DISCUSSION POINTS

• The renewable energy sources based on growing biomass and any wastes containing carbon are able to substitute the total electric power grid for a series of local electric power grids along the whole country, which will make it possible to reduce the consumption of energy raw materials about three times. Marine wave power plants are able to provide countries with a lot of energy at the cost of electric power about $0.01.

Introduction

How can we imagine a healthy developed country of this and next century? Obviously, at the heart of its rational economy should also be the smart energy, which must be friendly to nature and, of course, fossil fuels should be replaced by surface biomass, which will keep the atmosphere in balance with the life on the surface of the globe. Evidently, in the future solar power will have a significant component. But its important problem is batteries – their production and disposal are quite expensive and polluting. The solution must be sought in new approaches to energy conservation. Wind power can significantly increase capacity, which can be done by pre-accumulating wind energy in the energy of compressed air. New approaches to energy generation, storage, and transmission require rethinking and further development.

Disadvantages of modern power plants

If the power plant produces 100% of the electric power, and 10% is consumed (at night from 23:00 to 7:00 h), then where does the rest of the energy go? Of course, it should go to the ground. If 50–80% of electricity is consumed, where does the rest of the energy go? To the ground.

If the consumer is 500 km away from the producer, what are the energy losses? For every 100 km of energy delivery, 10% of energy is lost in summer (up to 15% in winter) due to heating of networks (wires). And that is not all. Additional losses: coronation – up to 17% (air ionization near the wires and, as a result, the occurrence of discharge currents between them), transformer idling – up to 7%. Total losses range from 41% in the summer to 55% in the winter.Reference Korotoun1 In the EU loses at the transmission of electric power are low (only a few percent)2 because they use underground cables instead of ground towers with wires (but such cables are quite expensive themselves) and also when transmitting electricity over long distances a low current at high voltage are used. If the efficiency of a boiler, say, of the thermal power plant (it can be a coal, gas, or nuclear power plant) is 37%, then what is the efficiency of such plant for an energy consumer? This correlate with an estimation of American specialists, who point that up to 65% of energy, is lost in power plants.Reference Wirfs-Broc3 Besides, coal and gas power plants generate extra CO2 emissions, which results in a greenhouse effect.

There is another negative impact of the operation of nuclear power plants and thermal power plants on the Earth's climate. To cool the reactors and boilers of the plants and generate superheated steam (up to 600 °C), a huge amount of water is used, which is dumped into large bodies of water, increasing the degree of heating the atmosphere and negatively affecting all living in the reservoirs.

Moreover the cycle: coal, generating electricity, manufacturing machines for coal mining and its delivery to thermal power plants, shows that this thing in itself is not very effective for humanity. The problem of wind farms and solar power plants is that they cannot work without additional support of “the old power generation” (when the wind and/or sun are absent). Wind and solar energy is not really paying off (they need extra high tariffs). Moreover, modern wind farms negatively affect everything living in a radius of 6 km due to infrasound. And the vibrations of a windmill can threaten residences and other constructions.

New campaigns in power generation

Gasifiers

In 2009, EUREKA Agency (an association of publicly funded research institutions) in the European Union issued a policy document4 for the European Commission. In particular, it states: “Advanced gasification processes should be developed for power and hydrogen and/or syngas production using biomass-fired integrated gasification combined cycle turbine plants. Gasification needs to be demonstrated for small-scale, decentralised applications”. Our first model of a 50-kg processing gasifier won a big grant of the EUREKA agency in 2009. We developed proprietary and potentially disruptive next generation technologies, based on original research work of our team (Y. Zabulonov, V. Krasnoholovets, and others). Our awards: the "Most Promising Company" at the PwC Accelerator Expo in Luxembourg (21 March 2013) and World Green Design Award at the international Design Forum in Yangzhou, China (28 May 2013). Figure 1 shows the third and fourth versions of our gasifiers.

Figure 1. Our gasifiers of 2016 (a, which recycles 30 kg/h of waste) and of 2018 (b, which recycles 80 kg/h of waste).

We elaborated a technology for the production of small gasifiers several a couple of years ago. Gasifiers can work on municipal solid waste including plastic, organic matter, mule waste, biomass, livestock waste, etc. In other words, our gasifiers not only utilize waste, they in addition generate heat and are able to generate electricity. Such small size gasifiers can even stop at night and turn on in the morning, which will eliminate the generation of idle night energy. The gasifiers can be located in city blocks and the shoulder of heat and electricity supply will be minimal, and with it the energy losses will be very small. It is also a cluster: several gasifiers can be allocated at one point and if necessary more units can be used (e.g., in the winter time). About 100 million tonnes of carbon-containing household waste are generated annually in Europe. This energy raw material is enough to cover the annual electricity demand of Poland and Ukraine combined and an additional huge cogeneration heat will also be produced.

