Article contents

Research on the coarsening mechanism of precipitations and its effect on toughness for nickel-based weld metal during thermal aging

Published online by Cambridge University Press: 04 March 2019

Abstract

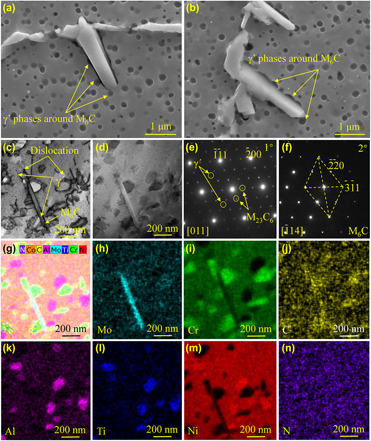

Coarsening mechanism of precipitations was investigated in a weld metal of Alloy 617 during long-term aging at 750 °C, and its effect on impact toughness was clarified distinctly. The needle-like M6C phases at the grain boundary nucleated and coarsened at 2000 h and then presented a stable size with aging to 8000 h. Spherical γ′ phase grew rapidly with the rate of 0.0121 nm/h when aged at 1000 h; then, its ripening rate (RR) reduced to 0.0033 nm/h at 8000 h and stabilized around it. The coarsening of M6C and γ′ was, respectively, controlled by interface diffusion and volume diffusion with the coarsening rate constant of 7.865 × 10−20 m2/s and 1.519 × 10−27 m3/s. Interaction of M6C and γ′ could facilitate their coarsening and cause dramatic decrease in toughness at the early stage. At aging to 8000 h and more, the lower RR of needle-like M6C phases and γ′ phases helped to form stable toughness at a later stage.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2019

References

- 2

- Cited by