1. Introduction

The rheology of a suspension of rigid particles in a Newtonian fluid has been well studied analytically (Einstein Reference Einstein1906; Batchelor & Green Reference Batchelor and Green1972; Brenner Reference Brenner1974; Dabade, Marath & Subramanian Reference Dabade, Marath and Subramanian2016), experimentally (Krieger Reference Krieger1972; de Kruif et al. Reference de Kruif, van Iersel, Vrij and Russel1985; Van der Werff & De Kruif Reference Van der Werff and De Kruif1989; Zarraga, Hill & Leighton Reference Zarraga, Hill and Leighton2000; Singh & Nott Reference Singh and Nott2003; Snook et al. Reference Snook, Davidson, Butler, Pouliquen and Guazzelli2014) and computationally (Bossis & Brady Reference Bossis and Brady1984; Ladd Reference Ladd1994; Singh & Nott Reference Singh and Nott2000; Gallier et al. Reference Gallier, Lemaire, Lobry and Peters2014; Butler & Snook Reference Butler and Snook2018). However, there are many examples of suspensions in nature and in industrial settings wherein the suspended particles are deformable, in the form of fluid droplets, vesicles, capsules or elastic particles; blood is an example of such a suspension, comprising cells of a range of deformability. In these cases, an imposed shear flow causes the particles to change shape, and determination of their evolving shapes is central to determining the rheology of the suspension. Even for suspensions that are dilute enough that interaction between particles may be ignored, the rheology is non-Newtonian due to the deformation of an isolated particle caused by the imposed flow. The shape dynamics of fluid droplets and its influence on the suspension rheology has been studied for several decades (Oldroyd Reference Oldroyd1953; Cox Reference Cox1969; Stone Reference Stone1994; Wetzel & Tucker Reference Wetzel and Tucker2001; Jackson & Tucker Reference Jackson and Tucker2003; Minale Reference Minale2010; Mwasame, Wagner & Beris Reference Mwasame, Wagner and Beris2017). In recent years, more attention has been devoted to the dynamics of vesicles and capsules (Kraus et al. Reference Kraus, Wintz, Seifert and Lipowsky1996; Rioual, Biben & Misbah Reference Rioual, Biben and Misbah2004; Kantsler & Steinberg Reference Kantsler and Steinberg2006; Misbah Reference Misbah2006; Danker et al. Reference Danker, Biben, Podgorski, Verdier and Misbah2007; Danker & Misbah Reference Danker and Misbah2007; Noguchi & Gompper Reference Noguchi and Gompper2007; Zhao & Shaqfeh Reference Zhao and Shaqfeh2011; Guedda, Benlahsen & Misbah Reference Guedda, Benlahsen and Misbah2014).

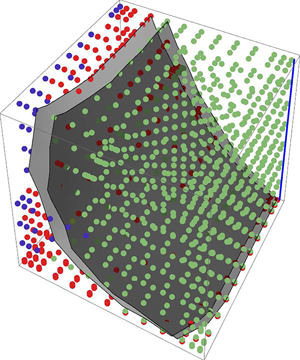

Most of the studies on deformable elastic and viscoelastic particles are restricted to the small deformation regime, wherein the constitutive relation for the elastic stress is effectively linear (Fröhlich & Sack Reference Fröhlich and Sack1946; Cerf Reference Cerf1952; Goddard & Miller Reference Goddard and Miller1967). The first systematic investigation of finite and large deformation of viscoelastic particles suspended in a Newtonian fluid was presented by Roscoe (Reference Roscoe1967), who used the neo-Hookean and Mooney–Rivlin constitutive models for the elastic stress. Roscoe's study was confined to the steady conformation (shape and orientation) of particles that are initially spherical (i.e. before shear is commenced). With the assumption that the particle undergoes homogeneous deformation in an ambient linear flow (where the undisturbed strain rate ![]() $\dot {\gamma }$ is a constant), Roscoe deduced that the particle traverses a sequence of ellipsoidal shapes with changing aspect ratios and orientation, as shown in figure 1, until a steady conformation is reached. At steady state, material points within the ellipsoidal particle execute a ‘tank-treading’ motion. Making use of Jeffery's result for the fluid velocity field around a rigid ellipsoid (Jeffery Reference Jeffery1922) and imposing continuity of traction at the particle surface, the particle shape and its contribution to the suspension stress were determined in terms of the elastic capillary number

$\dot {\gamma }$ is a constant), Roscoe deduced that the particle traverses a sequence of ellipsoidal shapes with changing aspect ratios and orientation, as shown in figure 1, until a steady conformation is reached. At steady state, material points within the ellipsoidal particle execute a ‘tank-treading’ motion. Making use of Jeffery's result for the fluid velocity field around a rigid ellipsoid (Jeffery Reference Jeffery1922) and imposing continuity of traction at the particle surface, the particle shape and its contribution to the suspension stress were determined in terms of the elastic capillary number ![]() $G \equiv \mu \dot {\gamma }/\eta$, where

$G \equiv \mu \dot {\gamma }/\eta$, where ![]() $\mu$ and

$\mu$ and ![]() $\eta$ are the viscosity of the suspending fluid and the elastic shear modulus of the particle, respectively. The existence of the tank-treading steady state was numerically verified in two (circles; see Gao & Hu Reference Gao and Hu2009) and three dimensions (spheres; see Gao, Hu & Castañeda Reference Gao, Hu and Castañeda2011), thereby validating the assumption of homogeneous deformation by Roscoe (Reference Roscoe1967).

$\eta$ are the viscosity of the suspending fluid and the elastic shear modulus of the particle, respectively. The existence of the tank-treading steady state was numerically verified in two (circles; see Gao & Hu Reference Gao and Hu2009) and three dimensions (spheres; see Gao, Hu & Castañeda Reference Gao, Hu and Castañeda2011), thereby validating the assumption of homogeneous deformation by Roscoe (Reference Roscoe1967).

Figure 1. Soft elastic particle deforming through a series of ellipsoidal shapes due to applied shear. The intensity of colour indicates the magnitude of the stress along the major axis of the ellipsoid.

Gao et al. (Reference Gao, Hu and Castañeda2011) developed a semi-analytical method for determining the shape dynamics of elastic ellipsoids obeying the neo-Hookean constitutive relation, but restricted attention to initially spherical particles. The analysis was extended to prolate spheroids whose symmetry axis is in the plane of shear by Gao, Hu & Castaneda (Reference Gao, Hu and Castaneda2012). Using the stress polarization technique introduced by Eshelby (Reference Eshelby1957, Reference Eshelby1959) for an elastic inclusion in an elastic matrix, the authors related the time derivative of the stress to the strain rate and vorticity fields inside the elastic particle through fourth-order shape tensors. The method yields a set of coupled nonlinear ordinary differential equations for the aspect ratios, orientation and the (three) stress components, which was solved numerically to obtain the transient response. An important aspect of this study is that, in addition to the tumbling motion expected in the near-rigid (small ![]() $G$) limit, the authors showed the presence of a novel trembling motion that had earlier been observed in vesicles (Kantsler & Steinberg Reference Kantsler and Steinberg2006; Misbah Reference Misbah2006; Zhao & Shaqfeh Reference Zhao and Shaqfeh2011) and further, determined the tumbling–trembling phase diagram in the

$G$) limit, the authors showed the presence of a novel trembling motion that had earlier been observed in vesicles (Kantsler & Steinberg Reference Kantsler and Steinberg2006; Misbah Reference Misbah2006; Zhao & Shaqfeh Reference Zhao and Shaqfeh2011) and further, determined the tumbling–trembling phase diagram in the ![]() $G$–

$G$–![]() $\omega _{0}$ plane.

$\omega _{0}$ plane.

A key step in the method of Gao et al. (Reference Gao, Hu and Castañeda2011, Reference Gao, Hu and Castaneda2012) is to obtain a relation between the time derivative of the stress and the strain rate by taking the upper convected time derivative of the neo-Hookean constitutive relation. However, for more general constitutive relations, such as Mooney–Rivlin, the time derivative of the stress cannot be related to the strain rate alone – the strain too will appear in the relation, thereby precluding the use of this method. It is therefore more appropriate to take the conventional approach in elasticity, where the stress is related to the strain or deformation. We show that the deformation at each instant of time can be obtained by recognizing that Roscoe's method (Roscoe Reference Roscoe1967) for determining the stress in the fluid can be extended to dynamically evolving states; enforcing continuity of the traction at the particle surface gives relations for the strain rate and vorticity within the particle, which in turn are related to the time evolution of the shape and orientation. Importantly, this method provides physical insight into the nature of the shape dynamics. For instance, we see that the rate of change of orientation of the particle has two contributions, one due to vorticity-induced rotation and the other to stretching of the particle along a direction different from its principal axes. For simple shear flow, these two components are of opposite sign for a range of orientations, and their relative magnitudes decide whether a tumbling or trembling dynamics occurs; a steady state can be attained only when the two contributions are precisely balanced. Although we restrict our attention to the in-plane dynamics for the case of simple shear flow, wherein two principal axes of the spheroid are in the plane of shear, our approach is general enough that the dynamics resulting from arbitrary initial orientations can be obtained; the latter will be considered in a subsequent paper.

The following caveat must be made with regard to the solutions we obtain by assuming the particle to be ellipsoidal at all times (equivalently, assuming the stress and deformation in the particle to be always uniform). Eshelby (Reference Eshelby1957, Reference Eshelby1959) showed that the ellipsoidal shape is the only solution for a linear elastic inclusion in a linear elastic medium; this was later extended to Newtonian drops in a Newtonian fluid by Wetzel & Tucker (Reference Wetzel and Tucker2001). In both cases, the constitutive relations for the dispersed and continuous phases are linear. When the inclusion is a nonlinear elastic solid, it is not known a priori that the shape will be ellipsoidal. The only assertion we can make is that the assumption of ellipsoidal shape yields a solution – however, this need not be the only solution. Nevertheless, the numerical validation of Gao & Hu (Reference Gao and Hu2009); Gao et al. (Reference Gao, Hu and Castañeda2011) is an indication that the solutions are physically relevant ones.