Small-scale gasifiers are the best orderlies that can completely clean the environment of household waste, plastic, poisonous organic matter while producing energy.

Moist raw materials (up to 70% humidity) and a two-stage combustion process make it possible to produce a synthetic gas at the first stage (a mix of CO and H2 in which almost half is hydrogen) and at the second stage, the syn-gas is combusted. A method of oxidative thermolysis and a plasma controller used in the gasifier is able to generate almost free additional energetic raw materials – hydrogen, which at the combustion supports a high temperature in the reaction chamber, from 1200 to 1700 °C, which additionally cleans the emissions.

The efficiency of small size gasifiers is 90%, which is 2.5–3 times of the efficiency of large boilers in coal, gas, and nuclear power plants (see, e.g., Refs. [Reference Korotoun1,Reference Wirfs-Broc3]). Small size gasifiers do not require water at the generation of heat and only a relatively small amount of water for cooling during generation of electricity (in the case when a steam turbine is used) and no extraneous cooling at all when using machines such as diesel generators. A typical industrial small size gasifier is shown in Fig. 2.

Figure 2. Design of an industrial gasifier (the area of the gasifier base, which will recycles 1 tonne per hour, is 10 sq m, the height is 2 m).

In rural areas, it is important to have the program of installation of small-scale gasifiers that will convert biomass available on the surface of the earth into a syn-gas. It is advisable to adjust a serial output of gasifiers (with a processing capacity of 50, 100, 200, 400, and 1,000 kg/h). Carbon processing depth is up to 99%; that is, it will be a waste-free disposal since slag in the volume of 1 or a little bit more percent can be used as an active additive in the construction industry (concrete blocks, roads). In the case when the raw material is grass or trees, the residual grass slag can be turned back into the fields.

High-energy grass (miscanthus, switchgrass, and so on) and/or shrubland trees (willow, poplar, and paulownia) can be grown, which yields an average of 20 tonnes of dry biomass per hectareReference Humentyk and Bondar5 a year. It is interesting that such young plantations are up to ten times more actively absorbing CO2 from the atmosphere than the adult forest. And accordingly, ten times more oxygen is released compared to the same area of an adult forest.

By converting biomass into energy using a gasifier, we will obtain the minimum 2.22 × 104 kWh (or 8 × 104 kJ/mol) of thermal energy from 1 ha. From 1 million hectares, this will be 22 billion kWh of thermal energy, or about 7.5 billion kWh of electric energy a year. The cost of energy generated by the gasifier is low. For example, today Ukraine generates 160 billion kWh of electricity annually (approximately 25–40% of this energy comes from nuclear power). Of this magnitude, about half is lost through inefficiencies, thermal losses and night-time generation. So, real consumption is at the level of about 80 billion kWh. That is, only using biomass grown on 10–15 million hectares of land, Ukraine is able to fully provide itself with electricity (compare with a similar analysis conducted in Ref. [Reference Song, Guziana, Mirmoshtaghi, Thorin and Yan6]). In total, 45 million hectares of land are used in the agricultural sector of Ukraine, which is 75% of its territory. Although 10–15 million hectares are enough for the agricultural sector of the country alone and the rest has to be planted with forest and energy vegetation.

Small size gasifiers will be able to substitute the state unified electrical grids for local sustainable networks with autonomous energy, which will allow the states to save about three times material resources (coal, natural gas, wood, straw, peat, etc.) generating the same energy needed for customers. Since raw materials in our case are almost biomass and only 10–15% are municipal solid waste (maybe plastic waste is only 5%), greenhouse gas emissions will be minimal; the additional load on nature will be caused only by CO2 emissions from recycled plastic. This additional value of CO2 can also be significantly utilized if we will widely use greenhouses in agriculture. Indeed, after all, exhaust from gasifiers can be sent directly to a local greenhouse, which will promote very active growth of plants with a significant reduction of water resources for irrigation (from our experiments, it follows that growing grass from grains for feeding cows and chickens in this way allows one to collect the annual harvest of everyday fresh grass from 1 ha of greenhouse the same as from 250 ha of open ground of a black soil field).

In rural areas, there is an opportunity to obtain biogas from agricultural waste. For example, 3000 m3 of daily agricultural waste can produce more than 4 million m3 of methane gas a year. For this purpose, anaerobic–aerobic technology should be used as the most rational, energy-saving, and nature-friendly method for the treatment of wastewater from plants processing agricultural products. The new integrated approach to environmentally friendly and energy-efficient organic waste treatment not only cleans wastewater and reuses water but also produces methane; hence, heat and electricity, and utilizing CO2 produces highly valuable disinfected organic fertilizers. In addition, this approach allows the greenhouse cultivation of large quantities of green fodder for domestic animals and poultry to be widely implemented, which will significantly save area for growing crops. In this approach, agricultural waste is recycled with a low greenhouse gas emissions, and in their majority biogenic elements are recycled back into the soil with organic fertilizers to reproduce its fertility.

