Published online by Cambridge University Press: 26 July 2011

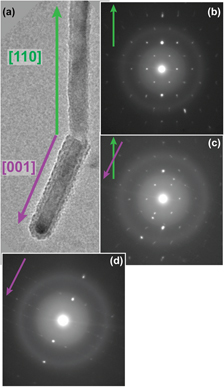

Syntaxial growth of Mn11Ge8/Ge nanowire heterostructures was carried out using a vapor–solid–solid (VSS) growth process, and transmission electron microscopy imaging and selected-area electron diffraction were used to study the structure, orientation, and interface of each phase. Preferred crystallographic relationships were found to exist between the Mn11Ge8 seeds, which exhibit a single uniaxial growth direction, and the seeded Ge nanowires, which exhibit multiple growth directions. The crystallographic relationships for individual nanowire heterostructures were characterized in the context of microtexture analysis, which has not previously been applied to nanowire heterostructures. Fiber and off-normal fiber textures were predominant, although examples of epitaxial and uniaxial in-plane textures were also identified. Microtexture analysis of VSS-grown nanowire systems is shown to provide a useful perspective on the products of synthesis that can lead to new insights into growth mechanisms.