The paper is organized as follows. In § 2, we present our method for determining the shape dynamics of an isolated ellipsoidal particle suspended in a Newtonian fluid whose undisturbed flow is simple shear. The governing equations are then specialized for the in-plane dynamics of elastic and viscoelastic particles. In § 3, we solve the governing equations, where we first show that the results of Gao et al. (Reference Gao, Hu and Castaneda2012) for elastic spheres and prolate spheroids are recovered by our method (Appendix C). We then obtain the in-plane dynamics of elastic particles that are initially oblate spheroids or triaxial ellipsoids and construct the respective phase diagrams of dynamical states in the ![]() $G$–aspect ratio space. The effect of viscoelasticity on the shape dynamics is then discussed. We conclude in § 4 with a summary of our main findings, the inferences drawn from them, and the potential applications of our study.

$G$–aspect ratio space. The effect of viscoelasticity on the shape dynamics is then discussed. We conclude in § 4 with a summary of our main findings, the inferences drawn from them, and the potential applications of our study.

2. Mathematical formulation

In this section, we derive the equations that govern the dynamics of the particle shape, orientation and stress. Our interest is in the dynamics of a dilute suspension of small particles of nominal size ![]() $\ell _p$ dispersed in viscous Newtonian liquids of density

$\ell _p$ dispersed in viscous Newtonian liquids of density ![]() $\rho$ and viscosity

$\rho$ and viscosity ![]() $\mu$, with the suspension subjected to a uniform macroscopic strain rate. The bulk properties of such a suspension may be determined from the analysis of a single particle suspended in the fluid subjected to an undisturbed uniform strain rate of magnitude

$\mu$, with the suspension subjected to a uniform macroscopic strain rate. The bulk properties of such a suspension may be determined from the analysis of a single particle suspended in the fluid subjected to an undisturbed uniform strain rate of magnitude ![]() $\dot \gamma$. We further restrict attention to the flow regime where the Reynolds number

$\dot \gamma$. We further restrict attention to the flow regime where the Reynolds number ![]() $Re \equiv \rho \dot {\gamma }^2 \ell _p^2/\mu$ is negligibly small. Therefore, we may ignore the effects of inertia and solve the quasistatic equations of motion in the fluid and the elastic particle.

$Re \equiv \rho \dot {\gamma }^2 \ell _p^2/\mu$ is negligibly small. Therefore, we may ignore the effects of inertia and solve the quasistatic equations of motion in the fluid and the elastic particle.

Roscoe (Reference Roscoe1967) considered the steady shape and orientation of elastic and viscoelastic particles whose stress-free shape is a sphere. When the undisturbed strain rate in the fluid is spatially uniform, he hypothesized that the particle would approach the steady state by traversing a series of ellipsoidal shapes wherein the strain rate in the particle is uniform at every instant. At steady state, every material point must be in continuous motion along a closed elliptical path, i.e. the deformed particle executes a ‘tank-treading’ motion. We wish to determine the transient and unsteady dynamics of initially stress-free ellipsoidal particles, for which Roscoe's analysis is not directly applicable. However, an aspect of Roscoe's analysis, namely the determination of the fluid stress for a given shape and orientation of the ellipsoid, may be easily extended for dynamical states. We describe this aspect of Roscoe's analysis in § 2.1 and its extension to dynamical states in § 2.2. By enforcing continuity of traction on the particle surface, we relate the strain rate and vorticity in the particle to the stress at a given instant of time in § 2.2, and from them obtain relations for the shape dynamics in § 2.3. We then obtain the stress in the particle in terms of the incremental change in shape from the previous time instant in § 2.4, thereby closing the problem. The method described in this section for determining the shape dynamics is applicable for arbitrary linear velocity fields ![]() ${\boldsymbol {u}}^\infty$, but we consider only simple shear flow in this paper.

${\boldsymbol {u}}^\infty$, but we consider only simple shear flow in this paper.

2.1. Stress in the fluid

Consider a neutrally buoyant deformable ellipsoidal particle suspended in an unbounded Newtonian fluid subjected to a uniform undisturbed velocity gradient ![]() ${\boldsymbol{L}}^\infty \equiv {\boldsymbol {\nabla u^\infty }}$. In the fixed laboratory Cartesian coordinate frame (figure 2), the only non-zero component of

${\boldsymbol{L}}^\infty \equiv {\boldsymbol {\nabla u^\infty }}$. In the fixed laboratory Cartesian coordinate frame (figure 2), the only non-zero component of ![]() ${\boldsymbol{L}}^\infty$ for simple shear is

${\boldsymbol{L}}^\infty$ for simple shear is ![]() ${\mathsf{L}}^\infty _{12} = \dot \gamma$. We restrict attention to initial orientations where two principal axes of the ellipsoid are in the 1–2 plane; for spheroids one of them is the symmetry axis. From considerations of symmetry, these two principal axes will always remain in the 1–2 plane. However, our method is general and may also be used for the out-of-plane dynamics arising from the initial orientation not being in the 1–2 plane.

${\mathsf{L}}^\infty _{12} = \dot \gamma$. We restrict attention to initial orientations where two principal axes of the ellipsoid are in the 1–2 plane; for spheroids one of them is the symmetry axis. From considerations of symmetry, these two principal axes will always remain in the 1–2 plane. However, our method is general and may also be used for the out-of-plane dynamics arising from the initial orientation not being in the 1–2 plane.

Figure 2. Schematic depicting the semi-axis lengths and orientations of the principal axes of a particle whose initial (stress free) shape is (a) an oblate spheroid and (b) prolate spheroid or triaxial ellipsoid. The axes labelled (![]() $1,2,x_3$) are the coordinate axes in the fixed laboratory reference frame, and (

$1,2,x_3$) are the coordinate axes in the fixed laboratory reference frame, and (![]() $x_1,x_2,x_3$) are the principal axes of the particle. The aspect ratios of the particle are defined as

$x_1,x_2,x_3$) are the principal axes of the particle. The aspect ratios of the particle are defined as ![]() $\omega _1 = \alpha _2/\alpha _1$,

$\omega _1 = \alpha _2/\alpha _1$, ![]() $\omega _2 = \alpha _3/\alpha _1$, where the

$\omega _2 = \alpha _3/\alpha _1$, where the ![]() $\alpha _i$ are the lengths of the principal semi-axes.

$\alpha _i$ are the lengths of the principal semi-axes.

Hereafter, all the quantities of interest are quoted or reported in dimensionless form (unless specifically stated otherwise): the strain rate and vorticity are scaled by ![]() $\dot \gamma$, time by

$\dot \gamma$, time by ![]() $\dot \gamma ^{-1}$ and stress (in the fluid and particle) by

$\dot \gamma ^{-1}$ and stress (in the fluid and particle) by ![]() $\mu \dot \gamma$. Let

$\mu \dot \gamma$. Let ![]() ${\boldsymbol{D}}^\infty$ and

${\boldsymbol{D}}^\infty$ and ![]() ${\boldsymbol{W}}^\infty$ denote the undisturbed strain rate and vorticity tensors, respectively. As argued by Roscoe (Reference Roscoe1967) (and validated numerically by Gao et al. Reference Gao, Hu and Castañeda2011), the strain rate

${\boldsymbol{W}}^\infty$ denote the undisturbed strain rate and vorticity tensors, respectively. As argued by Roscoe (Reference Roscoe1967) (and validated numerically by Gao et al. Reference Gao, Hu and Castañeda2011), the strain rate ![]() $\boldsymbol{\mathsf{D}}$ and vorticity

$\boldsymbol{\mathsf{D}}$ and vorticity ![]() $\boldsymbol{\mathsf{W}}$ in the particle vary in time but are spatially uniform. To determine the velocity and stress fields in the fluid, we follow Roscoe (Reference Roscoe1967) by subtracting

$\boldsymbol{\mathsf{W}}$ in the particle vary in time but are spatially uniform. To determine the velocity and stress fields in the fluid, we follow Roscoe (Reference Roscoe1967) by subtracting ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\boldsymbol{\mathsf{W}}$, respectively, from the strain rate and vorticity at every point in the domain. As a result, the strain and vorticity fields now correspond to a rigid, non-rotating ellipsoid in a fluid of undisturbed strain rate

$\boldsymbol{\mathsf{W}}$, respectively, from the strain rate and vorticity at every point in the domain. As a result, the strain and vorticity fields now correspond to a rigid, non-rotating ellipsoid in a fluid of undisturbed strain rate ![]() $\boldsymbol{\mathsf{D}}' \equiv {\boldsymbol{D}}^\infty - \boldsymbol{\mathsf{D}}$ and vorticity

$\boldsymbol{\mathsf{D}}' \equiv {\boldsymbol{D}}^\infty - \boldsymbol{\mathsf{D}}$ and vorticity ![]() $\boldsymbol{\mathsf{W}}' \equiv {\boldsymbol{W}}^\infty - \boldsymbol{\mathsf{W}}$. It follows from the linearity of Stokes equations that the velocity and stress fields in the fluid due to the deformable particle may be obtained by adding to the respective fields obtained for the above rigid particle problem, the contributions from the uniform strain rate and vorticity

$\boldsymbol{\mathsf{W}}' \equiv {\boldsymbol{W}}^\infty - \boldsymbol{\mathsf{W}}$. It follows from the linearity of Stokes equations that the velocity and stress fields in the fluid due to the deformable particle may be obtained by adding to the respective fields obtained for the above rigid particle problem, the contributions from the uniform strain rate and vorticity ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\boldsymbol{\mathsf{W}}$. As a result, the stress field in the fluid is

$\boldsymbol{\mathsf{W}}$. As a result, the stress field in the fluid is

where ![]() ${\boldsymbol{\mathsf{T}}}'$ is the stress field around a rigid, non-rotating ellipsoid in a fluid of undisturbed strain rate and vorticity

${\boldsymbol{\mathsf{T}}}'$ is the stress field around a rigid, non-rotating ellipsoid in a fluid of undisturbed strain rate and vorticity ![]() $\boldsymbol{\mathsf{D}}'$ and

$\boldsymbol{\mathsf{D}}'$ and ![]() $\boldsymbol{\mathsf{W}}'$, respectively. The expression for

$\boldsymbol{\mathsf{W}}'$, respectively. The expression for ![]() ${\boldsymbol{\mathsf{T}}}'$ was given by Jeffery (Reference Jeffery1922), who studied the motion of rigid ellipsoidal particles in a Newtonian fluid subjected to homogeneous linear flow. Jeffery's expression was written compactly (with some errors in transcription corrected) by Roscoe (Reference Roscoe1967) as

${\boldsymbol{\mathsf{T}}}'$ was given by Jeffery (Reference Jeffery1922), who studied the motion of rigid ellipsoidal particles in a Newtonian fluid subjected to homogeneous linear flow. Jeffery's expression was written compactly (with some errors in transcription corrected) by Roscoe (Reference Roscoe1967) as ![]() ${\boldsymbol{\mathsf{T}}}' = -p' {\boldsymbol{\mathsf{I}}} + \boldsymbol{\mathsf{A}}'$, where

${\boldsymbol{\mathsf{T}}}' = -p' {\boldsymbol{\mathsf{I}}} + \boldsymbol{\mathsf{A}}'$, where ![]() $p'$ is an arbitrary hydrostatic pressure and

$p'$ is an arbitrary hydrostatic pressure and ![]() $\boldsymbol{\mathsf{A}}'$ depends on the shape and orientation of the ellipsoid and linearly on

$\boldsymbol{\mathsf{A}}'$ depends on the shape and orientation of the ellipsoid and linearly on ![]() $\boldsymbol{\mathsf{D}}'$. Note that

$\boldsymbol{\mathsf{D}}'$. Note that ![]() $\boldsymbol{\mathsf{A}}'$ is not necessarily traceless. The arguments leading to (2.1) ensure continuity of velocity on the particle surface.

