Article contents

The study of preparation process of spray formed 7075/Al–Si bimetallic gradient composite plate

Published online by Cambridge University Press: 02 May 2017

Abstract

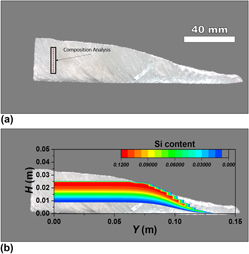

To determine the spray forming process parameters of 7075/Al–Si bimetallic gradient composite plate with two gas atomizers, a calculation model of the plate has been established by using the finite element software ANSYS. The effects of different motion trajectory, advance speed, swing cycle and spray center distance on shape, and silicon distribution of deposited plate have been simulated by the APDL programming language. The results show that a smooth and uniform surface is obtained when motion trajectory is in a regular jaggies mode. The deposited plate varies from platform to stepped shape with a center distance increasing from 20 mm to 50 mm; meanwhile, the width of the transition zone decreases gradually. As the period increases to 8 s, the silicon distribution of each layer presents a jagged fluctuation. Both the thickness of the deposited plate and the width of the transition zone decrease as the advance speed increases, except the silicon distribution. Finally, the modeling and simulation of the co-spray formed 7075/Al–Si bimetallic gradient composite plate are validated by experimental investigations and the simulation results are in good agreement with the actual results.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 6

- Cited by