Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Long, Fei

Yasaei, Poya

Yao, Wentao

Salehi-Khojin, Amin

and

Shahbazian-Yassar, Reza

2017.

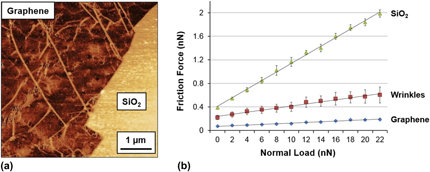

Anisotropic Friction of Wrinkled Graphene Grown by Chemical Vapor Deposition.

ACS Applied Materials & Interfaces,

Vol. 9,

Issue. 24,

p.

20922.

Tripathi, Manoj

Awaja, Firas

Bizao, Rafael A.

Signetti, Stefano

Iacob, Erica

Paolicelli, Guido

Valeri, Sergio

Dalton, Alan

and

Pugno, Nicola Maria

2018.

Friction and Adhesion of Different Structural Defects of Graphene.

ACS Applied Materials & Interfaces,

Vol. 10,

Issue. 51,

p.

44614.

Afsharimani, Nasima

Uluutku, Berkin

Saygin, Verda

and

Baykara, Mehmet Z.

2018.

Self-Assembled Molecular Films of Alkanethiols on Graphene for Heavy Metal Sensing.

The Journal of Physical Chemistry C,

Vol. 122,

Issue. 1,

p.

474.

Pershin, Vladimir

Ovchinnikov, Kirill

Al-Hilo, Zaman

Memetov, Nariman

Tkachev, Alexey

and

Galunin, Evgeny

2018.

A graphene masterbatch for modification of frost-resistant plastic lubricants.

Vol. 2035,

Issue. ,

p.

020016.

Shen, Bin

Huang, Zhewei

Ji, Zhe

Lin, Qiang

Chen, Sulin

Cui, Danjie

and

Zhang, Zhinan

2019.

Bilayer graphene film synthesized by hot filament chemical vapor deposition as a nanoscale solid lubricant.

Surface and Coatings Technology,

Vol. 380,

Issue. ,

p.

125061.

Dagdeviren, Omur E.

Acikgoz, Ogulcan

Grütter, Peter

and

Baykara, Mehmet Z.

2020.

Direct imaging, three-dimensional interaction spectroscopy, and friction anisotropy of atomic-scale ripples on MoS2.

npj 2D Materials and Applications,

Vol. 4,

Issue. 1,

Acikgoz, Ogulcan

and

Baykara, Mehmet Z.

2020.

Speed dependence of friction on single-layer and bulk MoS2 measured by atomic force microscopy.

Applied Physics Letters,

Vol. 116,

Issue. 7,

Feng, Xin

Li, Lingling

and

Wei, Zhiyong

2020.

The effect of substrate on the tribological properties of graphene.

p.

377.

Huang, Zhewei

Lin, Qiang

Ji, Zhe

Chen, Sulin

and

Shen, Bin

2020.

The Interior Failure of Single‐Layer Graphene Activated by the Nanosized Asperity on the Substrate Surface.

Advanced Materials Interfaces,

Vol. 7,

Issue. 12,

Hussain, Sabir

Xu, Rui

Xu, Kunqi

Lei, Le

Meng, Lan

Zheng, Zhiyue

Xing, Shuya

Guo, Jianfeng

Dong, Haoyu

Liaqat, Adeel

Iqbal, Muhammad Ahsan

Li, Yan Jun

Sugawara, Yasuhiro

Pang, Fei

Ji, Wei

Xie, Liming

and

Cheng, Zhihai

2020.

Strain-induced hierarchical ripples in MoS2 layers investigated by atomic force microscopy.

Applied Physics Letters,

Vol. 117,

Issue. 15,

Shen, Bin

Chen, Sulin

Huang, Zhewei

Ji, Zhe

Lin, Qiang

and

Zhang, Zhinan

2020.

Elucidating the atomic mechanism of the lubricity of graphene on the diamond substrate.

Applied Surface Science,

Vol. 504,

Issue. ,

p.

144372.

Chen, Sulin

Shen, Bin

Huang, Zhewei

Ji, Zhe

Lin, Qiang

and

Zhang, Zhinan

2021.

Controlled friction on graphene via substrate deformation induced atomic pinning effect.

Computational Materials Science,

Vol. 190,

Issue. ,

p.

110315.

Zhang, Zhinan

Yin, Nian

Chen, Shi

and

Liu, Chengliang

2021.

Tribo-informatics: Concept, architecture, and case study.

Friction,

Vol. 9,

Issue. 3,

p.

642.

Keskin, Yasemin

Ünverdi, Özhan

Erbahar, Dogan

Kaya, İsmet İnönü

and

Çelebi, Cem

2021.

The role of charge distribution on the friction coefficients of epitaxial graphene grown on the Si-terminated and C-terminated faces of SiC.

Carbon,

Vol. 178,

Issue. ,

p.

125.

Huang, Zhewei

Chen, Sulin

Lin, Qiang

Ji, Zhe

Gong, Peng

Sun, Zhengzong

and

Shen, Bin

2021.

Microscopic Mechanisms Behind the High Friction and Failure Initiation of Graphene Wrinkles.

Langmuir,

Vol. 37,

Issue. 22,

p.

6776.

Huang, Zhewei

Chen, Sulin

Lin, Qiang

Ji, Zhe

Gong, Peng

Sun, Zhengzong

and

Shen, Bin

2022.

The mechanisms of friction enhancements on graphene surfaces with folds: The reinforcement of atomic pinning or attraction.

Tribology International,

Vol. 165,

Issue. ,

p.

107297.

Antonov, P. V.

Restuccia, P.

Righi, M. C.

and

Frenken, J. W. M.

2022.

Attractive curves: the role of deformations in adhesion and friction on graphene.

Nanoscale Advances,

Vol. 4,

Issue. 19,

p.

4175.

Gi Choi, Min

Park, Seonha

Lee, Habeom

and

Kim, Songkil

2022.

Correlating surface structures and nanoscale friction of CVD Multi-Layered graphene.

Applied Surface Science,

Vol. 584,

Issue. ,

p.

152572.

Adabasi, Gokay

Deshpande, Aditya

Tanaka, Koichi

Ancheta, Joshua

Maldonado, Emmanuel

Özdoğan, Mehmet

Kodambaka, Suneel

and

Baykara, Mehmet Z.

2023.

Nanoscale friction of high entropy alloy sulfide thin films in comparison with molybdenum disulfide.

Applied Physics Letters,

Vol. 123,

Issue. 26,

Mohammed, Anwaruddin Siddiqui

Dodla, Srihari

Katiyar, Jitendra Kumar

and

Samad, Mohammed Abdul

2023.

Prediction of friction coefficient of su-8 and its composite coatings using machine learning techniques.

Proceedings of the Institution of Mechanical Engineers, Part J: Journal of Engineering Tribology,

Vol. 237,

Issue. 4,

p.

943.