$\boldsymbol{\mathsf{A}}'$ is not necessarily traceless. The arguments leading to (2.1) ensure continuity of velocity on the particle surface.

It is convenient to use a coordinate frame that is instantaneously aligned with the principal axes of the ellipsoid (see figure 2), in which the equation of the surface is

where ![]() $\alpha _i$ are the lengths of the three principal semi-axes. The axis labels are chosen based on the initial shape: for oblate spheroids, the

$\alpha _i$ are the lengths of the three principal semi-axes. The axis labels are chosen based on the initial shape: for oblate spheroids, the ![]() $x_1$ axis is the in-plane principal axis of smaller length. For prolate spheroids and triaxial ellipsoids, the

$x_1$ axis is the in-plane principal axis of smaller length. For prolate spheroids and triaxial ellipsoids, the ![]() $x_1$ axis is the in-plane principal axis of larger length. Thus, the

$x_1$ axis is the in-plane principal axis of larger length. Thus, the ![]() $x_1$ axis for spheroids in the stress-free state coincides with the symmetry axis. The aspect ratios are defined as

$x_1$ axis for spheroids in the stress-free state coincides with the symmetry axis. The aspect ratios are defined as ![]() $\omega _1 = \alpha _2/\alpha _1$ and

$\omega _1 = \alpha _2/\alpha _1$ and ![]() $\omega _2 = \alpha _3/\alpha _1$.

$\omega _2 = \alpha _3/\alpha _1$.

In the particle coordinate frame, the undisturbed strain rate and vorticity may be expressed in terms of the Euler angles measuring the orientation of the principal axes relative to the axes of the fixed laboratory frame. For the in-plane dynamics in simple shear, only the Euler angle in the plane of shear varies with time (the other two being zero) and the undisturbed strain rate and vorticity are

\begin{equation}

{\boldsymbol{D}}^\infty = \begin{bmatrix}

\frac{1}{2}\sin 2\theta & \frac{1}{2}\cos 2\theta & 0 \\

\frac{1}{2}\cos 2\theta & \frac{-1}{2}\sin 2\theta & 0 \\ 0

& 0 & 0 \end{bmatrix}, \quad

{\boldsymbol{W}}^\infty = \begin{bmatrix} 0 &

\frac{1}{2} & 0 \\ \frac{-1}{2} & 0 & 0 \\ 0 & 0 & 0

\end{bmatrix}, \end{equation}

\begin{equation}

{\boldsymbol{D}}^\infty = \begin{bmatrix}

\frac{1}{2}\sin 2\theta & \frac{1}{2}\cos 2\theta & 0 \\

\frac{1}{2}\cos 2\theta & \frac{-1}{2}\sin 2\theta & 0 \\ 0

& 0 & 0 \end{bmatrix}, \quad

{\boldsymbol{W}}^\infty = \begin{bmatrix} 0 &

\frac{1}{2} & 0 \\ \frac{-1}{2} & 0 & 0 \\ 0 & 0 & 0

\end{bmatrix}, \end{equation}

where ![]() $\theta$ is the angle subtended by the

$\theta$ is the angle subtended by the ![]() $x_1$ axis with the flow direction in the anti-clockwise direction (figure 2).

$x_1$ axis with the flow direction in the anti-clockwise direction (figure 2).

2.2. Strain rate and vorticity in the particle

To proceed further, we enforce continuity of traction at the particle surface

where ![]() ${{\boldsymbol{\sigma} }}^p$ is the (spatially uniform) stress in the particle and

${{\boldsymbol{\sigma} }}^p$ is the (spatially uniform) stress in the particle and ![]() ${\boldsymbol {n}}$ is a unit vector normal to the surface. As

${\boldsymbol {n}}$ is a unit vector normal to the surface. As ![]() ${{\boldsymbol{\sigma} }}^p$ is uniform, it suffices to enforce continuity of traction at the intersection of the ellipsoidal surface with each principal axis. From (2.1) and (2.4), continuity of the normal component of the traction

${{\boldsymbol{\sigma} }}^p$ is uniform, it suffices to enforce continuity of traction at the intersection of the ellipsoidal surface with each principal axis. From (2.1) and (2.4), continuity of the normal component of the traction ![]() ${\boldsymbol {n}} \boldsymbol{\cdot} {{\boldsymbol{\sigma} }} \boldsymbol{\cdot} {\boldsymbol {n}}$ at the intersection with the

${\boldsymbol {n}} \boldsymbol{\cdot} {{\boldsymbol{\sigma} }} \boldsymbol{\cdot} {\boldsymbol {n}}$ at the intersection with the ![]() $i$ axis gives

$i$ axis gives

where ![]() $\hat {A}'_{ij}$ is the value of

$\hat {A}'_{ij}$ is the value of ![]() $A'_{ij}$ at

$A'_{ij}$ at ![]() $x_i = \alpha _i$,

$x_i = \alpha _i$, ![]() $x_k = 0$ (

$x_k = 0$ (![]() $k \ne i$). The pressures

$k \ne i$). The pressures ![]() $p'$ in the fluid and

$p'$ in the fluid and ![]() $p$ in the particle (see (2.18)) may be eliminated by taking differences between the normal traction at the intersections of the principal axes with the surface of the ellipsoid,

$p$ in the particle (see (2.18)) may be eliminated by taking differences between the normal traction at the intersections of the principal axes with the surface of the ellipsoid,

The expression for ![]() $\hat {{\mathsf{A}}}'_{11}$ is (Roscoe Reference Roscoe1967)

$\hat {{\mathsf{A}}}'_{11}$ is (Roscoe Reference Roscoe1967)

The expressions for ![]() $\hat {{\mathsf{A}}}'_{22}$ and

$\hat {{\mathsf{A}}}'_{22}$ and ![]() $\hat {{\mathsf{A}}}'_{33}$ are obtained by cyclic permutation of indices in (2.7). Here,

$\hat {{\mathsf{A}}}'_{33}$ are obtained by cyclic permutation of indices in (2.7). Here, ![]() $g''_i$ are functions of the semi-axis lengths

$g''_i$ are functions of the semi-axis lengths ![]() $\alpha _i$ defined by Roscoe (Reference Roscoe1967); they are reproduced in Appendix A for the convenience of the reader. For the state of steady orientation and shape, the terms

$\alpha _i$ defined by Roscoe (Reference Roscoe1967); they are reproduced in Appendix A for the convenience of the reader. For the state of steady orientation and shape, the terms ![]() ${\mathsf{D}}_{ii}$ in (2.5)–(2.7) should be set to zero (see (2.16)); this was the state considered by Roscoe. As we wish to determine the transient and unsteady dynamics, we must retain these terms.

${\mathsf{D}}_{ii}$ in (2.5)–(2.7) should be set to zero (see (2.16)); this was the state considered by Roscoe. As we wish to determine the transient and unsteady dynamics, we must retain these terms.

Substituting the expressions for ![]() $\hat {{\mathsf{A}}}'_{ii}$ in (2.6) and rearranging the terms, we get

$\hat {{\mathsf{A}}}'_{ii}$ in (2.6) and rearranging the terms, we get

\begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}+{\boldsymbol{\mathsf{\sigma}}}^p_{22}-2{\boldsymbol{\mathsf{\sigma}}}^p_{33} &= 5(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right) \nonumber\\ &\quad + 2 \left(I_{23} - J_{23}\right)\left(\left(D^{\infty}_{11}-D_{11}\right)+\left(D^{\infty}_{22}-D_{22}\right)\right)) \nonumber\\&\quad + 6 \left(D_{11}-D_{22}\right), \end{align}

\begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}+{\boldsymbol{\mathsf{\sigma}}}^p_{22}-2{\boldsymbol{\mathsf{\sigma}}}^p_{33} &= 5(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right) \nonumber\\ &\quad + 2 \left(I_{23} - J_{23}\right)\left(\left(D^{\infty}_{11}-D_{11}\right)+\left(D^{\infty}_{22}-D_{22}\right)\right)) \nonumber\\&\quad + 6 \left(D_{11}-D_{22}\right), \end{align}where,

and ![]() $g=g''_{2}g''_{3}+g''_{3}g''_{1}+g''_{1}g''_{2}$. Explicit expressions for

$g=g''_{2}g''_{3}+g''_{3}g''_{1}+g''_{1}g''_{2}$. Explicit expressions for ![]() $D_{11}$ and

$D_{11}$ and ![]() $D_{22}$ are obtained by solving (2.8a,b) and are provided in Appendix B.

$D_{22}$ are obtained by solving (2.8a,b) and are provided in Appendix B.

