Article contents

Polyetherimide powders as material alternatives for selective laser-sintering components for aerospace applications

Published online by Cambridge University Press: 16 November 2020

Abstract

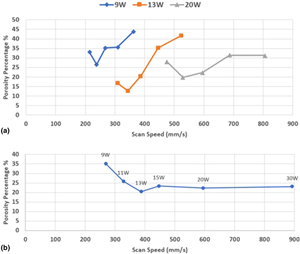

Additive manufacturing (AM) has made long strides in the recent past and rapidly evolved into a promising alternative in specific applications. The aircraft industry is not an exception to this. The true just-intime production possibility is critical for the aircraft maintenance industries, though the lack of material freedom is a major hurdle. Several fire-retardant materials were investigated for AM in the aerospace context, but mainly for fused deposition modeling (FDM). The material consolidation constraints in FDM led to the expansion to the use of selective laser sintering (SLS) to some extent. Nevertheless, the material options are still limited, proprietary, and lack scientific insights into the material consolidation mechanics. Attempts are made in this paper to fill this gap, evaluating a new fire-retardant material for processing by SLS. Experiments conducted to ascertain the material, process, structure, and consolidation relationships indicated energy density levels 0.062–0.070 J/mm2 with laser power 13 W and scan speed varied slightly around 390 mm/s to give the best laser sintering and mechanical property results in polyetherimide powders.

Keywords

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 10

- Cited by