Published online by Cambridge University Press: 25 April 2019

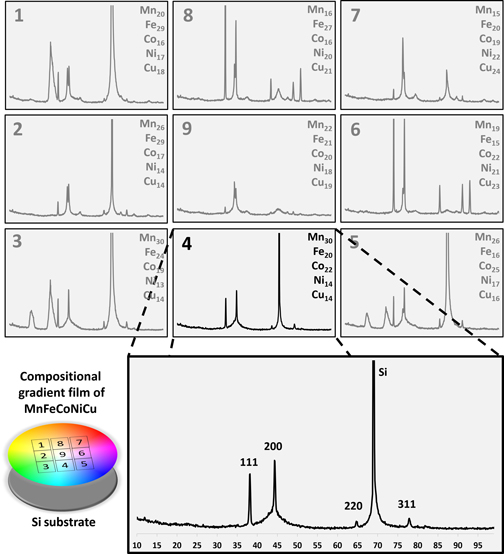

To identify new face centered cubic high entropy alloys (HEAs), MnFeCoNiCu thin film samples were prepared by simultaneous magnetron sputtering of elements onto Si wafers. This sputtering arrangement yielded compositional gradients in the samples. The films exhibited regions with different phases, some of which were single-phase and non-equiatomic. To screen the crystal structure and composition across film samples, multiple characterization techniques were used: scanning electron microscopy, focused ion beam, energy-dispersive x-ray spectroscopy, x-ray diffraction, and electron backscattered diffraction analysis. Using this combinatorial method, candidate single-phase HEAs were identified and then successfully arc-melted in bulk form, followed by thermomechanical processing.