Continuity of the tangential component of the traction ![]() ${\boldsymbol {t}} \boldsymbol{\cdot} {{\boldsymbol{\sigma} }} \boldsymbol{\cdot} {\boldsymbol {n}}$, where

${\boldsymbol {t}} \boldsymbol{\cdot} {{\boldsymbol{\sigma} }} \boldsymbol{\cdot} {\boldsymbol {n}}$, where ![]() ${\boldsymbol {t}}$ is a unit tangent on the 1-axis, gives

${\boldsymbol {t}}$ is a unit tangent on the 1-axis, gives

where

The factors ![]() $g_i$ and

$g_i$ and ![]() $g'_i$ are functions of the semi-axis lengths

$g'_i$ are functions of the semi-axis lengths ![]() $\alpha _i$ (Roscoe Reference Roscoe1967) and are defined in Appendix A. Similarly,

$\alpha _i$ (Roscoe Reference Roscoe1967) and are defined in Appendix A. Similarly, ![]() $\hat {{\mathsf{A}}}'_{21}$ can be obtained by interchanging the indices 1 and 2 in (2.11). Symmetry of

$\hat {{\mathsf{A}}}'_{21}$ can be obtained by interchanging the indices 1 and 2 in (2.11). Symmetry of ![]() ${{\boldsymbol{\sigma} }}^p$ requires that

${{\boldsymbol{\sigma} }}^p$ requires that ![]() $\hat {{\mathsf{A}}}'_{12}=\hat {{\mathsf{A}}}'_{21}$, which yields the relation

$\hat {{\mathsf{A}}}'_{12}=\hat {{\mathsf{A}}}'_{21}$, which yields the relation

Noting that ![]() $g_1-g_2 = (\alpha _{1}^{2} - \alpha _{2}^{2})g'_3$, (2.12) results in the following relation between the strain rate and the vorticity fields inside the particle:

$g_1-g_2 = (\alpha _{1}^{2} - \alpha _{2}^{2})g'_3$, (2.12) results in the following relation between the strain rate and the vorticity fields inside the particle:

Substituting (2.13) into the expression for ![]() $\hat {{\mathsf{A}}}'_{12}$ and subsequently into (2.10) yields the expression for the shear stress in the 1–2 plane

$\hat {{\mathsf{A}}}'_{12}$ and subsequently into (2.10) yields the expression for the shear stress in the 1–2 plane

\begin{equation} {\boldsymbol{\mathsf{\sigma}}}^p_{12}=\frac{8\left[g_1 + \alpha_{2}^{2} g'_3 \left(\dfrac{\alpha_{1}^2 - \alpha_{2}^2}{\alpha_{1}^2 + \alpha_{2}^2} \right) \right] (D^{\infty}_{12}-D_{12}) }{2g'_3(\alpha_{1}^{2}g_1 + \alpha_{2}^{2} g_2)} + 2 D_{12}. \end{equation}

\begin{equation} {\boldsymbol{\mathsf{\sigma}}}^p_{12}=\frac{8\left[g_1 + \alpha_{2}^{2} g'_3 \left(\dfrac{\alpha_{1}^2 - \alpha_{2}^2}{\alpha_{1}^2 + \alpha_{2}^2} \right) \right] (D^{\infty}_{12}-D_{12}) }{2g'_3(\alpha_{1}^{2}g_1 + \alpha_{2}^{2} g_2)} + 2 D_{12}. \end{equation}

Expressions for ![]() ${\boldsymbol{\mathsf{\sigma}}} ^p_{23}$ and

${\boldsymbol{\mathsf{\sigma}}} ^p_{23}$ and ![]() ${\boldsymbol{\mathsf{\sigma}}} ^p_{13}$ (needed only for the off-plane dynamics) may be obtained by cyclic permutation of indices in (2.14). Equations (2.13) and (2.14) provide the required relations for

${\boldsymbol{\mathsf{\sigma}}} ^p_{13}$ (needed only for the off-plane dynamics) may be obtained by cyclic permutation of indices in (2.14). Equations (2.13) and (2.14) provide the required relations for ![]() $D_{12}$ and

$D_{12}$ and ![]() $W_{12}$; the expressions are lengthy and given in Appendix B.

$W_{12}$; the expressions are lengthy and given in Appendix B.

Thus, with knowledge of the particle stress ![]() ${{\boldsymbol{\sigma} }}^p$, we can determine

${{\boldsymbol{\sigma} }}^p$, we can determine ![]() $\boldsymbol{\mathsf{D}}$ and

$\boldsymbol{\mathsf{D}}$ and ![]() $\boldsymbol{\mathsf{W}}$ in the particle. The determination of

$\boldsymbol{\mathsf{W}}$ in the particle. The determination of ![]() ${{\boldsymbol{\sigma} }}^p$ from the instantaneous orientation and shape of the particle, starting from the stress-free configuration at

${{\boldsymbol{\sigma} }}^p$ from the instantaneous orientation and shape of the particle, starting from the stress-free configuration at ![]() $t = 0$, is discussed in § 2.4.

$t = 0$, is discussed in § 2.4.

2.3. Evolution of particle shape and orientation

The evolution of the shape and orientation can be obtained in terms of the strain rate and vorticity in the particle using the formulation of Wetzel & Tucker (Reference Wetzel and Tucker2001). In the coordinate system instantaneously aligned with the particle principal axes at time ![]() $t$ (but not co-rotating with it), the surface of the ellipsoid satisfies the equation

$t$ (but not co-rotating with it), the surface of the ellipsoid satisfies the equation ![]() ${\boldsymbol{S}} {\boldsymbol {:}} {\boldsymbol {x x}} = 1$, where

${\boldsymbol{S}} {\boldsymbol {:}} {\boldsymbol {x x}} = 1$, where ![]() ${\boldsymbol{S}}$ is the diagonal shape tensor with components

${\boldsymbol{S}}$ is the diagonal shape tensor with components ![]() ${\mathsf{S}}_{ii}=1/\alpha _i^2$. Applying the material derivative to this equation and using the definition of the instantaneous velocity field inside the particle,

${\mathsf{S}}_{ii}=1/\alpha _i^2$. Applying the material derivative to this equation and using the definition of the instantaneous velocity field inside the particle, ![]() ${\boldsymbol {v}}= {\boldsymbol{L}} \boldsymbol{\cdot} {\boldsymbol {x}}$, where

${\boldsymbol {v}}= {\boldsymbol{L}} \boldsymbol{\cdot} {\boldsymbol {x}}$, where ![]() ${\boldsymbol{L}}$ is the uniform velocity gradient in the particle, the following relation can be obtained:

${\boldsymbol{L}}$ is the uniform velocity gradient in the particle, the following relation can be obtained:

Note that ![]() ${\mathrm d}{\boldsymbol{S}}/{\mathrm d} t$ is not diagonal, as a result of particle rotation; it is obtained by replacing

${\mathrm d}{\boldsymbol{S}}/{\mathrm d} t$ is not diagonal, as a result of particle rotation; it is obtained by replacing ![]() ${\boldsymbol{S}}$ by

${\boldsymbol{S}}$ by ![]() ${\boldsymbol{S}}' = {\boldsymbol{\mathsf{R}}}(\theta ) \boldsymbol{\cdot} {\boldsymbol{S}} \boldsymbol{\cdot} {\boldsymbol{\mathsf{R}}}^{{\rm T}}(\theta )$, where

${\boldsymbol{S}}' = {\boldsymbol{\mathsf{R}}}(\theta ) \boldsymbol{\cdot} {\boldsymbol{S}} \boldsymbol{\cdot} {\boldsymbol{\mathsf{R}}}^{{\rm T}}(\theta )$, where ![]() ${\boldsymbol{\mathsf{R}}}(\theta )$ is the rotation tensor corresponding to a rotation by angle

${\boldsymbol{\mathsf{R}}}(\theta )$ is the rotation tensor corresponding to a rotation by angle ![]() $\theta$ in the 1–2 plane, taking the time derivative of

$\theta$ in the 1–2 plane, taking the time derivative of ![]() ${\boldsymbol{S}}'$, and then setting

${\boldsymbol{S}}'$, and then setting ![]() $\theta$ to zero. Equation (2.15) is the only aspect of the analysis of Wetzel & Tucker (Reference Wetzel and Tucker2001) that we use. In particular, we eschew using their method of writing the deformation rate and vorticity in the particle in terms of fourth rank ‘concentration tensors’, and use instead the more direct method described in § 2.2.

$\theta$ to zero. Equation (2.15) is the only aspect of the analysis of Wetzel & Tucker (Reference Wetzel and Tucker2001) that we use. In particular, we eschew using their method of writing the deformation rate and vorticity in the particle in terms of fourth rank ‘concentration tensors’, and use instead the more direct method described in § 2.2.

Substituting ![]() ${\boldsymbol{L}}=\boldsymbol{\mathsf{D}}+\boldsymbol{\mathsf{W}}$, the diagonal components of (2.15) give relations for the time evolution of the semi-axis lengths,

${\boldsymbol{L}}=\boldsymbol{\mathsf{D}}+\boldsymbol{\mathsf{W}}$, the diagonal components of (2.15) give relations for the time evolution of the semi-axis lengths,

and the off-diagonal 1–2 component yields the evolution equation for the orientation

At steady state, (2.17) yields the linear relation between ![]() $D_{12}$ and

$D_{12}$ and ![]() $W_{12}$ obtained by Roscoe (Reference Roscoe1967).

$W_{12}$ obtained by Roscoe (Reference Roscoe1967).

2.4. Stress in the particle

We model the particle as an incompressible neo-Hookean solid, satisfying the constitutive relation

where ![]() $p$ is the pressure in the solid that varies so as to enforce incompressibility,

$p$ is the pressure in the solid that varies so as to enforce incompressibility, ![]() ${\boldsymbol{\mathsf{B}}}$ is the configuration dependent finger tensor (or the left Cauchy–Green deformation tensor) and

${\boldsymbol{\mathsf{B}}}$ is the configuration dependent finger tensor (or the left Cauchy–Green deformation tensor) and ![]() $\eta$ is the elastic modulus. The finger tensor is defined as

$\eta$ is the elastic modulus. The finger tensor is defined as ![]() ${\boldsymbol{\mathsf{B}}} = {\boldsymbol {F}} \boldsymbol{\cdot} {\boldsymbol {F}}^{{\rm T}}$, where

${\boldsymbol{\mathsf{B}}} = {\boldsymbol {F}} \boldsymbol{\cdot} {\boldsymbol {F}}^{{\rm T}}$, where ![]() ${\boldsymbol {F}}={\boldsymbol {{\partial x}/{\partial X}}}$ is the deformation gradient tensor relating the configuration at time

${\boldsymbol {F}}={\boldsymbol {{\partial x}/{\partial X}}}$ is the deformation gradient tensor relating the configuration at time ![]() $t$ to the stress-free initial configuration. Note that (2.18) gives the stress in dimensional form; when scaled by

$t$ to the stress-free initial configuration. Note that (2.18) gives the stress in dimensional form; when scaled by ![]() $\mu \dot \gamma$ (see § 2.1), the dimensionless extra stress is

$\mu \dot \gamma$ (see § 2.1), the dimensionless extra stress is ![]() ${\boldsymbol{\mathsf{\tau}}} = ({1}/{G}) ({\boldsymbol{\mathsf{B}}}-{\boldsymbol{\mathsf{I}}})$, where

${\boldsymbol{\mathsf{\tau}}} = ({1}/{G}) ({\boldsymbol{\mathsf{B}}}-{\boldsymbol{\mathsf{I}}})$, where ![]() $G \equiv \mu \dot \gamma /\eta$ is the elastic capillary number. Determination of the stress requires

$G \equiv \mu \dot \gamma /\eta$ is the elastic capillary number. Determination of the stress requires ![]() ${\boldsymbol {F}}$, which we determine below from the deformation history of the particle.

