Article contents

Thermal behavior and formation mechanism of a typical micro-scale node-structure during selective laser melting of Ti-based porous structure

Published online by Cambridge University Press: 18 April 2017

Abstract

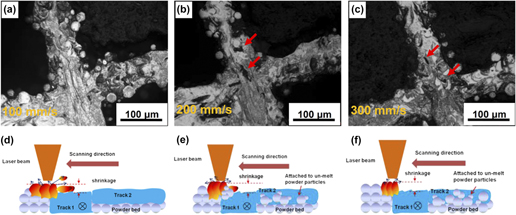

Selective laser melting (SLM) technology efficiently solves the current manufacturing challenges of high-performance porous structure components, due to its freeform fabrication principle. As the most basic and crucial structure element, the nodes of porous structure component play an important role in its mechanical property. In this study, finite element method was used to investigate the thermal behavior during SLM processing of micro-scale node-structure. The dynamic size of molten pool was continuously predicted and consequently the typical “necking” effect was found, which was consistent with the experiment results. Besides, the influence of laser scan speed on temperature and temperature gradient of molten pool was also analyzed. The results indicated that the “necking” effect became more conspicuous with the applied scan speed increasing, which significantly deteriorated the mechanical property of porous structure components.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 7

- Cited by