We believe in the success of small gasifiers because in the past such a model of energy was already successfully realized in Ukraine in 1944–1964. After the second world war, the energy sector of Ukraine was based practically on hydroelectric plants and gasifiers that operated on coal, peat, wood, and straw. A few thousands of gasifiers with a capacity of 1 MW and much more with lower capacity were operating in Ukraine till 1964. That time the economy of Ukraine was practically the same as that of Germany, the UK, and France. However, this energy structure was destroyed in the first year of the Brezhnev era (1965): research institutes that designed gasifiers were closed, all gasifiers were cut into scrap metal, and a pipeline with natural gas was stretched from Siberia.

Torus electric motors

It is now known that more than 50% of the world's electricity is consumed by electric motors.7 All over the world, they use the model of electric motor proposed by Nicola Tesla 120 years ago. Nevertheless, so-called axial flux permanent magnet brushless machinesReference Binder8 begin to gradually conquer the market because they are being increasingly used in consumer electronics, instrumentation and automation system, clinical engineering, industrial electromechanical drives, automobile manufacturing industry, electric and hybrid electric vehicles, marine vessels and toys, electric aircrafts, and many other applications on larger scale. New applications have also emerged in distributed generation systems (wind turbine generators, high-speed micro turbine generators), miniature power supplies, flywheel energy storages, aircraft and rotorcraft actuators, missile fin actuators, and naval integrated motor-propellers (rim driven thrusters). The role of axial flux permanent magnet brushless machines is increasing especially in applications where integration of motors with other mechanical parts is imperative. This category of motors can also include torus (i.e., donut) electric motors (see, e.g., Refs. [Reference Caricchi, Chalmers, Crescimbmi and Spooner9–Reference Gieras, Wang and Kamper11]), though their technical parameters are still far from ideal.

In our understanding, a torus motor has to consist of a flat disk-shaped rotor and two torus-shaped stators placed on both sides of the rotor. It uses the most modern NdFeB and SmCo magnets, which in their technical characteristics are an order of magnitude superior to those currently used in electric motors. Instead of bearings, a magnetic suspension is used. Using two stators, the motor can reach 6,000 rpm. If one uses 20 twin stators and one rotor, which are found on the same axis, the engine will be able to reach 120,000 rpm. Such torus motors are characterized by small dimensions and reduced weight (power to weight ratio: 1 kW to roughly 1 kg only); they have increased power due to powerful magnets, magnetic suspension, and original design.

The discussed torus motor will be twice as efficient, that is, will consume twice less electricity to perform the same mechanical work and can be used as an energy storage device (say, during the night), like a flywheel. On the basis of this torus engine, it can be designed: pumps, compressors, blowers, cavitational installations, and generators. The torus pump is simultaneously a reversible machine: in one direction, it works like a pump and in the opposite – like an electricity generator.

Energy storage devices

To store energy in the form of compressed air or liquid, special vessels can be used. They can be made of a composite material based on basalt fiber threads in the form of an oil tank. Winding technologies are used. Such vessels never explode, they can only siphon. At the first stage, a pressure of 320 atmospheres can be used and in the future up to 1200 atmospheres. Such vessels can serve as energy storage devices in wind, river, and marine power plants (see below) but also in land transport: buses and trucks. For this, buses and trucks with a trailer are equipped with low and high-pressure vessels, as well as motor wheels. Compressed air drives the motor wheel; the vehicle rides and the compressed air enters the low pressure vessel. When the vehicle brakes, the air from the low pressure vessel enters the high-pressure vessel. Buses can travel 250–300 km in compressed air; trucks can cover twice the distance.

Using torus motors as generators rotating in a vacuum, we can outline inertial vacuum drives (which also known as so-called flywheel energy storage systems, or FES) of various power. When installed at energy generation facilities, all surplus day and night energy can be transferred to FES; the flywheel spins up and during peak hours it will give out additional electricity.

The torus engine makes it possible to design a new type of air transport – flying platforms. A miniature copy of such a flying platform is an unmanned aerial octocopter. Torus motors can store energy in the form of torque. Therefore, FES systems with a speed of 120–240 thousand revolutions per minute, installed in the amount of 500–2000 units on a special platform, that is, a large aerodyne like a huge flying saucer, can transport several thousand tons of cargo over the air to a distance of 10,000 km or more. In order to “energize” such a platform with energy, it is enough to connect it to the electric network (this can be done at owing to a cheaper night tariff) and when the required number of revolutions is reached, the platform is ready to set off. It should be borne in mind that for such flying systems, the airports will require areas with unloading–loading of goods and places with electric charging. It is enough, say, in Tokyo to load 2000 cars on the platform and after a few hours to land at a cargo airport of any city and begin to unload cars, load other goods, and charge the platform's engines. Not expensive, fast, environmentally friendly. The main thing is that one can start implementing this project in the next 3–5 years.