${\boldsymbol {F}}$, which we determine below from the deformation history of the particle.

2.4.1. Particle deformation in a small time interval  $\delta t$

$\delta t$

Consider a time ![]() $t_i$ at which the shape (

$t_i$ at which the shape (![]() $\alpha _1$,

$\alpha _1$, ![]() $\alpha _2$,

$\alpha _2$, ![]() $\alpha _3$) and orientation (

$\alpha _3$) and orientation (![]() $\theta$) of the particle are known (figure 3a). We determine the deformation in the time interval

$\theta$) of the particle are known (figure 3a). We determine the deformation in the time interval ![]() $\delta t$ that is small enough that the stress in the particle can be assumed to remain constant. The particle undergoes an in-plane rotation through an angle

$\delta t$ that is small enough that the stress in the particle can be assumed to remain constant. The particle undergoes an in-plane rotation through an angle ![]() $-\zeta$ due to vorticity (see figure 3b). It also undergoes deformation by in-plane stretches

$-\zeta$ due to vorticity (see figure 3b). It also undergoes deformation by in-plane stretches ![]() $\lambda _1$ and

$\lambda _1$ and ![]() $\lambda _2$ (

$\lambda _2$ (![]() $\lambda _1 > \lambda _2$) (ratios of deformed lengths to original lengths of a differential material element) oriented at angles

$\lambda _1 > \lambda _2$) (ratios of deformed lengths to original lengths of a differential material element) oriented at angles ![]() $\varphi$ and

$\varphi$ and ![]() $\varphi + {\rm \pi}/2$, respectively, to the

$\varphi + {\rm \pi}/2$, respectively, to the ![]() $x_1$ axis of the particle (see figure 3c); incompressibility requires the particle to be stretched by

$x_1$ axis of the particle (see figure 3c); incompressibility requires the particle to be stretched by ![]() $\lambda _3 = 1/(\lambda _1 \lambda _2)$ in the 3-direction. Due to the misalignment between the directions of stretch and the particle axes, the orientation further changes such that the extensional stretch axis (

$\lambda _3 = 1/(\lambda _1 \lambda _2)$ in the 3-direction. Due to the misalignment between the directions of stretch and the particle axes, the orientation further changes such that the extensional stretch axis (![]() $\lambda _1$ axis) subtends an angle

$\lambda _1$ axis) subtends an angle ![]() $\psi$ with the

$\psi$ with the ![]() $x_1$ axis (figure 3f). All angles are defined as positive in the anti-clockwise direction. Note that the angles of rotation

$x_1$ axis (figure 3f). All angles are defined as positive in the anti-clockwise direction. Note that the angles of rotation ![]() $\zeta$ and

$\zeta$ and ![]() $\psi - \varphi$, and the deviations of the stretches from unity

$\psi - \varphi$, and the deviations of the stretches from unity ![]() $\lambda _1 - 1$ and

$\lambda _1 - 1$ and ![]() $\lambda _2 - 1$ are all proportional to

$\lambda _2 - 1$ are all proportional to ![]() $\delta t$. As a result of the changes in orientation due to vorticity and stretch, the orientation

$\delta t$. As a result of the changes in orientation due to vorticity and stretch, the orientation ![]() $\theta '$ at

$\theta '$ at ![]() $t_{i+1} = t_i + \delta t$ is

$t_{i+1} = t_i + \delta t$ is

Figure 3. Sequence of steps involved in mapping a material point from time ![]() $t_i$ to

$t_i$ to ![]() $t_{i+1}$. All angles are positive in the anti-clockwise direction. (a) Particle at initial orientation

$t_{i+1}$. All angles are positive in the anti-clockwise direction. (a) Particle at initial orientation ![]() $\theta$. (b) In-plane rotation of the particle due to the (uniform) vorticity field in the particle by an angle

$\theta$. (b) In-plane rotation of the particle due to the (uniform) vorticity field in the particle by an angle ![]() $-\zeta$. After rotation, the extensional stretch axis (

$-\zeta$. After rotation, the extensional stretch axis (![]() $\lambda _1$ axis) subtends an angle

$\lambda _1$ axis) subtends an angle ![]() $\varphi$ with the

$\varphi$ with the ![]() $x_1$ axis of the particle. (c) Stretching of the particle due to the (uniform) strain rate at an angle

$x_1$ axis of the particle. (c) Stretching of the particle due to the (uniform) strain rate at an angle ![]() $\varphi$ from its principal axes. After stretching, the extensional stretch axis subtends an angle

$\varphi$ from its principal axes. After stretching, the extensional stretch axis subtends an angle ![]() $\psi$ with the

$\psi$ with the ![]() $x_1$ axis. (d,e) Virtual transformations to effect stretching: in (d) the particle is rotated by

$x_1$ axis. (d,e) Virtual transformations to effect stretching: in (d) the particle is rotated by ![]() $-(\theta - \zeta + \varphi )$ so that the stretch axes are aligned with the laboratory axes; in (e) the particle undergoes stretches of

$-(\theta - \zeta + \varphi )$ so that the stretch axes are aligned with the laboratory axes; in (e) the particle undergoes stretches of ![]() $\lambda _1$,

$\lambda _1$, ![]() $\lambda _2$,

$\lambda _2$, ![]() $\lambda _3$ along the laboratory axes. After stretching, it is rotated by

$\lambda _3$ along the laboratory axes. After stretching, it is rotated by ![]() $(\theta - \zeta + \varphi )$. ( f) The conformation of the particle at

$(\theta - \zeta + \varphi )$. ( f) The conformation of the particle at ![]() $t_{i+1}$, after rotation and stretching.

$t_{i+1}$, after rotation and stretching.

Following the rotation and stretch, the mapping between positions of a material point, expressed in the laboratory reference frame, at times ![]() $t_i$ and

$t_i$ and ![]() $t_{i+1}$ is

$t_{i+1}$ is

where ![]() ${\boldsymbol{\mathsf{T}}}$ is the diagonal stretch tensor with components

${\boldsymbol{\mathsf{T}}}$ is the diagonal stretch tensor with components ![]() $T_{ii} = \lambda _i$ and

$T_{ii} = \lambda _i$ and ![]() $\boldsymbol{\mathsf{R}}$ is the rotation tensor defined in § 2.3. The combination

$\boldsymbol{\mathsf{R}}$ is the rotation tensor defined in § 2.3. The combination ![]() ${\boldsymbol{\mathsf{R}}}(\theta -\zeta + \varphi ) \boldsymbol{\cdot} {\boldsymbol{\mathsf{T}}} \boldsymbol{\cdot} {\boldsymbol{\mathsf{R}}}(-\theta + \zeta - \varphi )$ serves to transform the diagonal stretch tensor to the laboratory reference frame by accounting for the angle

${\boldsymbol{\mathsf{R}}}(\theta -\zeta + \varphi ) \boldsymbol{\cdot} {\boldsymbol{\mathsf{T}}} \boldsymbol{\cdot} {\boldsymbol{\mathsf{R}}}(-\theta + \zeta - \varphi )$ serves to transform the diagonal stretch tensor to the laboratory reference frame by accounting for the angle ![]() $\theta - \zeta + \varphi$ between the

$\theta - \zeta + \varphi$ between the ![]() $\lambda _1$ axis of stretch and the flow direction (see figure 3c). Equation (2.20) may be written as

$\lambda _1$ axis of stretch and the flow direction (see figure 3c). Equation (2.20) may be written as

where ![]() ${\boldsymbol {F}}^i$ is the deformation gradient tensor in the laboratory reference frame whose components have the values

${\boldsymbol {F}}^i$ is the deformation gradient tensor in the laboratory reference frame whose components have the values

\begin{equation} \left. \begin{aligned} F^i_{11} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\cos \zeta + (\lambda_1-\lambda_2)\cos (2\theta + 2\varphi - \zeta) \}, \\ F^i_{12} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\sin \zeta + (\lambda_1-\lambda_2)\sin (2\theta + 2\varphi - \zeta) \}, \\ F^i_{21} & = \tfrac{1}{2}\{-(\lambda_1+\lambda_2)\sin \zeta + (\lambda_1-\lambda_2)\sin (2\theta + 2\varphi - \zeta) \}, \\ F^i_{22} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\cos \zeta - (\lambda_1-\lambda_2)\cos (2\theta + 2\varphi - \zeta) \} \\ F^i_{13} & = F^i_{23} = F^i_{31} = F^i_{32} = 0; \quad F^i_{33} = \lambda_3. \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} F^i_{11} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\cos \zeta + (\lambda_1-\lambda_2)\cos (2\theta + 2\varphi - \zeta) \}, \\ F^i_{12} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\sin \zeta + (\lambda_1-\lambda_2)\sin (2\theta + 2\varphi - \zeta) \}, \\ F^i_{21} & = \tfrac{1}{2}\{-(\lambda_1+\lambda_2)\sin \zeta + (\lambda_1-\lambda_2)\sin (2\theta + 2\varphi - \zeta) \}, \\ F^i_{22} & = \tfrac{1}{2}\{(\lambda_1+\lambda_2)\cos \zeta - (\lambda_1-\lambda_2)\cos (2\theta + 2\varphi - \zeta) \} \\ F^i_{13} & = F^i_{23} = F^i_{31} = F^i_{32} = 0; \quad F^i_{33} = \lambda_3. \end{aligned} \right\} \end{equation}2.4.2. Relating the shape and orientation to the strain rate and vorticity

To evaluate ![]() ${\boldsymbol {F}}^i$, we need the values of

${\boldsymbol {F}}^i$, we need the values of ![]() $\lambda _1$,

$\lambda _1$, ![]() $\lambda _2$,

$\lambda _2$, ![]() $\zeta$,

$\zeta$, ![]() $\varphi$ and

$\varphi$ and ![]() $\psi$. From (2.17) and (2.19), the change in orientation due to vorticity and stretching, respectively, are given by

$\psi$. From (2.17) and (2.19), the change in orientation due to vorticity and stretching, respectively, are given by

with errors of O(![]() $\delta t^2$). An additional equation comes from the condition that there is no shear along the principal stretch directions. It then follows from Mohr's circle for the strain rate that

$\delta t^2$). An additional equation comes from the condition that there is no shear along the principal stretch directions. It then follows from Mohr's circle for the strain rate that

The relations (2.16) and (2.23) over the time step ![]() $\delta t$ along with (2.24) give us updated lengths

$\delta t$ along with (2.24) give us updated lengths ![]() $\alpha _i$ of the semi-axes and the orientation

$\alpha _i$ of the semi-axes and the orientation ![]() $\theta '$, and the angles

$\theta '$, and the angles ![]() $\zeta$,

$\zeta$, ![]() $\varphi$ and

$\varphi$ and ![]() $\psi$.

