In the quest for zero-emission cars and long-lasting smartphones, batteries with low energy densities and dangerous fire hazards remain stubborn showstoppers. Commercial batteries have all but tapped out the maximum capabilities that lithium-based cells can deliver, and other alternatives are hampered by their individual deficiencies. Among emerging alternatives, zinc (Zn) systems, which rely on Zn anodes (positive terminal) and manganese oxide (MnO2) cathodes (negative terminal) coupled with Zn2+ organic salt electrolytes, offer a safe and energy-dense alternative. However, zinc electrochemistry leads to rapid growth of dendrites, which are needle-like metal deposits that accumulate on electrode surfaces during cycling and can easily short-circuit the batteries. While three-dimensional (3D) foams and solid electrolytes can alleviate this concern, existing configurations have not been sufficiently elastic, lightweight, or efficient to profoundly impact the energy-storage landscape.

Researchers from the University of Michigan–Ann Arbor, are exploring more effective and pliable zinc batteries with a solid electrolyte, and in this effort have looked to biomaterials for inspiration. They found that the structure of articular cartilage, which facilitates smooth bone-on-bone contact in joints, has a particularly strong collagen nanofiber network. The research team mimicked this network with a branched aramid (Kevlar) fibrous material and were able to develop a porous yet stiff 3D structure. This scaffold served as the backbone for a new solid electrolyte zinc battery with superior reliability, energy density, and high structural integrity. Most importantly, this biomimetic structure physically precludes the formation of dendrites. The research team collaborated with researchers from the Harbin Institute of Technology, China, and the Michigan Institute for Translational Nanotechnology, and published their results in a recent issue of ACS Nano (doi:10.1021/acsnano.8b05068).

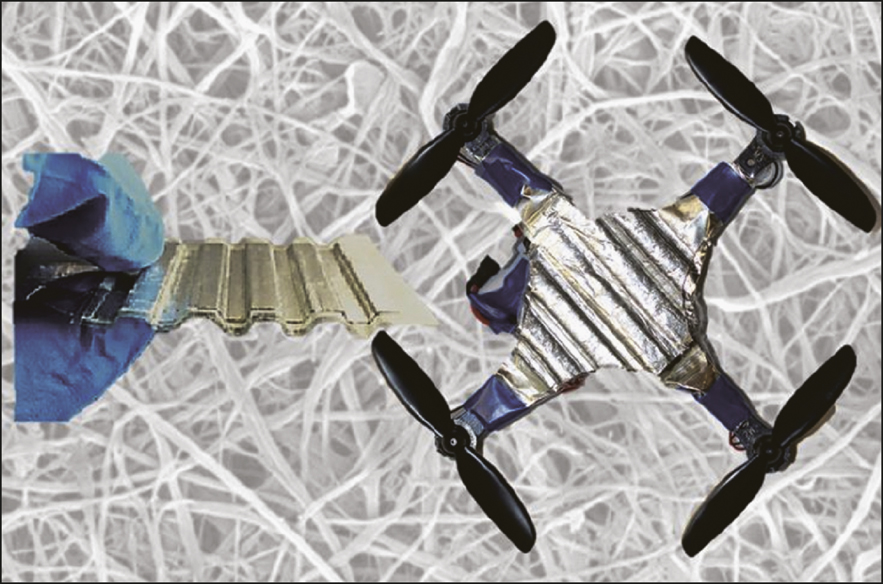

Corrugated zinc battery design relies on a 3D bioinspired aramid fiber network and facilitates its use in an unmanned aerial vehicle. Credit: Evan Dougherty and Ahmet Emre.

Nicholas Kotov describes the cornerstone of his team’s work. “Cartilage is an amazing material. It withstands large stresses and serves us for a very long time. We just learned how to replicate its structure from aramid nanofibers.”

The branched aramid fiber network accommodated a polyethylene oxide (PEO)//zinc trifluoromethanesulfonate (Zn(CF3SO3)2) solid electrolyte, which facilitates rapid ion transport between the Zn anode and MnO2 cathode. In fact, counterintuitively, the addition of the aramid fibers increased the conductivity of zinc ions tenfold. The complete device delivered 150 mAh/g at 1 C and operated in the 1–1.8 V potential range. After 100 cycles, it retained over 96% of its capacity—a sign of exceptional durability. The nanofiber/electrolyte composite offered a 58 MPa tensile strength and a 3.3 MPa Young’s modulus, which far exceeds any comparable cellulose or carbon nanotube-based alternatives.

High mechanical strength and uninterrupted performance during elastic and plastic deformation allowed corrugated (“teeth-shaped”) geometrical battery configurations. To put their fundamental design into the field, the researchers incorporated this battery design into the power source of a handheld aerial drone. Without adding any weight to the system, this seamless augmentation boosted flight time of the handheld aerial vehicle by 5–27%. Unmanned vehicles are always hungry for high-efficiency power sources, and the researchers, in a single stroke, showed how their fundamental materials discovery can advance into a real-life system.