Emerging industrial, transportation, and biomedical applications require lightweight materials that exhibit high strength and ductility. Titanium alloys offer many of these qualities and, as a result, meet many of the demands of bone implants and hypersonic engines. However, many of these emerging applications require equivalent mechanical performance at very high temperatures. Unfortunately, active slip systems, kinetics of dislocation movement, and the overall plastic response of metals at elevated temperatures noticeably vary from that at ambient temperature. In an effort to assess deformation mechanisms of high-strength alloys at high temperatures, mechanical tests must be conducted in thermally controlled environments relevant to the operating conditions, and these need to be accompanied by crystallographic measurements. By their very nature, these approaches are complex and introduce further variables into the experiment.

Recent research efforts have brought forth a new method that relies on high-energy x-ray diffraction microscopy (HEDM) instead of exhaustive single- crystal testing to assess the strengths of slip systems in various titanium alloys. These measurements streamline the data acquisition and analysis and allow high-temperature measurements to be performed. Darren C. Pagan of the Cornell High Energy Synchrotron Source (CHESS) analyzed the slip system responses in a Ti-7Al alloy at 355°C. Together with his colleagues J.Y. Peter Ko of CHESS, Joel V. Bernier of Lawrence Livermore National Laboratory, Todd J. Turner and Paul A. Shade of the Air Force Research Laboratory, and Basil Blank of PulseRay, Inc., Pagan published the findings in a recent issue of Scripta Materialia (doi:10.1016/j.scriptamat.2017.08.029).

“With the high-energy x-ray techniques available at synchrotron x-ray facilities like CHESS, we are now able to probe material deformation in metals at the size scale at which material failure initiates,” Pagan says. “These microscale mechanical data are extremely valuable for developing and validating the mechanical models that can be used to design new high-performance components.”

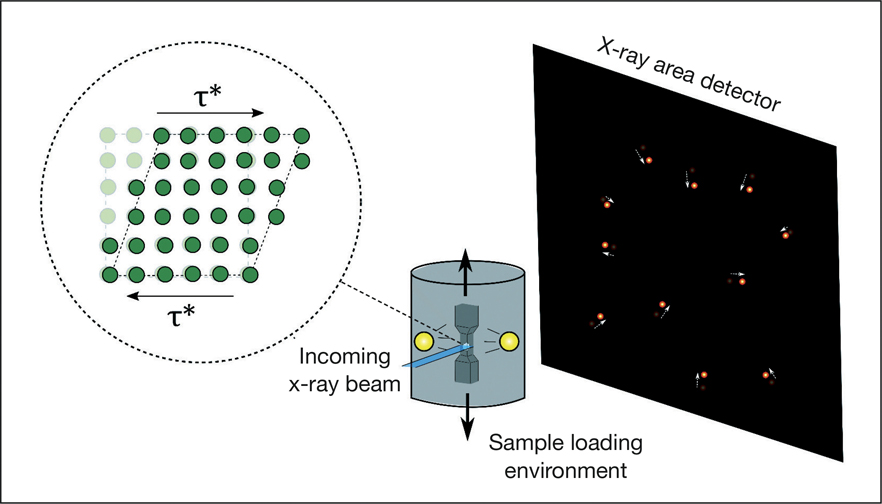

Using new high-energy x-ray techniques, deformation at the microscale can be probed deep within the bulk of deforming engineering alloys even in complex sample environments. From measured shifts in diffraction peak positions, the shear stresses (τ*) required to permanently shift atomic planes relative to one another in individual deforming crystals comprising the samples can be deduced. Image Credit: Darren C. Pagan.

The study analyzed a model titanium-aluminum alloy (7.02 wt%) with small amounts of oxygen and iron additives that is very similar to the α-phase of the workhorse titanium alloy, Ti-6Al-4V. The x-ray diffraction data, which were collected at CHESS, were measured in both near-field and far-field detector configurations. While the former was used to reconstruct the morphologies of the grains, the latter derived grain orientations and elastic strain tensors. As the temperature increased in the sample enclosure, the instrument’s load frame strained the sample and the evolution of grain orientations and strains was tracked.

The researchers’ analysis of the derived data compared the responses of four different slip systems during deformation on basal, prismatic, and pyramidal atomic planes. The basal system, in particular, exhibited the most significant strength drop (from 110 to 98 MPa) during deformation under high temperatures. This behavior differed from similar stress–strain relationships at ambient conditions, which involved softening (lowering of material strength) with deformation of both basal and prismatic slip systems. Interestingly, high temperatures reduced the magnitude of softening of the basal system. This effect was attributed to reduced barrier energies for dislocations to cut through ordered precipitates and, subsequently, lower overall stress. Finally, stress–strain analyses of specific slip systems found that temperature reduced the degree of strain hardening of one of the pyramidal slip systems at 355°C relative to what was observed at room temperature.

This novel in situ approach has deconvoluted and clarified information about a complicated mechanical system. Typical high-temperature measurements do not allow for optical microscopy or precise (and often time-consuming) crystallographic analysis that is needed for analysis of every possible deformation system, and the collaborative efforts by Pagan and his colleagues have found a facile quantitative workaround. As metal alloys find new uses in high-temperature applications, techniques like these can properly assess their deformation mechanisms, strength, and reliability under required extreme operating conditions.