$\psi$.

It now remains to calculate the stretches ![]() $\lambda _1$ and

$\lambda _1$ and ![]() $\lambda _2$ to obtain the deformation gradient tensor. For this, we consider the shape of the particle after it is stretched by the principal stretch tensor

$\lambda _2$ to obtain the deformation gradient tensor. For this, we consider the shape of the particle after it is stretched by the principal stretch tensor ![]() ${\boldsymbol{\mathsf{T}}}$. Consider the particle in figure 3(d), where it has been rotated so that the principal stretch axes align with the laboratory axes. The equation of the in-plane cross-section of the particle in laboratory coordinates before stretching is that of an ellipse at an angle

${\boldsymbol{\mathsf{T}}}$. Consider the particle in figure 3(d), where it has been rotated so that the principal stretch axes align with the laboratory axes. The equation of the in-plane cross-section of the particle in laboratory coordinates before stretching is that of an ellipse at an angle ![]() $-\varphi$ to the 1-axis. Stretching transforms each point (

$-\varphi$ to the 1-axis. Stretching transforms each point (![]() $y_1$,

$y_1$, ![]() $y_2$,

$y_2$, ![]() $y_3$) in the ellipsoid to (

$y_3$) in the ellipsoid to (![]() $\lambda _1 y_1$,

$\lambda _1 y_1$, ![]() $\lambda _2 y_2$,

$\lambda _2 y_2$, ![]() $\lambda _3 y_3$), whence the equation of the cross-section after stretching is

$\lambda _3 y_3$), whence the equation of the cross-section after stretching is

The principal axis of the particle is now at an angle ![]() $-\psi$ to the 1-axis (figure 3e), and its semi-axis lengths have changed to (

$-\psi$ to the 1-axis (figure 3e), and its semi-axis lengths have changed to (![]() $\alpha _1'$,

$\alpha _1'$, ![]() $\alpha _2'$,

$\alpha _2'$, ![]() $\alpha _3'$), which are obtained by integrating (2.16) over the time interval

$\alpha _3'$), which are obtained by integrating (2.16) over the time interval ![]() $\delta t$. The equation of the cross-section can therefore be equivalently be written as

$\delta t$. The equation of the cross-section can therefore be equivalently be written as

Comparing the coefficients of ![]() $y_1^2$ and

$y_1^2$ and ![]() $y_2^2$ in (2.25) and (2.26), we get the required expressions for

$y_2^2$ in (2.25) and (2.26), we get the required expressions for ![]() $\lambda _1$ and

$\lambda _1$ and ![]() $\lambda _2$

$\lambda _2$

\begin{equation} \lambda_{1} =

\left(\dfrac{\dfrac{\cos^{2}\varphi}{\alpha_{1}^{2}} +

\dfrac{\sin^{2}\varphi}{\alpha_{2}^{2}}}{\dfrac{\cos^{2}\psi}{\alpha_{1}'^{2}}

+ \dfrac{\sin^{2}\psi}{\alpha_{2}'^{2}}}\right)^{{1}/{2}},

\quad \lambda_{2} =

\left(\dfrac{\dfrac{\sin^{2}\varphi}{\alpha_{1}^{2}} +

\dfrac{\cos^{2}\varphi}{\alpha_{2}^{2}}}{\dfrac{\sin^{2}\psi}{\alpha_{1}'^{2}}

+ \dfrac{\cos^{2}\psi}{\alpha_{2}'^{2}}}\right)^{{1}/{2}}.

\end{equation}

\begin{equation} \lambda_{1} =

\left(\dfrac{\dfrac{\cos^{2}\varphi}{\alpha_{1}^{2}} +

\dfrac{\sin^{2}\varphi}{\alpha_{2}^{2}}}{\dfrac{\cos^{2}\psi}{\alpha_{1}'^{2}}

+ \dfrac{\sin^{2}\psi}{\alpha_{2}'^{2}}}\right)^{{1}/{2}},

\quad \lambda_{2} =

\left(\dfrac{\dfrac{\sin^{2}\varphi}{\alpha_{1}^{2}} +

\dfrac{\cos^{2}\varphi}{\alpha_{2}^{2}}}{\dfrac{\sin^{2}\psi}{\alpha_{1}'^{2}}

+ \dfrac{\cos^{2}\psi}{\alpha_{2}'^{2}}}\right)^{{1}/{2}}.

\end{equation}

2.4.3. Particle stress in terms of the kinematic variables

The deformation gradient tensor ![]() ${\boldsymbol {F}}^i$ in (2.22) relates positions of material points in the laboratory coordinate system between times

${\boldsymbol {F}}^i$ in (2.22) relates positions of material points in the laboratory coordinate system between times ![]() $t_{i+1}$ and

$t_{i+1}$ and ![]() $t_i$. However, the constitutive relation for the elastic stress requires the deformation gradient

$t_i$. However, the constitutive relation for the elastic stress requires the deformation gradient ![]() ${\boldsymbol {F}}$ that relates the configuration at time

${\boldsymbol {F}}$ that relates the configuration at time ![]() $t_{i+1}$ to the stress-free configuration at

$t_{i+1}$ to the stress-free configuration at ![]() $t_0 = 0$. This is simply the time-ordered contraction of

$t_0 = 0$. This is simply the time-ordered contraction of ![]() ${\boldsymbol {F}}^i$ at all intermediate states

${\boldsymbol {F}}^i$ at all intermediate states

The finger tensor in the fixed laboratory coordinate frame then is ![]() ${\boldsymbol{\mathsf{B}}}_{lab} = {\boldsymbol {F}} \boldsymbol{\cdot} {\boldsymbol {F}}^{\rm T}$. As we require the particle stress in the coordinate system aligned with its principal axes (which subtend an angle of

${\boldsymbol{\mathsf{B}}}_{lab} = {\boldsymbol {F}} \boldsymbol{\cdot} {\boldsymbol {F}}^{\rm T}$. As we require the particle stress in the coordinate system aligned with its principal axes (which subtend an angle of ![]() $\theta '$ with fixed laboratory coordinates),

$\theta '$ with fixed laboratory coordinates),

is the appropriate finger tensor to determine the stress in (2.18).

2.5. Extension to viscoelastic particles

For a viscoelastic solid, the total stress is the sum of elastic and viscous contributions, ![]() ${{\boldsymbol{\sigma} }}^p = {{\boldsymbol{\sigma} }}^e + {{\boldsymbol{\sigma} }}^v$. Determination of the elastic stress

${{\boldsymbol{\sigma} }}^p = {{\boldsymbol{\sigma} }}^e + {{\boldsymbol{\sigma} }}^v$. Determination of the elastic stress ![]() ${{\boldsymbol{\sigma} }}^e$ has already been outlined in § 2.4; the viscous contribution is

${{\boldsymbol{\sigma} }}^e$ has already been outlined in § 2.4; the viscous contribution is ![]() ${{\boldsymbol{\sigma} }}^v = 2\kappa \boldsymbol{\mathsf{D}}$, where

${{\boldsymbol{\sigma} }}^v = 2\kappa \boldsymbol{\mathsf{D}}$, where ![]() $\kappa$ is the viscosity ratio of the particle to the fluid. Balancing the normal and tangential components of the traction at the surface of the particle, and following the same procedure as in § 2.2 to eliminate the pressure, we get the following equations that extend (2.8) and (2.14) for a viscoelastic particle:

$\kappa$ is the viscosity ratio of the particle to the fluid. Balancing the normal and tangential components of the traction at the surface of the particle, and following the same procedure as in § 2.2 to eliminate the pressure, we get the following equations that extend (2.8) and (2.14) for a viscoelastic particle:

\begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}-{\boldsymbol{\mathsf{\sigma}}}^p_{22} &= ({\boldsymbol{\mathsf{\sigma}}}^e_{11}-{\boldsymbol{\mathsf{\sigma}}}^e_{22}) + 2 \kappa \left(D_{11}-D_{22} \right) \nonumber\\ &= 5 \left(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right)\right) \nonumber\\ &\quad + 2 \left(D_{11}-D_{22}\right), \end{align}

\begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}-{\boldsymbol{\mathsf{\sigma}}}^p_{22} &= ({\boldsymbol{\mathsf{\sigma}}}^e_{11}-{\boldsymbol{\mathsf{\sigma}}}^e_{22}) + 2 \kappa \left(D_{11}-D_{22} \right) \nonumber\\ &= 5 \left(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right)\right) \nonumber\\ &\quad + 2 \left(D_{11}-D_{22}\right), \end{align} \begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}+{\boldsymbol{\mathsf{\sigma}}}^p_{22}-2{\boldsymbol{\mathsf{\sigma}}}^p_{33} &= ({\boldsymbol{\mathsf{\sigma}}}^e_{11} +{\boldsymbol{\mathsf{\sigma}}}^e_{22}-2{\boldsymbol{\mathsf{\sigma}}}^e_{33})+ 6 \kappa \left(D_{11}-D_{22}\right) \nonumber\\ &= 5(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right) \nonumber\\ &\quad + 2 \left(I_{23} - J_{23}\right)\left(\left(D^{\infty}_{11}-D_{11}\right)+\left(D^{\infty}_{22}-D_{22}\right)\right)) \nonumber\\ &\quad + 6 \left(D_{11}-D_{22}\right), \end{align}

