Article contents

Reversible formation of stacking faults in a nickel-based single crystal TMS-82 superalloy

Published online by Cambridge University Press: 16 December 2013

Abstract

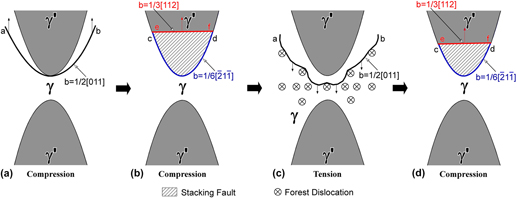

Thermomechanical fatigue (TMF) tests have been carried out in a nickel-based single crystal TMS-82 superalloy, and the dynamic evolutions of dislocations and stacking faults have been studied in detail. It is found that the reversible formation of stacking faults is always associated with the loading orientation. Specifically, stacking faults expand under compression and shrink under tension due to the disappearance and appearance of dislocations during the TMF process. Stacking faults result from shear of γ′ precipitates by 1/3<112> dislocations, which arise from the decomposition of 1/2<110> matrix dislocations. The calculations of critically resolved shear stress to push dislocations that glide in the γ′ particles confirm the expansion of stacking faults under compression. However, under tension, dislocations in γ channel prevent 1/2<110> dislocations to enter γ′ cuboids and consequently, stacking faults shrink. Appearance and disappearance of dislocations during TMF cycling are associated with plastic deformation and annealing process, respectively.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2013

References

REFERENCES

- 4

- Cited by