Article contents

Residual stress–driven test technique for freestanding ultrathin films: Elastic behavior and residual strain

Published online by Cambridge University Press: 14 October 2019

Abstract

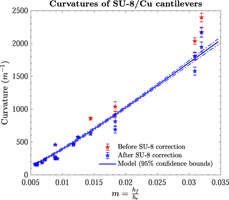

Elastic modulus and residual stress in freestanding ultrathin films (<100 nm) are characterized using bilayer cantilevers. The cantilevers comprise a test film and a well-characterized reference material (SU-8). When released from the substrate, residual stresses in the bilayer cantilever cause it to deflect with measurable curvatures, allowing the determination of both stiffness and residual stress of the test film. The technique does not require sophisticated mechanical test equipment and serves as a useful metrology tool for characterizing coatings immediately after fabrication in a clean room assembly line. The measured biaxial modulus and residual strain of 75 nm copper films are 211 ± 19 GPa and (7.05 ± 0.22) × 10−3, respectively. Additional experiments on the freestanding structures yield a mean Young’s modulus of 115 GPa. These properties are in close agreement with those measured from additional residual stress–driven structures developed on the same coatings by the authors.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

Footnotes

Present Address: KAIST, Daejeon, South Korea.

References

- 8

- Cited by