\begin{align} {\boldsymbol{\mathsf{\sigma}}}^p_{11}+{\boldsymbol{\mathsf{\sigma}}}^p_{22}-2{\boldsymbol{\mathsf{\sigma}}}^p_{33} &= ({\boldsymbol{\mathsf{\sigma}}}^e_{11} +{\boldsymbol{\mathsf{\sigma}}}^e_{22}-2{\boldsymbol{\mathsf{\sigma}}}^e_{33})+ 6 \kappa \left(D_{11}-D_{22}\right) \nonumber\\ &= 5(\left(I_{12} + J_{12}\right)\left(D^{\infty}_{11}-D_{11}\right) + \left(I_{12} - J_{12}\right)\left(D^{\infty}_{22}-D_{22}\right) \nonumber\\ &\quad + 2 \left(I_{23} - J_{23}\right)\left(\left(D^{\infty}_{11}-D_{11}\right)+\left(D^{\infty}_{22}-D_{22}\right)\right)) \nonumber\\ &\quad + 6 \left(D_{11}-D_{22}\right), \end{align} \begin{align}{\boldsymbol{\mathsf{\sigma}}}^p_{12} &= {\boldsymbol{\mathsf{\sigma}}}^e_{12} + 2 \kappa D_{12} \nonumber\\ &=\frac{8\left[g_1+\alpha_{2}^{2} g'_3 \left(\dfrac{\alpha_{1}^2 - \alpha_{2}^2}{\alpha_{1}^2 + \alpha_{2}^2}\right)\right](D^{\infty}_{12}-D_{12}) }{2~g'_3(\alpha_{1}^{2} g_1 + \alpha_{2}^{2} g_2)} + 2 D_{12} . \end{align}

\begin{align}{\boldsymbol{\mathsf{\sigma}}}^p_{12} &= {\boldsymbol{\mathsf{\sigma}}}^e_{12} + 2 \kappa D_{12} \nonumber\\ &=\frac{8\left[g_1+\alpha_{2}^{2} g'_3 \left(\dfrac{\alpha_{1}^2 - \alpha_{2}^2}{\alpha_{1}^2 + \alpha_{2}^2}\right)\right](D^{\infty}_{12}-D_{12}) }{2~g'_3(\alpha_{1}^{2} g_1 + \alpha_{2}^{2} g_2)} + 2 D_{12} . \end{align}

Again, cyclic permutation of indices in ![]() ${\boldsymbol{\mathsf{\sigma}}} ^p_{12}$ provides the expressions for

${\boldsymbol{\mathsf{\sigma}}} ^p_{12}$ provides the expressions for ![]() ${\boldsymbol{\mathsf{\sigma}}} ^p_{23}$ and

${\boldsymbol{\mathsf{\sigma}}} ^p_{23}$ and ![]() ${\boldsymbol{\mathsf{\sigma}}} ^p_{13}$. The components of the strain rate and vorticity fields in the viscoelastic particle can be obtained by solving (2.30) and are given in § B.2 of Appendix B.

${\boldsymbol{\mathsf{\sigma}}} ^p_{13}$. The components of the strain rate and vorticity fields in the viscoelastic particle can be obtained by solving (2.30) and are given in § B.2 of Appendix B.

2.6. Calculation of rheological properties

The bulk stress in the suspension is ![]() $\langle {{{\boldsymbol{\sigma} }}}\rangle =\phi \langle {{\boldsymbol{\sigma} }}\rangle ^p +(1-\phi )\langle {{{\boldsymbol{\sigma} }}}\rangle ^f$, where

$\langle {{{\boldsymbol{\sigma} }}}\rangle =\phi \langle {{\boldsymbol{\sigma} }}\rangle ^p +(1-\phi )\langle {{{\boldsymbol{\sigma} }}}\rangle ^f$, where ![]() $\phi$ is the particle volume fraction and the angle brackets represent volume averages. Similarly, the bulk strain rate of the suspension can be expressed in terms of the respective averages in the two phases,

$\phi$ is the particle volume fraction and the angle brackets represent volume averages. Similarly, the bulk strain rate of the suspension can be expressed in terms of the respective averages in the two phases, ![]() $\langle {\boldsymbol{\mathsf{D}}}\rangle =\phi \langle {\boldsymbol{\mathsf{D}}}\rangle ^p +(1-\phi )\langle {\boldsymbol{\mathsf{D}}}\rangle ^f$. Therefore, the suspension stress is

$\langle {\boldsymbol{\mathsf{D}}}\rangle =\phi \langle {\boldsymbol{\mathsf{D}}}\rangle ^p +(1-\phi )\langle {\boldsymbol{\mathsf{D}}}\rangle ^f$. Therefore, the suspension stress is

Note that the bulk strain rate and vorticity are identical to the externally imposed flow quantities, i.e. ![]() $\langle {\boldsymbol{\mathsf{D}}}\rangle =\boldsymbol{\mathsf{D}}^{\infty}$ and

$\langle {\boldsymbol{\mathsf{D}}}\rangle =\boldsymbol{\mathsf{D}}^{\infty}$ and ![]() $\langle {\boldsymbol{\mathsf{W}}}\rangle =\boldsymbol{\mathsf{W}}^{\infty}$.

$\langle {\boldsymbol{\mathsf{W}}}\rangle =\boldsymbol{\mathsf{W}}^{\infty}$.

We consider the suspension to be composed of ellipsoids of identical size but different orientations in the initial (stress-free) state. As the suspension is dilute enough that particles do not interact, the undisturbed flow experienced by each particle is the imposed linear flow, for which the strain rate and stress within each particle at each instant of time are uniform. As a result, ![]() $\langle {\boldsymbol{\mathsf{\tau}}}^{p} \rangle$ and

$\langle {\boldsymbol{\mathsf{\tau}}}^{p} \rangle$ and ![]() $\langle \boldsymbol{\mathsf{D}}^{p} \rangle$ represent averages over the orientation of a single particle. We find that the long-time orientation dynamics for initial ellipsoidal particles is identical, to within a phase lag, regardless of the initial orientation; the phase lag is a residual signature of the short transient associated with the stress-free initial orientation. Therefore, the long-time average for ellipsoids over all initial orientations is identical to the average over a time period of tumbling or trembling; for initially spherical particles it is trivially the steady state.

$\langle \boldsymbol{\mathsf{D}}^{p} \rangle$ represent averages over the orientation of a single particle. We find that the long-time orientation dynamics for initial ellipsoidal particles is identical, to within a phase lag, regardless of the initial orientation; the phase lag is a residual signature of the short transient associated with the stress-free initial orientation. Therefore, the long-time average for ellipsoids over all initial orientations is identical to the average over a time period of tumbling or trembling; for initially spherical particles it is trivially the steady state.

The rheological properties of interest then are the intrinsic shear viscosity

\begin{equation} [\mu]_s = \frac{\dfrac{\langle{{\boldsymbol{\mathsf{\sigma}}}}\rangle_{12}}{2{D}^{\infty}_{12}}-1}{\phi} = \langle \tau \rangle^{p}_{12} - 2 \langle D \rangle^p_{12}, \end{equation}

\begin{equation} [\mu]_s = \frac{\dfrac{\langle{{\boldsymbol{\mathsf{\sigma}}}}\rangle_{12}}{2{D}^{\infty}_{12}}-1}{\phi} = \langle \tau \rangle^{p}_{12} - 2 \langle D \rangle^p_{12}, \end{equation}and the intrinsic normal stress differences in simple shear flow

3. Results and discussion

3.1. Dynamics of an elastic particle in simple shear flow

We study the shape dynamics of neutrally buoyant elastic particles whose initial (stress-free) shape is a sphere, a spheroid and, more generally, a triaxial ellipsoid, suspended in an unbounded Newtonian fluid subjected to simple shear. As mentioned in § 1, the shape dynamics of an initial sphere and prolate spheroid were reported earlier by Gao et al. (Reference Gao, Hu and Castañeda2011, Reference Gao, Hu and Castaneda2012). We validate our solution method by a comparison with their results; the comparison is provided in Appendix C, where it is shown that the two sets of results are identical. Thus, the primary new results reported here concern the in-plane dynamics of oblate spheroids and triaxial ellipsoids.

3.1.1. Dynamics of oblate spheroids and triaxial ellipsoids

As in the case of prolate spheroids (Gao et al. Reference Gao, Hu and Castaneda2012), oblate spheroids and triaxial ellipsoids too exhibit trembling and tumbling dynamics. We first discuss the shape dynamics of oblate spheroids. For a given initial aspect ratio ![]() $\omega _{1,0} = \omega _{2,0} = \omega _0$, the particle deforms to resemble a thin disk for part of its tumbling/trembling cycle as the elastic capillary number

$\omega _{1,0} = \omega _{2,0} = \omega _0$, the particle deforms to resemble a thin disk for part of its tumbling/trembling cycle as the elastic capillary number ![]() $G$ increases. Since

$G$ increases. Since ![]() $G$ may be thought of as the inverse of the dimensionless stiffness, increasing

$G$ may be thought of as the inverse of the dimensionless stiffness, increasing ![]() $G$ implies increasing deformability. The transition from tumbling to trembling occurs at a critical value of

$G$ implies increasing deformability. The transition from tumbling to trembling occurs at a critical value of ![]() $G$ that depends on

$G$ that depends on ![]() $\omega _0$. Figures 4 and 5 show the results for two values of

$\omega _0$. Figures 4 and 5 show the results for two values of ![]() $G$ for

$G$ for ![]() $\omega _0=2.5$ on either side of the tumbling–trembling transition for an initial orientation of

$\omega _0=2.5$ on either side of the tumbling–trembling transition for an initial orientation of ![]() $\theta _0={\rm \pi} /2$ (i.e. the symmetry axis pointing in the velocity gradient direction). It is evident from figure 4(b) that the particle tumbles for

$\theta _0={\rm \pi} /2$ (i.e. the symmetry axis pointing in the velocity gradient direction). It is evident from figure 4(b) that the particle tumbles for ![]() $G=0.4$ and trembles for

$G=0.4$ and trembles for ![]() $G=0.5$.

$G=0.5$.

Figure 4. Dynamics of an initially oblate spheroid exhibiting trembling and tumbling dynamics at ![]() $\omega _0 = 2.5$. (a) In-plane and out-of-plane aspect ratios. (b) Orientation of the

$\omega _0 = 2.5$. (a) In-plane and out-of-plane aspect ratios. (b) Orientation of the ![]() $x_1$ axis. The stress polarization results were obtained using the method of Gao et al. (Reference Gao, Hu and Castañeda2011).

$x_1$ axis. The stress polarization results were obtained using the method of Gao et al. (Reference Gao, Hu and Castañeda2011).

