Published online by Cambridge University Press: 09 September 2020

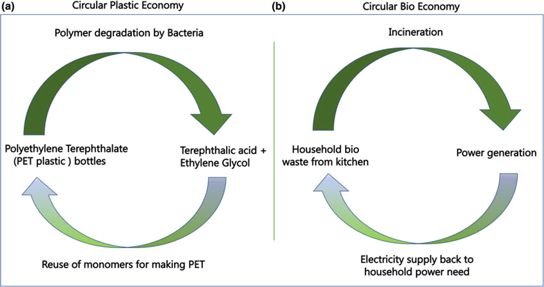

The circular economy aspects of PET (polyethylene terephthalate) waste conversion into value-added products are discussed concerning different governmental policies and industrial protocol for plastic degradation.

The use of microbial enzymes such as PET hydrolase is discussed regarding PET (polyethylene terephthalate) degradation.

The primary purpose of this perspective is a critical analysis of the correlation of the current state-of-the-art rising circular economy platform enacted across the world with close looping of PET (polyethylene terephthalate)-based plastic polymer disposal and sustainable recycling and upcycling technology. The goal of the upcycling process is to get the low-cost value-added monomer than those obtained from the hydrocarbon industry from the sustainability prospect. A summary of the circular bio-economic opportunities has also been described. Next, how the PET hydrolase enzyme degrades the PET plastic is discussed. It is followed by an additional overview of the effect of the mutant enzyme for converting 90% of plastics into the terephthalate monomer. A site-directed mutagenesis procedure obtains this particular mutant enzyme. The diversity of different microbial organism for producing PET hydrolase enzyme is finally discussed with a suggested outlook of the circular economy goal from the viewpoint of plastic degradation objectives soon.