Article contents

Nanotribological properties of few layer graphene surfaces, prepared by bottom-up and top-down methods, in ambient air and liquid environments

Published online by Cambridge University Press: 15 March 2016

Abstract

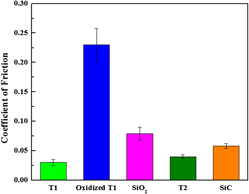

The role of bottom-up and top-down synthesis methods on the nanotribological response of few layer graphene (FLG) in air and various liquid environments is reported. Oxidized FLG adhesion against Si increases by a factor of 2 as compared to non-oxidized samples. Also, it is reported that the FLG center-to-edge adhesion typically exhibits a decreasing tendency. In air, a highly lubricious nanotribological response (0.03–0.04) of both bottom-up and top-down prepared samples is measured. The frictional behavior of bottom-up synthesized FLG in different liquid environments is found to depend on the absence or presence of viscous aggregates in the respective liquid. A Stribeck-like behavior is suggested for viscous synthetic lubricants, such as silicone, present as the third body in the FLG/Si tip system. Such nanoscale behavior, indicating transitions in different lubrication regimes, may be particularly important for the further understanding of liquid–graphene interfaces in novel tribological and device applications.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 31 , Issue 13: Focus Issue: Advances and Challenges in Carbon-based Tribomaterials , 14 July 2016 , pp. 1924 - 1931

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 1

- Cited by