Figure 5. (a,b) The time variation of the direction of stretch (![]() $\varphi$) for the two cases shown in figure 4, namely

$\varphi$) for the two cases shown in figure 4, namely ![]() $G=0.4$ (a) and

$G=0.4$ (a) and ![]() $G=0.5$ (b). The particle orientation from figure 4(b) is superposed. (c,d) The contributions to the change in orientation due to the vorticity (

$G=0.5$ (b). The particle orientation from figure 4(b) is superposed. (c,d) The contributions to the change in orientation due to the vorticity (![]() $-\zeta$) and stretch (

$-\zeta$) and stretch (![]() $\varphi -\psi$), and the net change (

$\varphi -\psi$), and the net change (![]() $\varphi -\psi -\zeta$) during each time step corresponding to panels (a,b). Refer to figure 3 for the definitions of the angles

$\varphi -\psi -\zeta$) during each time step corresponding to panels (a,b). Refer to figure 3 for the definitions of the angles ![]() $\zeta$,

$\zeta$, ![]() $\phi$ and

$\phi$ and ![]() $\varphi$. The time step

$\varphi$. The time step ![]() $\delta t$ is not constant, as it has to be adaptively changed to accurately compute sharp changes.

$\delta t$ is not constant, as it has to be adaptively changed to accurately compute sharp changes.

Figure 5(a,b) shows the variations with time of the orientation ![]() $\theta$ and the angle

$\theta$ and the angle ![]() $\varphi$ between the

$\varphi$ between the ![]() $x_1$ axis and tensile stretch axis. Recall from § 2.1 that the

$x_1$ axis and tensile stretch axis. Recall from § 2.1 that the ![]() $x_1$ axis (which characterizes the orientation

$x_1$ axis (which characterizes the orientation ![]() $\theta$) for an oblate spheroid is the in-plane principal axis of smaller length. For the stiffer particle (

$\theta$) for an oblate spheroid is the in-plane principal axis of smaller length. For the stiffer particle (![]() $G=0.4$),

$G=0.4$), ![]() $\varphi$ changes sign twice during a revolution (figure 5a), implying tumbling motion. The transition may be understood by considering the contributions to rotation from stretching and vorticity in every time step

$\varphi$ changes sign twice during a revolution (figure 5a), implying tumbling motion. The transition may be understood by considering the contributions to rotation from stretching and vorticity in every time step ![]() $\delta t$, shown in figure 5(c). We see that, although the orientation change due to stretching

$\delta t$, shown in figure 5(c). We see that, although the orientation change due to stretching ![]() $\varphi -\psi$ is positive for part of each cycle, it is smaller in magnitude than the orientation change due to vorticity

$\varphi -\psi$ is positive for part of each cycle, it is smaller in magnitude than the orientation change due to vorticity ![]() $-\zeta$; the net change in orientation

$-\zeta$; the net change in orientation ![]() $(\varphi - \psi ) - \zeta$ is therefore always negative, resulting in tumbling. For the softer particle (

$(\varphi - \psi ) - \zeta$ is therefore always negative, resulting in tumbling. For the softer particle (![]() $G=0.5$),

$G=0.5$), ![]() $\varphi$ is always negative (figure 5b), implying that the

$\varphi$ is always negative (figure 5b), implying that the ![]() $x_1$ axis lies between the flow direction and the direction of extensional stretch (

$x_1$ axis lies between the flow direction and the direction of extensional stretch (![]() $\lambda _1$); the orientation change due to stretch is therefore always positive (figure 5d); it is also larger in magnitude that the orientation change due to vorticity. As a result, the particle trembles – the orientation oscillates about an angle that depends on

$\lambda _1$); the orientation change due to stretch is therefore always positive (figure 5d); it is also larger in magnitude that the orientation change due to vorticity. As a result, the particle trembles – the orientation oscillates about an angle that depends on ![]() $G$ and

$G$ and ![]() $\omega _0$. The sharp peaks in figure 5(c,d) correspond to instances when the in-plane aspect ratio (

$\omega _0$. The sharp peaks in figure 5(c,d) correspond to instances when the in-plane aspect ratio (![]() $\omega _1$) is close to unity (figure 4a), about which there is rapid variation in

$\omega _1$) is close to unity (figure 4a), about which there is rapid variation in ![]() $\varphi$ (figure 5a,b). The results presented in figures 4 and 5 are for an initial orientation wherein the

$\varphi$ (figure 5a,b). The results presented in figures 4 and 5 are for an initial orientation wherein the ![]() $x_1$ axis is aligned with the gradient direction. Any other initial orientation in the plane of shear simply leads to the same dynamics at large time, apart from a short initial transient. Thus, the only signature of the initial orientation is a phase difference in the universal long-time dynamics.

$x_1$ axis is aligned with the gradient direction. Any other initial orientation in the plane of shear simply leads to the same dynamics at large time, apart from a short initial transient. Thus, the only signature of the initial orientation is a phase difference in the universal long-time dynamics.

For very stiff particles, such as ![]() $G=0.01$, the orientation of the principal stretch axis exhibits the same qualitative dynamics as that in figure 5(a) for

$G=0.01$, the orientation of the principal stretch axis exhibits the same qualitative dynamics as that in figure 5(a) for ![]() $G=0.4$. The transition from tumbling to trembling (for a fixed

$G=0.4$. The transition from tumbling to trembling (for a fixed ![]() $\omega _0$) occurs with increasing

$\omega _0$) occurs with increasing ![]() $G$ due to the particle deforming into an increasingly anisotropic shape that causes it to spend enough time in orientations where the longer in-plane axis is close to the flow direction and the rate of rotation is the lowest, allowing the deformed particle to ‘spring back’. It is relevant to contrast the dynamics of elastic and rigid particles (

$G$ due to the particle deforming into an increasingly anisotropic shape that causes it to spend enough time in orientations where the longer in-plane axis is close to the flow direction and the rate of rotation is the lowest, allowing the deformed particle to ‘spring back’. It is relevant to contrast the dynamics of elastic and rigid particles (![]() $G = 0$). As there is no stretch dynamics for the latter, they only tumble. Further, a key difference is that while the stress within the elastic particle remains uniform in the limit

$G = 0$). As there is no stretch dynamics for the latter, they only tumble. Further, a key difference is that while the stress within the elastic particle remains uniform in the limit ![]() $G \to 0$, there is no requirement for the stress to be uniform at

$G \to 0$, there is no requirement for the stress to be uniform at ![]() $G = 0$; indeed the stress in the latter case is indeterminate. However, we show below that the orientation dynamics of very stiff particles is virtually identical to a rigid one, implying that the stress indeterminacy is not of relevance to the dynamics.

$G = 0$; indeed the stress in the latter case is indeterminate. However, we show below that the orientation dynamics of very stiff particles is virtually identical to a rigid one, implying that the stress indeterminacy is not of relevance to the dynamics.

We now come to the shape dynamics of triaxial ellipsoids. Recall from § 2.1 that the ![]() $x_1$ axis in this case is the larger in-plane principal axis in the initial state. Figure 6 displays results for two ellipsoids of different initial aspect ratios with

$x_1$ axis in this case is the larger in-plane principal axis in the initial state. Figure 6 displays results for two ellipsoids of different initial aspect ratios with ![]() $G=0.2$, one exhibiting tumbling dynamics and the other trembling. As the stiffness is reduced, there is always a tumbling to trembling transition, no matter what the initial aspect ratios are, which we discuss below. An interesting aspect of elastic triaxial ellipsoids is that the orientation dynamics depends on the initial out-of-plane aspect ratio

$G=0.2$, one exhibiting tumbling dynamics and the other trembling. As the stiffness is reduced, there is always a tumbling to trembling transition, no matter what the initial aspect ratios are, which we discuss below. An interesting aspect of elastic triaxial ellipsoids is that the orientation dynamics depends on the initial out-of-plane aspect ratio ![]() $\omega _{2,0}$; this is in contrast to rigid ellipsoids, where the dynamics is independent of

$\omega _{2,0}$; this is in contrast to rigid ellipsoids, where the dynamics is independent of ![]() $\omega _{2}$, as shown by Jeffery (Reference Jeffery1922). This difference between rigid and elastic ellipsoids is shown in figure 7; while the orientation dynamics for rigid ellipsoids of different out-of-plane aspect ratios is identical (figure 7a), there is a slow down of the tumbling dynamics for elastic particles with decreasing

$\omega _{2}$, as shown by Jeffery (Reference Jeffery1922). This difference between rigid and elastic ellipsoids is shown in figure 7; while the orientation dynamics for rigid ellipsoids of different out-of-plane aspect ratios is identical (figure 7a), there is a slow down of the tumbling dynamics for elastic particles with decreasing ![]() $\omega _{2,0}$, for small

$\omega _{2,0}$, for small ![]() $G$, and a transition from tumbling to trembling with decreasing

$G$, and a transition from tumbling to trembling with decreasing ![]() $\omega _{2,0}$ at the highest

$\omega _{2,0}$ at the highest ![]() $G$ (figure 7b–d).

$G$ (figure 7b–d).

Figure 6. Dynamics of an initially ellipsoidal elastic particle in the trembling and tumbling regimes at ![]() $G=0.2$. (a) In-plane and out-of-plane aspect ratios. (b) Orientation of the major axis.

$G=0.2$. (a) In-plane and out-of-plane aspect ratios. (b) Orientation of the major axis.

Figure 7. Effect of out-of-plane aspect ratio on the dynamics of an initially ellipsoidal elastic particle with ![]() $\omega _{1,0}=0.4$. (a) Perfectly rigid particle (

$\omega _{1,0}=0.4$. (a) Perfectly rigid particle (![]() $G=0$). (b) Slightly soft particle with

$G=0$). (b) Slightly soft particle with ![]() $G=0.01$. (c) Softer particle with

$G=0.01$. (c) Softer particle with ![]() $G=0.1$. (d) Soft particle with

$G=0.1$. (d) Soft particle with ![]() $G=0.4$.

$G=0.4$.

3.1.2. Phase diagrams of dynamical states for spheroids and triaxial ellipsoids

As already discussed, for a particle that is initially an oblate spheroid of aspect ratio ![]() $\omega _0$, the transition from tumbling to trembling occurs at a critical value of

$\omega _0$, the transition from tumbling to trembling occurs at a critical value of ![]() $G$. Thus, the tumbling–trembling transition can be shown in a

$G$. Thus, the tumbling–trembling transition can be shown in a ![]() $G$–

$G$–![]() $\omega _0$ plot, as in the case of prolate spheroids (Gao et al. Reference Gao, Hu and Castaneda2012). Figure 8 shows the combined phase diagram for prolate and oblate spheroids. We know from Roscoe (Reference Roscoe1967) that an initially spherical particle (