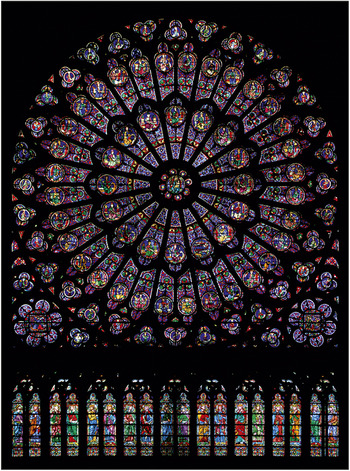

People often reference cathedral windows constructed during medieval times, found in places like Notre Dame in Paris and Westminster Abbey in London, when they want to provide an example of glass flowing at room temperature. Glasses in medieval cathedral windows are 1015 times less viscous than initially calculated, but glass still only flows at a rate of 1 nm over 1 billion years. These results, published recently in the Journal of the American Ceramic Society (doi:10.1111/jace.15092) by John Mauro of The Pennsylvania State University, will allow manufacturers to improve glass substrates used in high-resolution displays.

A glass is a nonequilibrium material. Besides being dependent on its current physical state, the properties of a glass are heavily influenced by its thermal history, which describes how quickly or slowly a glass was annealed. “If you have a glass that’s cooled more quickly, you can end up with a glass with very different properties compared to a glass that’s cooled more slowly,” Mauro says. The atoms in a glass are also constantly trying to reorganize by relaxing toward a more thermodynamically favorable arrangement, so over time the glass will change shape. At room temperature, these miniscule changes are beyond detection in even the most advanced experimental measurements currently available.

These medieval cathedral stained-glass windows are noticeably thicker at the bottom than the top. Research performed on modern glass compositions almost 20 years ago showed (see American Journal of Physics doi:10.1119/1.19026) that the manufacturing methods used in medieval times are actually responsible for this thickness gradient, countering the belief that glass flows noticeably over centuries. This older study, however, did not explore glasses with the same composition as those used in medieval buildings, or consider how different thermal histories affected the room-temperature viscosity. Redoing calculations using a model that includes these physical properties could significantly change the theoretical room-temperature viscosity.

Having developed a model of glass viscosity that took both the thermal history and composition of the glass into account (see Physical Review B doi:10.1103/PhysRevB.80.094204), Mauro and co-author Xiaoju Guo at Corning Incorporated calculated the viscosity for the specific glass mixture used in Westminster Abbey. Their results revealed that the viscosity of such glass was actually 16 orders of magnitude smaller than previously thought. To confirm the model’s validity, Ozgur Gulbiten, a researcher at Corning, fabricated a sample with the same composition of the glass in cathedral windows. Guilbiten measured the sample’s viscosity up to a value of 1018 Pa s—a heroic meas-urement that took tremendous patience, according to Mauro. Low viscosity confirmed, co-author Olus Boratav at Corning then calculated the room-temperature flow rate for a number of potential thermal histories, where this allowed him to account for the range of possible annealing conditions used by medieval glassmakers. While variations in the thermal history could change the flow rate by orders of magnitude, the glass “is not flowing at any perceptible level at room temperature, even over billions of years,” Mauro says.

Example of medieval glass seen in the south rose window of Notre Dame, Paris. Built in 1260 AD.

These results go beyond an academic demonstration to settle an age-old myth. “The ability to correctly model glass relaxation has some very important consequences for the manufacturing of high-definition displays,” says Mathieu Bauchy, a professor at the University of California, Los Angeles, who was not involved in the present study. Many layers of glass are fused together to create modern displays for computers or televisions. Manufacturers must heat the glass panels, which act as substrates, to place the electronics that form the pixels. As the definition in these displays increases, the size of the pixels decreases. Microscopic changes in the dimensions of the glass due to relaxation at high temperatures “could lead to misalignment of the pixels, and the display would not be functional,” according to Mauro.

In the field of glass relaxation for high-resolution displays, the applications for a composition-dependent model are abundant. Being able to predict and control the relaxation of glass by tailoring the composition or thermal history could lead to the development of better substrates in future displays. Mauro says he “hope[s] that people in the field will use this model to look at the dynamics of many other glass compositions, both for industrial purposes as well as academic exploration.”