfactant along the droplet's interface dominates over the surfactant convection. As a result, we observe a homogeneous distribution of surfactant on the droplet's surface and

$Pe=0.01$, the diffusion of the surfactant along the droplet's interface dominates over the surfactant convection. As a result, we observe a homogeneous distribution of surfactant on the droplet's surface and ![]() $\varGamma <1$ over the entire droplet interface for

$\varGamma <1$ over the entire droplet interface for ![]() $\varPi$-thickening and

$\varPi$-thickening and ![]() $\varPi$-thinning surfactant. The lowered surfactant concentration over the droplet's surface also lowers the droplet's

$\varPi$-thinning surfactant. The lowered surfactant concentration over the droplet's surface also lowers the droplet's ![]() $Bq_\mu$ for a

$Bq_\mu$ for a ![]() $\varPi$-thickening surfactant and increases the droplet's

$\varPi$-thickening surfactant and increases the droplet's ![]() $Bq_\mu$ for a

$Bq_\mu$ for a ![]() $\varPi$-thinning surfactant. As a result, the droplet with

$\varPi$-thinning surfactant. As a result, the droplet with ![]() $\varPi$-thinning surfactant breaks at a higher

$\varPi$-thinning surfactant breaks at a higher ![]() $Ca$ than the droplet with

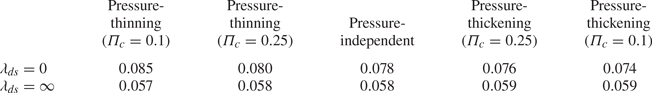

$Ca$ than the droplet with ![]() $\varPi$-thickening surfactant. Tables 2 and 3 compare

$\varPi$-thickening surfactant. Tables 2 and 3 compare ![]() $Ca_C$ of a droplet with a

$Ca_C$ of a droplet with a ![]() $\varPi$-thickening,

$\varPi$-thickening, ![]() $\varPi$-thinning and

$\varPi$-thinning and ![]() $\varPi$-independent surfactant at surface elasticity numbers

$\varPi$-independent surfactant at surface elasticity numbers ![]() $E=0.4$ and

$E=0.4$ and ![]() $E=2$, respectively.

$E=2$, respectively.

Figure 12. Time evolution of a droplet with pressure-dependent interfacial shear viscosity ![]() $Bq_{\mu,{eq}}=2.0$: (a)

$Bq_{\mu,{eq}}=2.0$: (a) ![]() $\varPi _c=0.25$, pressure-thinning; (b)

$\varPi _c=0.25$, pressure-thinning; (b) ![]() $\varPi _c=0.25$, pressure-thickening. The values of dimensionless parameters are:

$\varPi _c=0.25$, pressure-thickening. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.4$,

$E=0.4$, ![]() $\varGamma _\infty =2$,

$\varGamma _\infty =2$, ![]() $Ca = 0.08$ and

$Ca = 0.08$ and ![]() $Pe_s=0.01$.

$Pe_s=0.01$.

Figure 13. Variation of ![]() $Bq_\mu$ and surface concentration

$Bq_\mu$ and surface concentration ![]() $\varGamma$ with the normalized arclength

$\varGamma$ with the normalized arclength ![]() $s$ corresponding to the droplet shapes shown in figure 12 at time

$s$ corresponding to the droplet shapes shown in figure 12 at time ![]() $t = 5.4$.

$t = 5.4$.

Table 2. Values of ![]() $Ca_C$ of a droplet with

$Ca_C$ of a droplet with ![]() $Bq_{eq}=2$,

$Bq_{eq}=2$, ![]() $\lambda =1.0$,

$\lambda =1.0$, ![]() $E=0.4$,

$E=0.4$, ![]() $\varGamma _\infty =2$ and

$\varGamma _\infty =2$ and ![]() $Pe_s=0.01$.

$Pe_s=0.01$.

Table 3. Values of ![]() $Ca_C$ of a droplet with

$Ca_C$ of a droplet with ![]() $Bq_{eq}=2$,

$Bq_{eq}=2$, ![]() $\lambda =1.0$,

$\lambda =1.0$, ![]() $E=2$,

$E=2$, ![]() $\varGamma _\infty =2$ and

$\varGamma _\infty =2$ and ![]() $Pe_s=0.01$.

$Pe_s=0.01$.

