No CrossRef data available.

Article contents

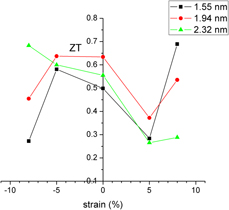

Strain dependence of the thermoelectric performance of porous armchair silicene nanoribbons

Published online by Cambridge University Press: 11 November 2019

Abstract

In this article, the strain-dependent thermoelectric performance of circular porous armchair silicene nanoribbons (ASiNRs) under uniaxial tension and compression is computed by means of a semiempirical approach in combination with nonequilibrium Green’s function. Our findings clearly demonstrate that the thermoelectric performance can be effectively tuned by the optimum choice of the nature and magnitude of the strain depending on the pore size. For smaller pore sizes, higher tensile strains can be preferred whereas for nanostructures with larger pores, the compression is a suitable option. Further analysis concludes that the tensile deformation fails to attain any improvement in the thermoelectric figure of merit ZT at any choice of temperature, whereas the performance under compressive deformation goes on improving with the increase in the applied temperature. In addition, changing the pore shape to a triangular one is found to significantly enhance the thermoelectric performance.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019