Marine wave power plant

Morsy El-GoharyReference Morsy El-Gohary12 overviews the most effective types of marine power plants, though he consider such plants as operating on clean fuel, and first of all, this is the hydrogen as fuel for marine internal combustion engine, gas turbines, and fuel cells. In particular, review papersReference Clément, McCullen, Falcão, Fiorentino, Gardner, Hammarlund and Pontes13–Reference Cascajo, García, Quiles, Correcher and Morant15 discuss marine and tide wave stations as a possible perspective of energy generation from the sea; nevertheless, these works do not bring an idea of really an industrial powerful plant.

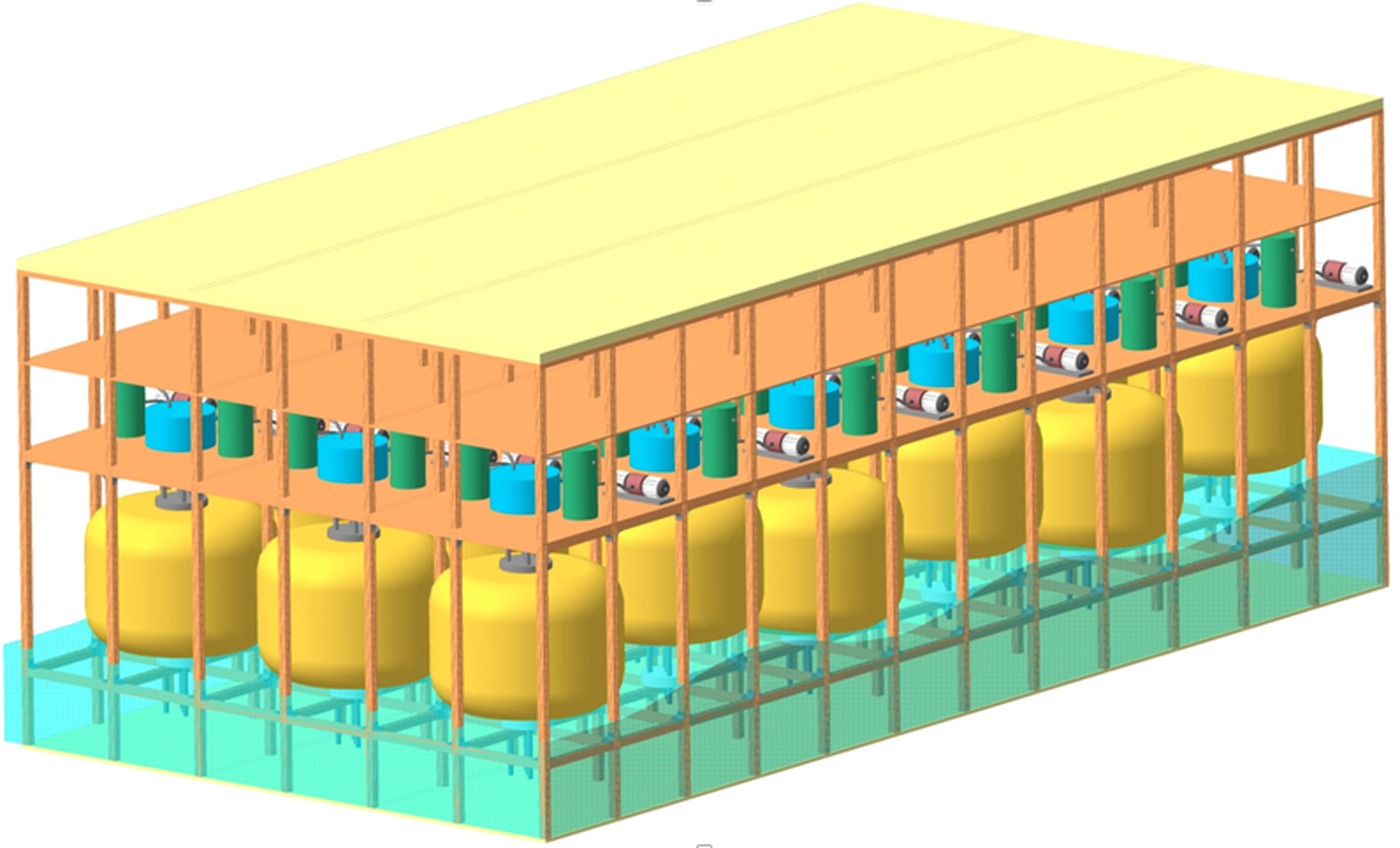

In our view, the plant for the production of energy from sea waves should be an island consisting of many cells each of which has the same size 6 m × 6 m installed at a depth of 12–30 m in a short distance from the shore in places of continuous waves. A capacity of such a unit is estimated as 30 kW. Initially, marine waves pre-accumulate their energy in high-pressure tanks with compressed air. Electricity can be generated by using a jet of air that will rotate the impeller of the torus motor, which in the present case acts as a generator.