Figure 14 shows the evolution of droplet shapes with time for a pressure-thinning surfactant with ![]() $\varPi _c=0.25$ (shown in figure 14a) and a pressure-thickening surfactant with

$\varPi _c=0.25$ (shown in figure 14a) and a pressure-thickening surfactant with ![]() $\varPi _c=0.25$ (shown in figure 14b) at

$\varPi _c=0.25$ (shown in figure 14b) at ![]() $Ca=0.056$, but now the Péclet number is large (

$Ca=0.056$, but now the Péclet number is large (![]() $Pe_s = 10$). Here also we observe that the droplet with

$Pe_s = 10$). Here also we observe that the droplet with ![]() $\varPi$-thinning surfactant attains a stable shape under flow while the droplet with

$\varPi$-thinning surfactant attains a stable shape under flow while the droplet with ![]() $\varPi$-thickening surfactant becomes unstable. Figure 15 shows the variation of

$\varPi$-thickening surfactant becomes unstable. Figure 15 shows the variation of ![]() $Bq_\mu$ and surfactant concentration

$Bq_\mu$ and surfactant concentration ![]() $\varGamma$ with normalized arclength

$\varGamma$ with normalized arclength ![]() $s$ for the droplet shapes shown in figures 14(a) and 14(b) at

$s$ for the droplet shapes shown in figures 14(a) and 14(b) at ![]() $t=8.4$. At

$t=8.4$. At ![]() $Pe_s=10$, we observe that the surfactant gets convected towards the droplet's pole leading to

$Pe_s=10$, we observe that the surfactant gets convected towards the droplet's pole leading to ![]() $\varGamma >1$ in the pole region and

$\varGamma >1$ in the pole region and ![]() $\varGamma <1$ in the equator region. The lowered surfactant concentration in the equator region for a droplet with

$\varGamma <1$ in the equator region. The lowered surfactant concentration in the equator region for a droplet with ![]() $\varPi$-thinning surfactant increases the droplet's

$\varPi$-thinning surfactant increases the droplet's ![]() $Bq_\mu$ and surface shear traction acting on the droplet's equator. For a droplet with only surface shear viscosity, what matters is traction near the droplet's equator and not traction near the droplet's poles, as was discussed for figure 8. As a result, the droplet with pressure-thinning surfactant breaks at a larger

$Bq_\mu$ and surface shear traction acting on the droplet's equator. For a droplet with only surface shear viscosity, what matters is traction near the droplet's equator and not traction near the droplet's poles, as was discussed for figure 8. As a result, the droplet with pressure-thinning surfactant breaks at a larger ![]() $Ca$ than the droplet with pressure-thickening surfactant (

$Ca$ than the droplet with pressure-thickening surfactant (![]() $Ca_C$ of a droplet with pressure-thinning surfactant is 0.056, while

$Ca_C$ of a droplet with pressure-thinning surfactant is 0.056, while ![]() $Ca_C$ of a droplet with pressure-thickening surfactant is 0.054). We observe similar behaviour of pressure-dependent surface viscosity at a higher value of surface elasticity number. At

$Ca_C$ of a droplet with pressure-thickening surfactant is 0.054). We observe similar behaviour of pressure-dependent surface viscosity at a higher value of surface elasticity number. At ![]() $E=2$,

$E=2$, ![]() $Ca_C$ of a droplet with pressure-thinning surfactant is 0.067, while

$Ca_C$ of a droplet with pressure-thinning surfactant is 0.067, while ![]() $Ca_C$ of a droplet with pressure-thickening surfactant is 0.064.

$Ca_C$ of a droplet with pressure-thickening surfactant is 0.064.

Figure 14. Time evolution of a droplet with pressure-dependent interfacial shear viscosity ![]() $Bq_{\mu,{eq}}=2.0$: (a)

$Bq_{\mu,{eq}}=2.0$: (a) ![]() $\varPi _c=0.25$, pressure-thinning; (b)

$\varPi _c=0.25$, pressure-thinning; (b) ![]() $\varPi _c=0.25$, pressure-thickening. The values of dimensionless parameters are:

$\varPi _c=0.25$, pressure-thickening. The values of dimensionless parameters are: ![]() $\lambda =1$,

$\lambda =1$, ![]() $E=0.4$,

$E=0.4$, ![]() $\varGamma _\infty =2$,

$\varGamma _\infty =2$, ![]() $Ca = 0.056$ and

$Ca = 0.056$ and ![]() $Pe_s=10.0$.

$Pe_s=10.0$.

Figure 15. Variation of ![]() $Bq_\mu$ and surface concentration

$Bq_\mu$ and surface concentration ![]() $\varGamma$ with the normalized arclength

$\varGamma$ with the normalized arclength ![]() $s$ corresponding to the droplet shapes shown in figure 14 at time