Article contents

The quench sensitivity of SiCp/2024Al composites based on Jominy end quench test

Published online by Cambridge University Press: 06 April 2016

Abstract

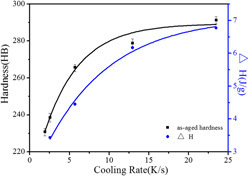

The quench sensitivity of 45vol% SiCp/2024Al composites manufactured by squeezed casting method has been investigated by employing Jominy end quench test which was designed to simulate the one dimension cooling process of the composites. It can be found that the cooling rates decreased with the increase of the distance from the quenched end. The results indicated that the as-quenched and as-aged hardness exhibited a significant decrease with increasing the distance from the quenched end. The depths corresponding to 90% of maximum as-aged hardness were 30 mm. When the quench cooling rate was 23.5 °C/s, the hardness was the maximum. The variation of as-aged hardness with cooling rate was identical with the overall enthalpy involved in the precipitation of all metastable phases (S″ + θ″ + S′ + θ′). The SiCp/2024Al composites exhibited two sensitivity regimes: at slower cooling rates the quench sensitivity had been attributed to the formation of intermediate precipitates during cooling, while it was mildly quench sensitive at higher cooling rates.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 1

- Cited by