Rare-earth aluminas have excellent thermomechanical properties for high-energy laser applications, but it has been challenging to create these bulk ceramics with high optical performance. Using a nanoscale-focused processing strategy, University of California, San Diego (UC-San Diego) researchers have now succeeded in observing optical gain in rare-earth-doped polycrystalline alumina. As reported in a recent issue of Light: Science & Applications (doi:10.1038/s41377-018-0023-z), the material has thermal conductivity superior to existing solid-state laser gain media and suggests a path toward broadening the palette of gain materials.

“One of the main problems with solid-state lasers is thermal management,” according to Javier Garay, the senior scientist behind this research. When pumped, gain materials produce heat that degrades the beam quality and, in extreme cases, the crystal can crack. “If we can improve the thermal conductivity of the gain material, then we can really get more power out for the same cooling and pumping configuration,” Garay says.

Polycrystalline alumina (Al2O3) has high thermal-shock resistance and fracture strength, but there are two significant obstacles to its use as a gain medium. Unlike yttrium aluminum garnet (YAG, Y3Al5O12) and other cubic gain materials, Al2O3 has a hexagonal crystal structure. This results in optical anisotropies that lead to scattering and reduce the material’s optical quality. Additionally, rare-earth ions have solubility in Al2O3 that is below the concentration required for the material to be sufficiently optically active.

In a key insight, the UC-San Diego research team realized that both obstacles could be addressed by reducing the grain size of the Al2O3 crystals.

Most of the scattering caused by the optical anisotropies in Al2O3 crystals occurs at grain interfaces. Instead of increasing the grain size to reduce the number of interfaces—which is a more common approach in this situation—the research team reduced the grain size to below the wavelength of the pumped and emitted light. As the grain size decreases, the scattering efficiency decreases. Using grains on this scale reduces the optical losses enough to make gain possible, Garay says.

Grain boundaries are also relevant to rare-earth solubility. Doped rare-earth ions tend to accumulate at grain boundaries rather than entering the Al2O3 crystal grains, although some do enter. When grain size is reduced, the volume fraction of boundary space increases. As a result, the researchers found that rare-earth dopants—in this case neodymium (Nd) ions—can spread out enough to reach the critical concentration required for gain if the grain size is sufficiently reduced.

The team established the range of grain sizes sufficient for gain from the relationships between grain geometry, dopant concentration, and average distance between ions. Then, the team experimented with processing techniques. The optimum grain size and concentration resulted when a pressurized mixture of alumina and neodymium powders was rapidly heated at a rate of 300°C per minute up to a temperature of 1260°C, held at that temperature for five minutes, and then rapidly cooled at the same rate. The high temperature increased the solubility of neodymium ions while the rapid cooling rate froze them in place, Garay says. The rapid heating rate kept the grain size to a minimum.

After characterizing their Nd:Al2O3 samples using x-ray diffraction measurements, electron microscopy, and optical spectroscopy to confirm the atomic structure and the presence of optically active neodymium ions in the material, the research team optically pumped the material with infrared light (806 nm). In response, Nd:Al2O3 emitted amplified light at 1064 nm, revealing net positive gain.

The new material displays thermal shock resistance that is 24 times that of the commonly used gain medium Nd:YAG, as well as a broader photoluminescent range that suggests tunability. Furthermore, Garay says, the result is extendable to other systems. This is not just the development of one new material per se, he says, but a demonstration of the fundamental physics behind leveraging length scales to design a more diverse group of optical materials.

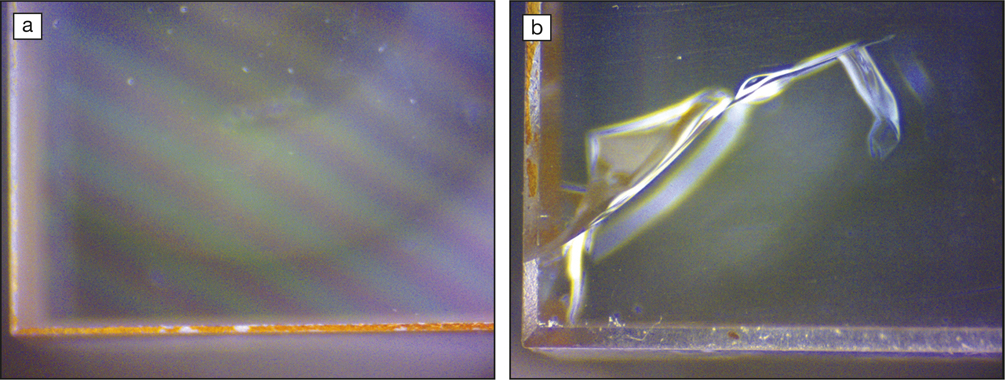

(a) Neodymium alumina shows no signs of cracking at 40 W applied optical pumping at 808 nm, while (b) neodymium YAG (Y3Al5O12) cracks at 25 W. Image courtesy of Elias Penilla, University of California, San Diego.

Turning the material into a working laser is likely to be a significant engineering and materials challenge. “It was proved in the 1990s that cubic-type ceramics would be a promising laser material, but today there are only a few researchers who can fabricate high-quality materials,” cautions Akio Ikesue, an expert in ceramic lasers from the Japanese company World Lab Co. According to Ikesue, achieving laser oscillation in a hexagon system material requires overcoming challenges in efficiency, fluorescence lifetime, scattering loss, and optical homogeneity. “From here, it will be the launch of true pioneering work,” he says.