The plant can include a number of the cells, for example, from 4 to 8000 cells (Fig. 3). Then, the electric power generated by such a plant can vary, respectively, from 120 kW to 250 MW and above. The plant can generate electricity and also produce technical and drinking water. During peak hours, it could produce additional electricity, up to 1.5 times above the declared capacity due to the accumulated energy and additional generators installed in the cells. The plant is absolutely environmentally friendly.

Figure 3. Marine wave power plant.

Above the engine room the flat surface can used to install hotels, beaches, indoor (separated from the sea) and outdoor (fenced) pools, a pier, large aquariums, solar panels, wind power plants, navigation and communication equipment and stations, greenhouses for growing food, industrial fish farming and other marine life, lighthouses, communication towers, seismic sensors and tsunami sensors, modules for refueling ships, both with electricity and fresh water and other resources, platforms for landing compact aircraft and mooring ships. Our estimates show that the cost of electricity generated by such a marine wave plant will not exceed € 0.01.

River power plants

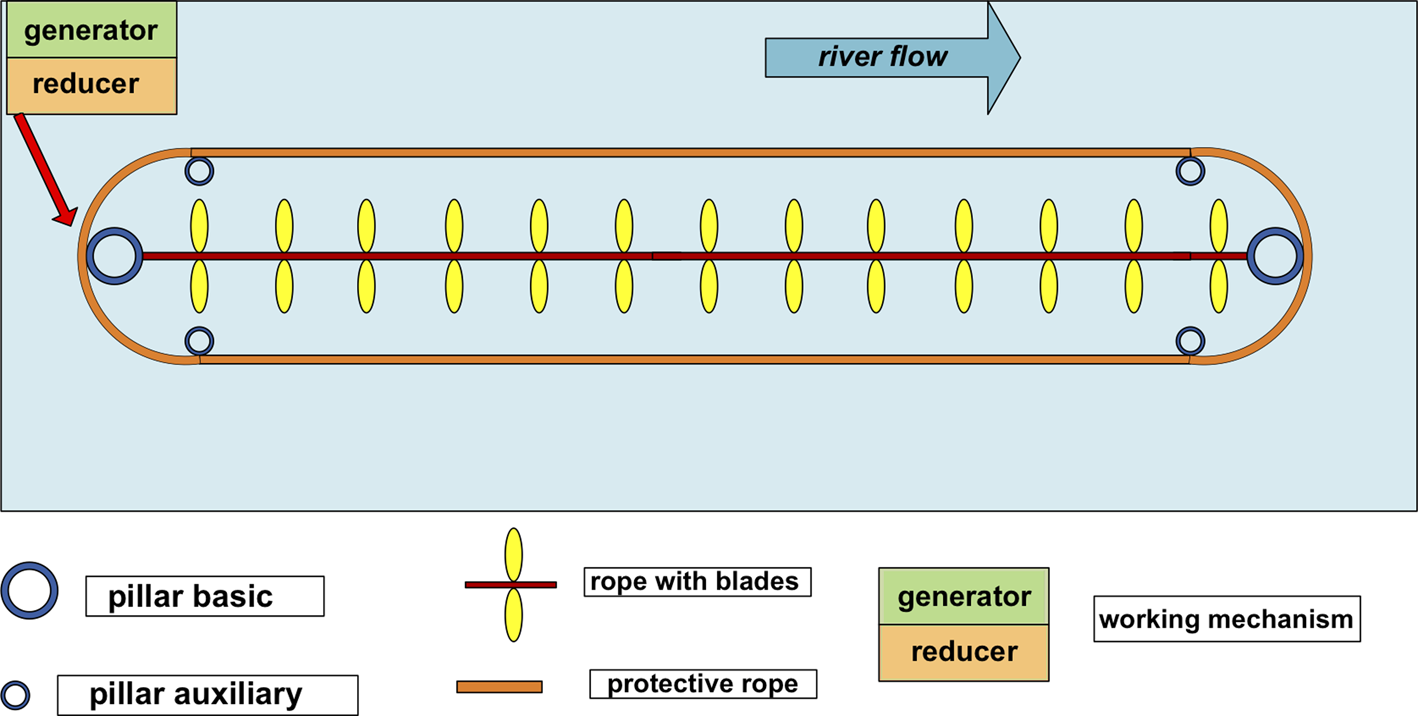

Dams are not needed, a river power plant can be installed in a river and canal (Fig. 4). It is sufficient only that the flow velocity exceeds 1 m/s and the depth at the place of installation of the turbine is not less than 1.5–2 m. First, the main pillars are installed, to which the main cable with blades is attached. Then, auxiliary pillars with breakaway cables are placed. On the first pillar, a cab platform with a working mechanism is mounted. Energy storage vessels and the torus motors functioning as generators are installed on the shore. A multiple river power plants can be mounted in parallel or in series. Such river electricity is not subsidized either. Power generated by one turbine can be graded from 30 to 120 kWh.

