Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Bahçe, Erkan

Demirel, Maruf H.

Köytepe, Süleyman

and

Seçkin, Turgay

2020.

Production of abrasive apricot kernel shell powder/boron nitride/polyester composites for cleaning of paint and corrosion on metal surfaces.

Polymer Composites,

Vol. 41,

Issue. 2,

p.

544.

Pan, Jisheng

Chen, Zhijun

and

Yan, Qiusheng

2020.

Study on the rheological properties and polishing properties of SiO2@CI composite particle for sapphire wafer.

Smart Materials and Structures,

Vol. 29,

Issue. 11,

p.

114003.

Nadimi Bavil Oliaei, Samad

Mukhtarkhanov, Muslim

and

Perveen, Asma

2020.

Advances in Abrasive Based Machining and Finishing Processes.

p.

235.

Liu, Lu

Zhang, Zhenyu

Wu, Bin

Hu, Wei

Meng, Fanning

and

Li, Yubiao

2021.

A review: green chemical mechanical polishing for metals and brittle wafers.

Journal of Physics D: Applied Physics,

Vol. 54,

Issue. 37,

p.

373001.

Liu, Zhixiang

and

Tang, Yunqing

2021.

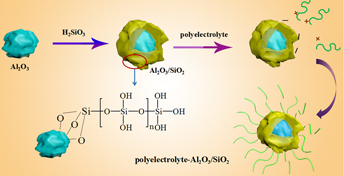

An approach for hydrophobic fixed abrasive pad based on layer-by-layer method.

Microelectronic Engineering,

Vol. 238,

Issue. ,

p.

111505.

Yu, Haiyang

Tang, Xiaoxue

Kong, Xue

Li, Xing’ai

Li, Yanpei

Xi, Mengfei

Chang, Tongtong

Meng, Danni

Yang, Senlin

Guo, Wanying

Zhang, Yanfeng

Zhang, Zefang

and

Rao, Pinhua

2021.

Electrostatic Self-Assembled Composite Abrasives for Chemical Mechanical Polishing of A-Plane Sapphire.

ECS Journal of Solid State Science and Technology,

Vol. 10,

Issue. 11,

p.

114002.

Zhang, Zhenyu

Liu, Jie

Hu, Wei

Zhang, Lezhen

Xie, Wenxiang

and

Liao, Longxing

2021.

Chemical mechanical polishing for sapphire wafers using a developed slurry.

Journal of Manufacturing Processes,

Vol. 62,

Issue. ,

p.

762.

Zhou, Chen

Xu, Xiangyang

Dai, Lei

Gong, Haiming

and

Lin, Shuntian

2021.

Chemical-mechanical polishing performance of core-shell structured polystyrene@ceria/nanodiamond ternary abrasives on sapphire wafer.

Ceramics International,

Vol. 47,

Issue. 22,

p.

31691.

Ogugua, Simon N.

Ntwaeaborwa, Odireleng M.

and

Swart, Hendrik C.

2021.

Luminescence, structure and insight on the inversion degree from normal to inverse spinel in a ZnAl(2−)Fe3+O4 system.

Boletín de la Sociedad Española de Cerámica y Vidrio,

Vol. 60,

Issue. 3,

p.

147.

Zhou, Mufang

Zhong, Min

and

Xu, Wenhu

2022.

Effects of ultrasonic amplitude on sapphire ultrasonic vibration assisted chemical mechanical polishing by experimental and CFD method.

Mechanics of Advanced Materials and Structures,

Vol. 29,

Issue. 28,

p.

7086.

Xu, Yongchao

Lin, Chen

Wang, Qianting

Zheng, Charlesming

Zhan, Youji

and

Chen, Bingsan

2022.

A novel polishing process with rigid-flexible composite structure plate for sapphire wafer polishing.

The International Journal of Advanced Manufacturing Technology,

Vol. 122,

Issue. 2,

p.

659.

Do, Tan-Tai

and

Fang, Te-Hua

2023.

Deep insights into interaction behaviour and material removal of β-SiC wafer in nanoscale polishing.

Tribology International,

Vol. 186,

Issue. ,

p.

108639.

Zhou, Mufang

Zhong, Min

and

Xu, Wenhu

2023.

Novel model of material removal rate on ultrasonic-assisted chemical mechanical polishing for sapphire.

Friction,

Vol. 11,

Issue. 11,

p.

2073.

Li, Shaoping

Fu, Jieni

He, Zhaobo

Luo, Yue

and

Wu, Shuilin

2023.

Nanomaterials and Equipment for Chemical–Mechanical Polishing of Single-Crystal Sapphire Wafers.

Coatings,

Vol. 13,

Issue. 12,

p.

2081.

Zhou, Mufang

Cheng, Yuanyao

Zhong, Min

and

Xu, Wenhu

2023.

Macro and micro-nano machining mechanism for ultrasonic vibration assisted chemical mechanical polishing of sapphire.

Applied Surface Science,

Vol. 640,

Issue. ,

p.

158343.

Zhou, Mufang

Zhong, Min

Xu, Wenhu

Li, Xiaobing

Yi, Meirong

and

Chen, Jianfeng

2024.

Effects of Frequency on the Performance of Ultrasonic Vibration Assisted Chemical Mechanical Polishing for Sapphire.

ECS Journal of Solid State Science and Technology,

Vol. 13,

Issue. 10,

p.

104007.

Xu, Yongchao

Peng, Cheng

Zhan, Youji

and

Wang, Qianting

2024.

Machining performance and material removal mechanism of sapphire with novel polishing slurry.

Applied Surface Science,

Vol. 671,

Issue. ,

p.

160756.

Xu, Hanqi

Luo, Ruiwen

Li, Zhengling

Yan, Zipeng

Zhao, Yujun

and

Su, Hongjiu

2024.

Influence of alumina precursors on the microstructural and physicochemical characteristics of alumina-coated silica nanocomposite particles.

Materials Today Chemistry,

Vol. 38,

Issue. ,

p.

102066.

Luo, Ziyuan

Lu, Jiabin

Yan, Qiusheng

Hu, Da

and

Zhou, Yongze

2024.

Influence of SiO2–ZnO mixed soft abrasive on tribological behavior and polishing performance of sapphire wafer.

Materials Science in Semiconductor Processing,

Vol. 176,

Issue. ,

p.

108318.

Chen, Xiangyan

Zhang, Zhenyu

Zhao, Feng

Luo, Hao

Wang, Jianmei

Meng, Fanning

Zhou, Hongxiu

Zhuang, Xuye

and

Li, Guo

2025.

Review on chemical mechanical polishing for atomic surfaces using advanced rare earth abrasives.

Journal of Physics D: Applied Physics,

Vol. 58,

Issue. 2,

p.

023004.