Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Zheng, He

Wu, Shujing

Sheng, Huaping

Liu, Chun

Liu, Yu

Cao, Fan

Zhou, Zhichao

Zhao, Xingzhong

Zhao, Dongshan

and

Wang, Jianbo

2014.

Direct atomic-scale observation of layer-by-layer oxide growth during magnesium oxidation.

Applied Physics Letters,

Vol. 104,

Issue. 14,

Cao, Fan

Zheng, He

Jia, Shuangfeng

Liu, Huihui

Li, Lei

Chen, Boyun

Liu, Xi

Wu, Shujing

Sheng, Huaping

Xing, Ru

Zhao, Dongshan

and

Wang, Jianbo

2016.

Atomistic Observation of Structural Evolution during Magnesium Oxide Growth.

The Journal of Physical Chemistry C,

Vol. 120,

Issue. 47,

p.

26873.

Liu, Huihui

Zheng, He

Li, Lei

Sheng, Huaping

Jia, Shuangfeng

Cao, Fan

Liu, Xi

Chen, Boyun

Xing, Ru

Zhao, Dongshan

and

Wang, Jianbo

2017.

Atomic-scale observation of a two-stage oxidation process in Cu2O.

Nano Research,

Vol. 10,

Issue. 7,

p.

2344.

Xiang, Lijun

Guo, Jian

Wu, Chenhui

Cai, Menglei

Zhou, Xinrong

and

Zhang, Nailiang

2018.

A brief review on the growth mechanism of CuO nanowires via thermal oxidation.

Journal of Materials Research,

Vol. 33,

Issue. 16,

p.

2264.

Jia, Shuangfeng

Li, Lei

Zhao, Lulu

Zheng, He

Zhao, Peili

Guan, Xiaoxi

Chen, Guoxujia

Wu, Jiangbing

Zhou, Siyuan

and

Wang, Jianbo

2018.

Surface-dependent formation of Zn clusters in ZnO single crystals by electron irradiation.

Physical Review Materials,

Vol. 2,

Issue. 6,

Ao, Yibo

Ao, Jinqing

Yang, Xiaoshan

Zhao, Ling

Hu, Liwei

Le, Guomin

Li, Jinfeng

Qu, Fengsheng

Zhou, Yuzhao

Wang, Xiaoying

Guo, Biao

and

Liu, Xue

2020.

Preparation and characterization of hierarchical nanostructures composed by CuO nanowires within directional microporous Cu.

Vacuum,

Vol. 182,

Issue. ,

p.

109774.

Jin, Lei

Zapf, Michael

Stübinger, Martin

Kamp, Martin

Sing, Michael

Claessen, Ralph

and

Jia, Chun-Lin

2020.

Atomic‐Scale Interface Structure in Domain Matching Epitaxial BaBiO3 Thin Films Grown on SrTiO3 Substrates.

physica status solidi (RRL) – Rapid Research Letters,

Vol. 14,

Issue. 6,

Shi, Juan

Qiao, Liang

Zhao, Yi

Sun, Zhonggui

Feng, Wangjun

Zhang, Zhiya

Wang, Jun

and

Men, Xuehu

2020.

Synergistic effects on thermal growth of CuO nanowires.

Journal of Alloys and Compounds,

Vol. 815,

Issue. ,

p.

152355.

Hu, Liwei

Liu, Xue

Liang, Chuanhui

Zhao, Shaofan

Chen, Tianxiong

Li, Jinfeng

Le, Guomin

Qu, Fengsheng

Zhou, Yuzhao

Qi, Li

and

Wang, Dou

2021.

Microstructure evolution and corrosion mechanism of laser cladded Zr-Cu-Ni-Al in-situ metallic glass matrix composite coatings.

Surface and Coatings Technology,

Vol. 409,

Issue. ,

p.

126908.

Weber, Moritz L.

Wilhelm, Marek

Jin, Lei

Breuer, Uwe

Dittmann, Regina

Waser, Rainer

Guillon, Olivier

Lenser, Christian

and

Gunkel, Felix

2021.

Exsolution of Embedded Nanoparticles in Defect Engineered Perovskite Layers.

ACS Nano,

Vol. 15,

Issue. 3,

p.

4546.

Chao, Zhang

and

Dejun, Kong

2022.

Salt spray corrosion behavior and electrochemical performance of Al and Ti reinforced Ni60 coating by laser cladding.

Materials and Corrosion,

Vol. 73,

Issue. 7,

p.

1045.

Liu, Tao

Lyu, Weimin

Li, Zhicheng

Wang, Shengke

Wang, Xing

Jiang, Jiaxin

and

Jiang, Xiaosong

2023.

Recent progress on corrosion mechanisms of graphene-reinforced metal matrix composites.

Nanotechnology Reviews,

Vol. 12,

Issue. 1,

Wu, Xuelian

Wang, Yaping

Xia, Xinxin

Ding, Jianxiang

Zhang, Yundeng

Li, Gege

Ma, Chengjian

Pan, Long

Wang, Jinlong

and

Liu, Dongming

2025.

Understanding Cd Nano-Whisker Growth on Ti2CdC MAX Phase from the Perspective of Atomized Cd Migration.

JOM,

Vol. 77,

Issue. 2,

p.

822.

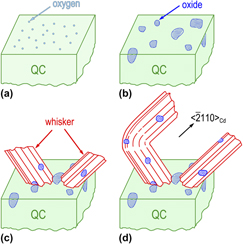

. CdO particles are frequently observed on surfaces of whiskers and the alloy, indicating the importance of the oxidation process during the whisker growth; (ii) there exist four types of orientation relationship between Cd and CdO. The interfaces between them are shown to accommodate large lattice misfit, which is well explained by near coincidence site lattice model; (iii) nanosized Cd particles are observed to aggregate around the whisker root, providing a convincing experimental evidence for the long-range atomic diffusion. Our study offers a unique opportunity to unveil the relationship between unstability of quasicrystal structure and whisker formation and may have some implications for oxidation process of metals.

. CdO particles are frequently observed on surfaces of whiskers and the alloy, indicating the importance of the oxidation process during the whisker growth; (ii) there exist four types of orientation relationship between Cd and CdO. The interfaces between them are shown to accommodate large lattice misfit, which is well explained by near coincidence site lattice model; (iii) nanosized Cd particles are observed to aggregate around the whisker root, providing a convincing experimental evidence for the long-range atomic diffusion. Our study offers a unique opportunity to unveil the relationship between unstability of quasicrystal structure and whisker formation and may have some implications for oxidation process of metals.