Figure 4. River power plant.

Wind power plants

GarveyReference Garvey16 writes that one possible way to integrate energy storage with wind power is to use the wind turbines directly to pump water uphill. Then, water will fall down rotating turbines. Nevertheless, this approach is quite complicated and that is why he believes the only other sensible option for integrating wind with energy storage is gas compression. This is the way we wish to follow.

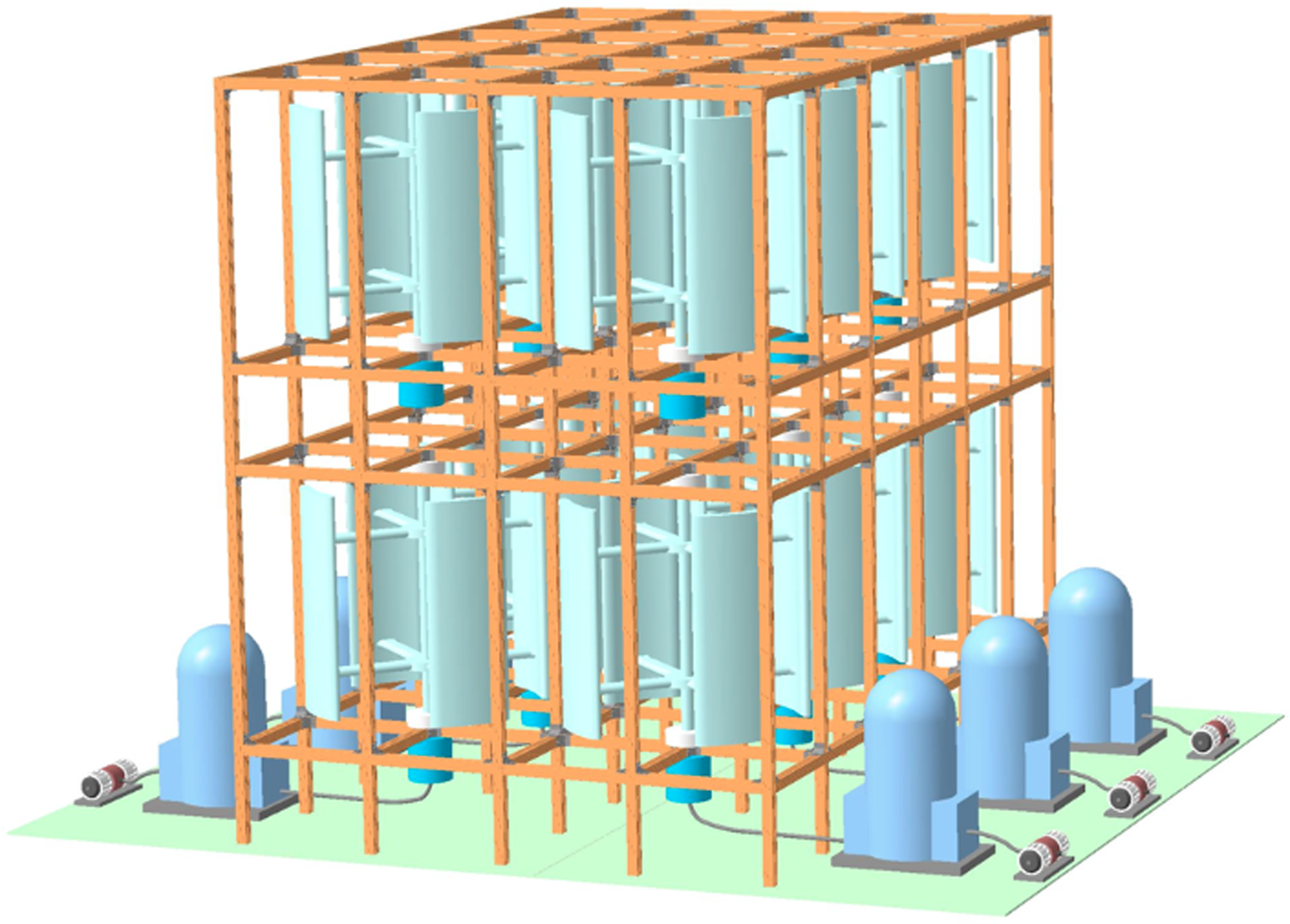

A wind turbine installed on a mast with a height of 8–12 m can work even at a small wind, including weak turbulent flows from 0.5 and higher m/s, but it does not turn the generator directly, like is the case of all modern windmills. Blades are mounted on a vertical axis, which prevents the spread of infrasound in the environment. The wind turbine will rotate a torus compressor (or pump), which compressed the air into a high-pressure vessel. So, wind energy can be pre-accumulated. Such vessels can store the energy for a long time. One can then generate electricity at times of consumption by using a jet of air that will rotate the impeller of the torus generator. Thus, energy with the parameters specified is transferred to the general electric grid or directly to the consumer. The plant can operate in the mode of return and accumulation at the same time. Such wind energy systems can be installed in several rows along the length, width, and height. Due to compressed air, they can give off additional heat in a small capacity.

This is where we come to a new type of wind farms: pre-accumulation can significantly save costs because in this case idle wind farms will be absent – the generated electricity will not go into the ground, as it is now at night.

In such a manner, the main aspects of wind energy in the nearest future are (i) pre-accumulation of wind energy in compressed air and (ii) availability of electric torus generators that will effectively convert the kinetic energy of air jet into electricity. This approach to wind energy generation will not require subsidies (Fig. 5).

Figure 5. Wind power plant. Vessels with the compressed air are located on the ground around the turbines. Torus generators are connected to the vessels.

Gasifiers, solar panels, wind power, marine wave power, and river power make it possible to create locally forceful power generation systems for settlements without introducing common grids and all the named approaches of the energy generation is easy to automate.

Cavitator heater

It is advisable to heat premises and houses with the help of electric boilers that will use the above-mentioned new torus electric motors because only such motor with a large power reserve is able to push water through the cavitator, such that the water will heat up in a short time. The boiler function using the torus motor and cavitator will be the most optimal solution for space heating as the average price paid by the owner of the premises can be reduced to 1 euro for 20–25 m2/month.

The latest trends in energy generation and savings

An air-conditioner and refrigerator

An ideal refrigerator and air-conditioner are described by the theoretical coefficient of performance

