Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Oña Chuquimarca, Samara

Ayala-Ruano, Sebastián

Goossens, Jonas

Pauwels, Laurens

Goossens, Alain

Leon-Reyes, Antonio

and

Ángel Méndez, Miguel

2020.

The Molecular Basis of JAZ-MYC Coupling, a Protein-Protein Interface Essential for Plant Response to Stressors.

Frontiers in Plant Science,

Vol. 11,

Issue. ,

Vyshegorodtseva, E. V.

Matskan, P. A.

and

Mamontov, G. V.

2020.

Formation of hierarchical MIL-100(Fe)diatomite composite.

Vol. 2304,

Issue. ,

p.

040018.

Tan, Jinwang

Cannon, Andrew

and

Ryan, Emily

2020.

Simulating dendrite growth in lithium batteries under cycling conditions.

Journal of Power Sources,

Vol. 463,

Issue. ,

p.

228187.

Cannon, Andrew

and

Ryan, Emily M.

2021.

Characterizing the Microstructure of Separators in Lithium Batteries and Their Effects on Dendritic Growth.

ACS Applied Energy Materials,

Vol. 4,

Issue. 8,

p.

7848.

Pollard, Zoe A.

Cannon, Andrew

Ryan, Emily M.

and

Goldfarb, Jillian L.

2022.

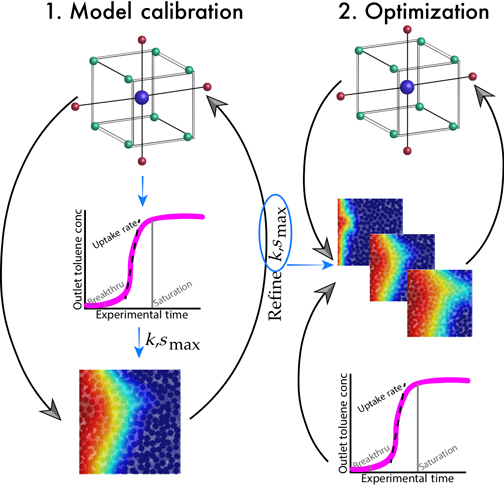

Capturing the effects of particle heterogeneity on adsorption in a fixed bed.

AIChE Journal,

Vol. 68,

Issue. 4,

Evdokimova, E. V.

Matskan, P. A.

and

Mamontov, G. V.

2022.

MIL-100(Fe)/Diatomite Composite with Hierarchical Porous Structure for Sorption of Volatile Organic Compounds.

Russian Journal of Physical Chemistry A,

Vol. 96,

Issue. 1,

p.

171.

Schofield, Parker

Luo, Yuting

Zhang, Delin

Zaheer, Wasif

Santos, David

Agbeworvi, George

Ponis, John D.

Handy, Joseph V.

Andrews, Justin L.

Braham, Erick J.

Balakrishna, Ananya Renuka

and

Banerjee, Sarbajit

2022.

Doping-Induced Pre-Transformation to Extend Solid-Solution Regimes in Li-Ion Batteries.

ACS Energy Letters,

Vol. 7,

Issue. 10,

p.

3286.

Ryan, Emily

Roshandelpoor, Athar

Pollard, Zoe

Goldfarb, Jillian L.

and

Vakili, Pirooz

2023.

Prospective on methods of design of experiments for limited data scenarios in materials design and engineering.

MRS Communications,

Vol. 13,

Issue. 6,

p.

1087.

Pollard, Zoe A.

Roshandelpoor, Athar

Vakili, Pirooz

Ryan, Emily

and

Goldfarb, Jillian L.

2023.

Towards tunable polymer foam fabrication: A case study to advance green materials development in limited data scenarios.

AIChE Journal,

Vol. 69,

Issue. 4,

Amna, Riffat

and

Alhassan, Saeed M.

2024.

A Comprehensive Exploration of Polysulfides, From Synthesis Techniques to Diverse Applications and Future Frontiers.

ACS Applied Polymer Materials,

Vol. 6,

Issue. 8,

p.

4350.