Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Gulzar, M.

Masjuki, H. H.

Kalam, M. A.

Varman, M.

Zulkifli, N. W. M.

Mufti, R. A.

and

Zahid, Rehan

2016.

Tribological performance of nanoparticles as lubricating oil additives.

Journal of Nanoparticle Research,

Vol. 18,

Issue. 8,

Liñeira del Río, José M.

Guimarey, María J.G.

Comuñas, María J.P.

López, Enriqueta R.

Amigo, Alfredo

and

Fernández, Josefa

2018.

Thermophysical and tribological properties of dispersions based on graphene and a trimethylolpropane trioleate oil.

Journal of Molecular Liquids,

Vol. 268,

Issue. ,

p.

854.

Gulzar, Mubashir

2018.

Tribological Study of Nanoparticles Enriched Bio-based Lubricants for Piston Ring–Cylinder Interaction.

p.

7.

Zahid, Rehan

Mufti, Riaz Ahmad

Gulzar, Mubashir

Bin Haji Hassan, Masjuki

Alabdulkarem, Abdullah

Varman, Mahendra

Kalam, Md Abul

Binti Mohd Zulkifli, Nurin Wahidah

and

Yunus, Robiah

2018.

Tribological compatibility analysis of conventional lubricant additives with palm trimethylolpropane ester (TMP) and tetrahedral amorphous diamond-like carbon coating (ta-C).

Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology,

Vol. 232,

Issue. 8,

p.

999.

He, Chuang

Yan, Honghao

Wang, Xiaohong

and

Bai, Minli

2018.

Graphene quantum dots prepared by gaseous detonation toward excellent friction-reducing and antiwear additives.

Diamond and Related Materials,

Vol. 89,

Issue. ,

p.

293.

Zainal, N.A.

Zulkifli, N.W.M.

Gulzar, M.

and

Masjuki, H.H.

2018.

A review on the chemistry, production, and technological potential of bio-based lubricants.

Renewable and Sustainable Energy Reviews,

Vol. 82,

Issue. ,

p.

80.

Singh, Sudesh

Chen, Xinchun

Zhang, Chenhui

Tyagi, Rajnesh

and

Luo, Jianbin

2019.

Investigation on the lubrication potential of graphene oxide aqueous dispersion for self-mated stainless steel tribo-pair.

Vacuum,

Vol. 166,

Issue. ,

p.

307.

Alghani, Waleed

Ab Karim, Mohd S.

Bagheri, Samira

Amran, Nor Amirah M.

and

Gulzar, M.

2019.

Enhancing the Tribological Behavior of Lubricating Oil by Adding TiO2, Graphene, and TiO2/Graphene Nanoparticles.

Tribology Transactions,

Vol. 62,

Issue. 3,

p.

452.

Huang, Jigang

Tan, Jun

Fang, Hui

Gong, Feng

and

Wang, Jie

2019.

Tribological and wear performances of graphene-oil nanofluid under industrial high-speed rotation.

Tribology International,

Vol. 135,

Issue. ,

p.

112.

Guimarey, María J.G.

Comuñas, María J.P.

López, Enriqueta R.

Amigo, Alfredo

and

Fernández, Josefa

2019.

Thermophysical properties of polyalphaolefin oil modified with nanoadditives.

The Journal of Chemical Thermodynamics,

Vol. 131,

Issue. ,

p.

192.

Wang, Xinbo

Zhang, Yafei

Yin, Zhongwei

Su, Yanjie

Zhang, Yanping

and

Cao, Jun

2019.

Experimental research on tribological properties of liquid phase exfoliated graphene as an additive in SAE 10W-30 lubricating oil.

Tribology International,

Vol. 135,

Issue. ,

p.

29.

Bhaumik, Shubrajit

Pathak, S.D.

Dey, Swati

and

Datta, Shubhabrata

2019.

Artificial intelligence based design of multiple friction modifiers dispersed castor oil and evaluating its tribological properties.

Tribology International,

Vol. 140,

Issue. ,

p.

105813.

Pham, Sang T.

Wan, Shanhong

Tieu, Kiet A.

Ma, Ming

Zhu, Hongtao

Nguyen, Huynh H.

Mitchell, David R. G.

and

Nancarrow, Mitchell J.

2019.

Unusual Competitive and Synergistic Effects of Graphite Nanoplates in Engine Oil on the Tribofilm Formation.

Advanced Materials Interfaces,

Vol. 6,

Issue. 19,

Azman, Nurul Farhanah

and

Samion, Syahrullail

2019.

Dispersion Stability and Lubrication Mechanism of Nanolubricants: A Review.

International Journal of Precision Engineering and Manufacturing-Green Technology,

Vol. 6,

Issue. 2,

p.

393.

Paul, Gayatri

Hirani, Harish

Kuila, Tapas

and

Murmu, N. C.

2019.

Nanolubricants dispersed with graphene and its derivatives: an assessment and review of the tribological performance.

Nanoscale,

Vol. 11,

Issue. 8,

p.

3458.

Srivyas, Pranav Dev

and

Charoo, M. S.

2019.

Advances in Engineering Design.

p.

239.

de Paiva, Raphael Lima

de Souza Ruzzi, Rodrigo

de Oliveira, Letícia Raquel

Bandarra Filho, Enio Pedone

Gonçalves Neto, Luiz Mauricio

Gelamo, Rogério Valentim

and

da Silva, Rosemar Batista

2020.

Experimental study of the influence of graphene platelets on the performance of grinding of SAE 52100 steel.

The International Journal of Advanced Manufacturing Technology,

Vol. 110,

Issue. 1-2,

p.

1.

C., Pownraj

and

A., Valan Arasu

2020.

Preparation and characterization of low cost eco-friendly GAO grafted bio‑carbon nanoparticle additive for enhancing the lubricant performance.

Diamond and Related Materials,

Vol. 108,

Issue. ,

p.

107921.

Owuna, F.J.

2020.

Stability of vegetable based oils used in the formulation of ecofriendly lubricants – a review.

Egyptian Journal of Petroleum,

Vol. 29,

Issue. 3,

p.

251.

La, Duong Duc

Truong, Tuan Ngoc

Pham, Thuan Q.

Vo, Hoang Tung

Tran, Nam The

Nguyen, Tuan Anh

Nadda, Ashok Kumar

Nguyen, Thanh Tung

Chang, S. Woong

Chung, W. Jin

and

Nguyen, D. Duc

2020.

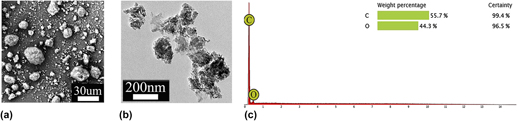

Scalable Fabrication of Modified Graphene Nanoplatelets as an Effective Additive for Engine Lubricant Oil.

Nanomaterials,

Vol. 10,

Issue. 5,

p.

877.