Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Schwab, Thomas

Razouq, Hasan

Aicher, Korbinian

Zickler, Gregor A.

and

Diwald, Oliver

2020.

Apparent crystallite domain size growth in metal oxide nanocrystal ensembles: The importance of surface reactivity of powders for processing.

Open Ceramics,

Vol. 3,

Issue. ,

p.

100014.

Vlasov, V. P.

Muslimov, A. E.

and

Kanevsky, V. M.

2020.

Water Adsorption on the (001) Surface of NaCl.

Journal of Surface Investigation: X-ray, Synchrotron and Neutron Techniques,

Vol. 14,

Issue. 5,

p.

1040.

Gao, Qingwei

Zhang, Yumeng

Xu, Shuting

Laaksonen, Aatto

Zhu, Yudan

Ji, Xiaoyan

and

Lu, Xiaohua

2020.

Physicochemical properties and structure of fluid at nano-/micro-interface: Progress in simulation and experimental study.

Green Energy & Environment,

Vol. 5,

Issue. 3,

p.

274.

Niedermaier, Matthias

Schwab, Thomas

Kube, Pierre

Zickler, Gregor A.

Trunschke, Annette

and

Diwald, Oliver

2020.

Catalytic activity, water formation, and sintering: Methane activation over Co- and Fe-doped MgO nanocrystals.

The Journal of Chemical Physics,

Vol. 152,

Issue. 7,

Huo, Xiangchen

Conklin, Davis R.

Zhou, Mingxia

Vorotnikov, Vassili

Assary, Rajeev S.

Purdy, Stephen C.

Page, Katharine

Li, Zhenglong

Unocic, Kinga A.

Balderas, Raiven I.

Richards, Ryan M.

and

Vardon, Derek R.

2021.

Catalytic activity and water stability of the MgO(111) surface for 2-pentanone condensation.

Applied Catalysis B: Environmental,

Vol. 294,

Issue. ,

p.

120234.

Schwab, Thomas

Niedermaier, Matthias

Aicher, Korbinian

Elsässer, Michael S.

Zickler, Gregor A.

and

Diwald, Oliver

2021.

Always cubes: A comparative evaluation of gas phase synthesis methods and precursor selection for the production of MgO nanoparticles.

Open Ceramics,

Vol. 6,

Issue. ,

p.

100104.

Diwald, Oliver

2021.

Metal Oxide Nanoparticles.

p.

1.

Thomele, Daniel

Baumann, Stefan O.

Schneider, Johannes

Sternig, Andreas K.

Shulda, Sarah

Richards, Ryan M.

Schwab, Thomas

Zickler, Gregor A.

Bourret, Gilles R.

and

Diwald, Oliver

2021.

Cubes to Cubes: Organization of MgO Particles into One-Dimensional and Two-Dimensional Nanostructures.

Crystal Growth & Design,

Vol. 21,

Issue. 8,

p.

4674.

Diwald, Oliver

2021.

Metal Oxide Nanoparticles.

p.

783.

Schwab, Thomas

Aicher, Korbinian

Razouq, Hasan

Zickler, Gregor A.

and

Diwald, Oliver

2021.

Segregation Engineering in MgO Nanoparticle-Derived Ceramics: The Impact of Calcium and Barium Admixtures on the Microstructure and Light Emission Properties.

ACS Applied Materials & Interfaces,

Vol. 13,

Issue. 21,

p.

25493.

Diwald, Oliver

and

Hartmann, Martin

2021.

Metal Oxide Nanoparticles.

p.

593.

Schneider, Johannes

Ziegler, Amelie

Zickler, Gregor A.

Dzik, Petr

Berger, Thomas

and

Diwald, Oliver

2022.

TiO2 anatase and rutile grains and the effect of particle printing on porphyrin adsorption.

Surface Science,

Vol. 722,

Issue. ,

p.

122083.

Vasudevan, A.K.

Ricker, R.E.

Miller, A.C.

and

Kujawski, D.

2022.

Fatigue crack tip corrosion processes and oxide induced closure.

Materials Science and Engineering: A,

Vol. 861,

Issue. ,

p.

144383.

Schwab, Thomas

Muchová, Eva

Aicher, Korbinian

Berger, Thomas

Ončák, Milan

and

Diwald, Oliver

2023.

Oxygen Radicals Entrapped between MgO Nanocrystals: Formation, Spectroscopic Fingerprints, and Reactivity toward Water.

The Journal of Physical Chemistry C,

Vol. 127,

Issue. 48,

p.

23332.

Luong, N. Tan

and

Boily, Jean-François

2023.

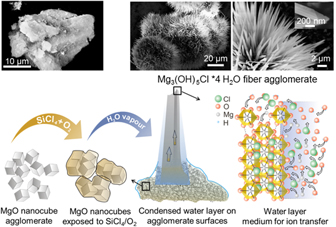

Water Film-Driven Brucite Nanosheet Growth and Stacking.

Langmuir,

Vol. 39,

Issue. 31,

p.

11090.

Luong, N. Tan

Holmboe, Michael

and

Boily, Jean-François

2023.

MgO nanocube hydroxylation by nanometric water films.

Nanoscale,

Vol. 15,

Issue. 24,

p.

10286.

Bulyarskiy, Sergey Viktorovich

L’vov, Pavel Evgenievich

Litvinova, Kristina Igorevna

Polomskikh, Vitaliy Sergeevich

and

Rudakov, Grigory Aleksandrovich

2024.

Water Dose influence to the ALD hafnium oxide process: Simulation and experiment.

Materials Today Communications,

Vol. 39,

Issue. ,

p.

108622.

Luong, N. Tan

Hanna, Khalil

and

Boily, Jean-François

2024.

Water film-mediated photocatalytic oxidation of oxalate on TiO2.

Journal of Catalysis,

Vol. 432,

Issue. ,

p.

115425.

King, Hubert

Murphy, Ryan

Baumann, Avery

Allen, Andrew

Nguyen, Huong Giang T.

DeBeer-Schmitt, Lisa

and

Ilavsky, Jan

2025.

Carbonation of Alkaline Earth Metal Hydroxides: Structure across Nano- to Mesoscales.

Energy & Fuels,

Vol. 39,

Issue. 10,

p.

4866.