Published online by Cambridge University Press: 16 September 2019

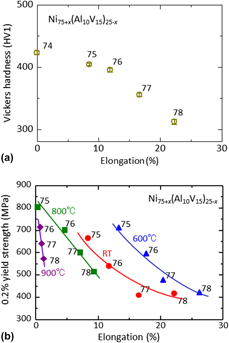

The effect of off-stoichiometry on the microstructures and tensile properties of Ni3Al–Ni3V pseudo-binary alloys was investigated by a scanning electron microscope, a transmission electron microscope, Vickers hardness test, and high-temperature tensile test. As the alloy deviates from a just-stoichiometric composition toward Ni-rich one, the microstructures constituted by two ordered phases, Ni3Al and Ni3V changed to those constituted by two ordered phases, Ni3Al and Ni3V, and one disordered phase, Ni solid solution. Also, the deviation from the stoichiometric composition resulted in a decrease in flow strength as well as Vickers hardness and conversely increase in tensile elongation. Higher tensile elongation in the off-stoichiometric alloys was induced by the transition from intergranular fracturing to transgranular fracturing. The trade-off relation in the yield strength (or hardness) versus tensile elongation curve, which was drawn plotting the data obtained from the alloys with different off-stoichiometric compositions, was most excellent at 600 °C but rapidly became worse at high temperatures beyond 600 °C. It was demonstrated that the deviation to the off-stoichiometric composition in the two-phase Ni3Al–Ni3V pseudo-binary alloy system was a useful alloying parameter to improve the balance of the flow strength and tensile ductility.