Article contents

Prediction of residual stress components and their directions from pile-up morphology: An experimental study

Published online by Cambridge University Press: 26 July 2016

Abstract

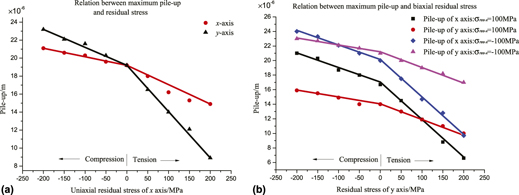

Indentation method has been widely used in the measurement of material mechanical properties and residual stress for its simple, fast and nondestructive characteristics. In the indentation test, because of the plastic deformation of the material, the material accumulation and subsidence occurs around the indentation. It is found that the deformation amount of the indentation, especially the maximum pile-up around the indentation after unloading, is related to the magnitude and direction of the residual stress. In this paper, an experimental study on the pile-up morphology around an indentation for determining the direction and magnitude of residual stress is reported. Nonsymmetrical morphology of spherical indenting deformation on artificially strained steel specimen was measured with a laser scanning confocal system. A unique relationship between pile-up after unloading and biaxial residual stress was set up based on the experimental results. The direction and components of nonequibiaxial residual stress can be determined by the proposed method.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 4

- Cited by