Article contents

Sequential self-assembly of micron-scale components with light

Published online by Cambridge University Press: 17 January 2011

Abstract

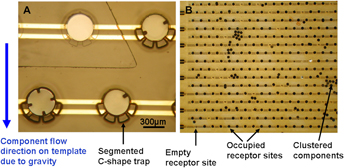

We present a versatile and flexible method to sequentially self-assemble micron-scale components at specific locations onto unconventional substrates, such as glass and plastic. In this method, components are independently batch fabricated and assembled onto a series of receptor sites incorporated onto a substrate in a fluid medium. Initially, all self-assembly sites are blocked with a photoresist polymer. Controlled light exposure can be used to remove the polymer and make a site available for receiving a microcomponent. By repeating this procedure, various microcomponents may be integrated onto specific locations on the substrate. To demonstrate the process, we prepared four types of 20 μm thick, 320 μm diameter circular silicon components and showed their optically controllable self-assembly in arrays of 640 receptor sites on glass and plastic with yields reaching 85%. The integration and operation of two types of functional components, red light-emitting diodes and silicon resistors, on plastic substrates was also demonstrated.

- Type

- Reviews

- Information

- Journal of Materials Research , Volume 26 , Issue 2: Focus Issue: Self-Assembly and Directed Assembly of Advanced Materials , 28 January 2011 , pp. 268 - 276

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 4

- Cited by