Published online by Cambridge University Press: 19 June 2017

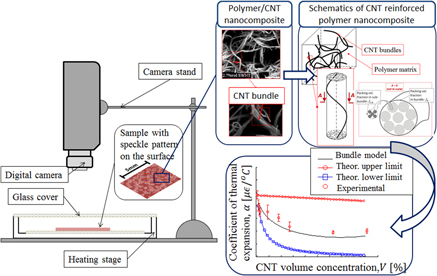

The thermal expansion behavior of polymer carbon nanotube (CNT) nanocomposites was investigated, and a micromechanical model was proposed to explain the highly nonlinear dependence of the coefficient of thermal expansion of the nanocomposite with CNT content for the CNT/polyimide nanocomposite. The microscopic analysis of CNT/polyimide matrix showed homogeneous dispersion of bundles composed of CNTs. Therefore, the proposed model to predict the thermal expansion behavior of the nanocomposite considered a random, homogeneous distribution of CNT bundles with a hierarchical arrangement of helical CNTs within the polymeric matrix. The CNT bundle morphology influenced the thermal expansion response of the nanocomposite through (i) bundle volume fraction and (ii) degree of helicity, affecting thermo-mechanical properties of the bundle. The effective, homogenized, properties of CNT bundles were determined by the elasticity based solution of the layered cylinder model. Bundle effective properties were used in the micromechanical model implementing the homogenized strain rule of the mixture expression to predict the thermal expansion behavior of nanocomposite in a wide range of CNT volume contents. The proposed micromechanical analytical model was found to correlate closely with the experimental results for polyimide/CNT nanocomposite films as measured using a digital image correlation method.

Contributing Editor: Linda S. Schadler

To send this article to your Kindle, first ensure no-reply@cambridge.org is added to your Approved Personal Document E-mail List under your Personal Document Settings on the Manage Your Content and Devices page of your Amazon account. Then enter the ‘name’ part of your Kindle email address below. Find out more about sending to your Kindle. Find out more about saving to your Kindle.

Note you can select to save to either the @free.kindle.com or @kindle.com variations. ‘@free.kindle.com’ emails are free but can only be saved to your device when it is connected to wi-fi. ‘@kindle.com’ emails can be delivered even when you are not connected to wi-fi, but note that service fees apply.

Find out more about the Kindle Personal Document Service.

To save this article to your Dropbox account, please select one or more formats and confirm that you agree to abide by our usage policies. If this is the first time you used this feature, you will be asked to authorise Cambridge Core to connect with your Dropbox account. Find out more about saving content to Dropbox.

To save this article to your Google Drive account, please select one or more formats and confirm that you agree to abide by our usage policies. If this is the first time you used this feature, you will be asked to authorise Cambridge Core to connect with your Google Drive account. Find out more about saving content to Google Drive.