Thin-film solar cells are currently prepared on temperature-resistant substrates due to the relatively high temperatures required for their fabrication. For this reason, they have been traditionally formed on thick silicon wafers or glass. The weight and rigidity of both these types of substrates greatly limit the range of applications of these solar cells in terms of portability, and also impedes their price for the end user. While thinner, flexible substrates are being explored to replace silicon during the fabrication process, they still need to be temperature-resistant. To dissociate the problem of the high-temperature deposition of the photovoltaic layers from the versatility required for commercialization, C.H. Lee from Stanford University, D.R. Kim from Hanyang University, N. William from the US National Renewable Energy Laboratory, and their colleagues recently introduced a way to efficiently transfer amorphous silicon thin-film solar cells from the fabrication substrate onto a variety of different substrates, including glass, paper, and plastic.

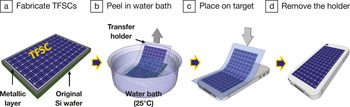

This technology is akin to transfer stickers favored by children. The thin-film solar cell is initially fabricated on a silicon substrate, and is then transferred onto a flexible intermediate transfer holder made of thermal release tape before being attached on the end substrate. Finally, the intermediate is removed by gentle heating (90°C). As described in the December 2012 issue of Nature’s Scientific Reports (DOI: 10.1038/srep01000,) the key element of the transfer process is a 300-nm layer of nickel deposited between the silicon substrate and the actual solar cell. Once the solar cell is ready and tested, the transfer holder is attached on top and the covered solar cell is placed in a water bath at room temperature. The nickel layer unbinds from the silicon surface, thus separating the solar cell from its heavy fabrication substrate, as shown in the figure. The solar cell can then be placed onto a variety of end substrates.

The “peel-and-stick” process to transfer thin-film solar cells to the end substrate. TFSC is thin-film solar cell. Reproduced with permission from Sci. Rep. DOI: 10.1038/srep01000. © 2012 Macmillan Publishers Ltd.

Very importantly, the researchers show that the solar cells do not lose efficiency subsequent to the transfer process and that bending of the transferred thin-film solar cells does not degrade the photovoltaic performances.