although, in practice, this ratio is 2–3 times lower. A similar situation is for a heat pump (also for the air-conditioner working in a reverse mode), which in an ideal case is characterized by its own coefficient of performance

though, realistically, it is at least two times smaller.

The air-conditioners and refrigerators are functioning on the refrigerant and the compressor. All the refrigerants like the chlorofluorocarbons and similar cause ozone depletion, and the other group containing hydrofluorocarbons bring about the super-greenhouse effect. These active gases running under high pressure in the cooling system seep into the air due to micro cracks in the tubes and thus gradually demolish the atmosphere. The control system in modern air conditioners and refrigerators is quite complex and has to support the required value of ΔT between the evaporator and condenser of the refrigerant and also regulate the revolution of the compressor motor. So, there are loses in the compressor, throttle, and heat exchanger. All this reduces the theoretical coefficients of performance (1) and (2). In addition, the weakness of this technology is its cumbersomeness.

Equipment used in cooling systems express the cooling system efficiency in terms like EER (Energy Efficiency Ratio) and also SEER (Seasonal Energy Efficiency Ratio), which are aimed to approach the ideal coefficients (1) and (2). The developers are focusing on reducing leaks and therefore emissions of refrigerants into the atmosphere, and also cutting the energy consumption of air-conditioners and refrigerators.

On the other hand, there is the other approach for cooling/heating based on the Peltier effect at which a heat flux is created at the junction of two different types of materials. A Peltier cooler, or thermoelectric cooler (TEC), transfers heat from one side of the device to the other, with consumption of electrical energy, depending on the direction of the current.

A Peltier cooler does not have a vapor-refrigerant, circulating liquid, and moving parts; it has a very long life, invulnerability to leaks, small size, and flexible shape. Nevertheless, modern semiconductor solid-state Peltier coolers have severe disadvantages: they have very limited cooling capacity, poor power efficiency, and high cost.

However, the named shortcomings of the Peltier solid-state coolers are eliminated in thin-film technology. Figure 6 exhibits a true thin-film cooler acting on the Peltier effect (the technology was elaborated by Dr. Valery Rodionov, though the results unpublished). The thin film is a film semiconductor in which the classical rules of thermoelectricity and photoelectricity typical for monocrystals are maintained. A cooling capacity can be multiplied by folding the film many times, which makes it possible to reach temperatures obtained in refrigerators and at the output of air-conditioners. The contact area of the connected films is the most important parameter because it regulates the current. The efficiency of such a thermoelectric device depends on additional inclusion in the matrix material of certain impurities with deep levels and it can reach 50%.Reference Iordanishvili17 The production cost of the thin film is low (a few kilometres can be produced per day). So, the development is almost ready for industrial implementation.

