Article contents

Understanding the brittleness of metallic glasses through dynamic clusters

Published online by Cambridge University Press: 13 February 2014

Abstract

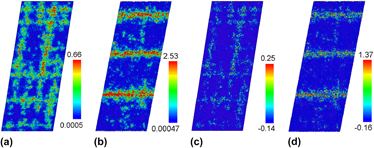

Exploiting molecular dynamics simulation, this article investigates the dynamic process of atomic rearrangement in two metallic glasses (MGs), Cu50Zr50 and Fe80P20, which are well known as ductile and brittle MGs under compression, respectively. It was found that the local rearrangements can be identified clearly by the distribution of kinetic energy and atomic strain rate, and that they are always driven by several high-velocity atoms in the core and induce a large shear and tensile strain over a very short duration. The size, kinetic energy, strain rate, and cavitation rate of the clusters in Fe80P20 are markedly larger than those in Cu50Zr50, which explains the distinct strength and brittleness of these two MGs. This study further confirmed that localized rearrangement of atomic structure is the underlying mechanism of plastic deformation in MGs, which governs their macro-scale mechanical performance.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2014

References

REFERENCES

- 2

- Cited by