Figure 6. Cooler operating on thin film Peltier effect.

Pyramid power

For individual farmers or homes, it will be possible to develop autonomous electricity generation technology using a pyramid tower. In the pyramid, resonance phenomena take place – excitation of the earth's inerton field.Reference Krasnoholovets and Byckov18 If one enters a certain electrical circuit in such a field, the pyramid intensifies the movement of electrons.Reference Grandics19 From our current experiments, it follows that the energy of electron motion in the pyramid field can be increased around eight times. This means that by entering 1 kW of power into the scheme, it will be possible to remove output 5–7 kW. The study is continued and the first results obtained are promising.

Final remarks

The above-mentioned areas of technology development point to the importance of local grids (for the village, district, and city), which in the future should substitute for the current common electricity grids. We offer such generation systems that can be switched on/off at the right time. Such actions are not possible in large power generation plants. Reorientation to local grids will provide significant savings in both material and monetary resources. This step adds additional stability and resilience to the country's economy.

Recent studies demonstrate that hydrogen gas combustion plants may appear widely in the future (see, e.g., Ref. [20]). Such plants can be placed near methane gas deposits. In a well with some technology that involves the use of iron as a catalyst, methane is stripped of carbon and pure hydrogen is released to the surface, which will be burned in hydrogen furnaces. Hydrogen engineering work has already begun. After all, the emissions into the atmosphere will be only H2O.

A wastewater treatment process allows the release of hydrogen and such hydrogen can be used as a clean energy raw material.

If all of the projects listed in this paper will be run, we will be able to gradually close all nuclear power plants, as well as large thermal coal and gas ones. The biomass, household waste, the energy of wind, rivers and seas, and the sun available at the surface of the earth, and hydrogen accessible at sea and underground will be sufficient to generate the electricity and heat needed for the country.

The proposed energy model of the country's development will allow the country to solve the problem of unemployment. A number of small companies will appear that will work in the area of energy. In principle, several million people could be able to find the job in the proposed energy model. People will work in the agriculture area growing energetic plants, will transport biomass, burn biomass in gasifiers, and also will be involved in service work related to wind farms and river turbines.

Finally, let us dwell on the newest direction in energy, which physics has begun to probe in the last two decades. It is a phenomenon of so-called cold nuclear fusion, or low-energy nuclear reactions. This trend continues to be explored by both independent researchers and respected scientific and technical laboratories. But the situation is still unclear.

Review workReference Berlinguette, Chiang, Munday, Schenkel, Fork, Koningstein and Trevithick21 notes that, currently, the academic community has rather a negative judgement regarding the possibility of cold fusion. Nevertheless, the authors describe their own efforts, which could provide new insights into highly hydride metals and low-energy nuclear reactions because still a number of underexplored parameters remain. In one more recent work,Reference Kálmán and Keszthelyi22 the researchers theoretically study exothermal nuclear reactions, which forbidden due to Coulomb repulsion and show that any perturbation may mix states with small but finite amplitude to the initial state resulting in finite cross section (and rate) of the originally forbidden nuclear reaction in the ɛ → 0 limit.

On the other hand, the researchers exploring cold fusion still work in the framework of conventional quantum mechanics, which was derived at the atom size, that is, ~10–10 m, though nuclear reactions occur at a distance of about 10–15 m. But what is beyond the quantum mechanical formalism? This problem was studied in detail in a book of one of the co-authors,Reference Krasnoholovets23 which revealed the primary knowledge base of physical science at Planck's scale ~10–35 m. Only research within a paradigm that discloses the first principles of the constitution of real physical space will allow us to choose the right direction in understanding the ways of finding controlled low-energy nuclear reactions.

In fact, at our experimental and theoretical study,Reference Krasnoholovets, Zabulonov and Zolkin24 we found that at some peculiar conditions a proton could couple with an electron absorbing an inerton cloud of the nearest heavy atom, which resulted in the creation of a quite stable subhydrogen whose size could only be about 1 fm. Similarly, a subhelium atom was generated and it was predicted the possibility of heavier subatoms with the nuclear size of around 1 nm. Such tiny subatoms are neutral and, hence, can easy to overcome the Coulomb barrier of any conventional atom approaching its nucleus, which may result in the merger of two nuclei with possible further division into two other nuclei. Indeed, we revealed significant mutations in iron, such that emerged the following elements: Co, Ni, Ca, Hf, and Cs [Reference Krasnoholovets23, pp. 314–327]. Such reactions can take place without the emission of gamma quanta and neutrons but with the release of excess inertons. Can such inertons be harnessed to give a useful output of kinetic energy or additional electric current?

It seems the European Organization for Nuclear Research (CERN), which is a large-scale research facility, might be interested to study new nuclear physics, which is manifested at moderate energy values.