Published online by Cambridge University Press: 15 July 2020

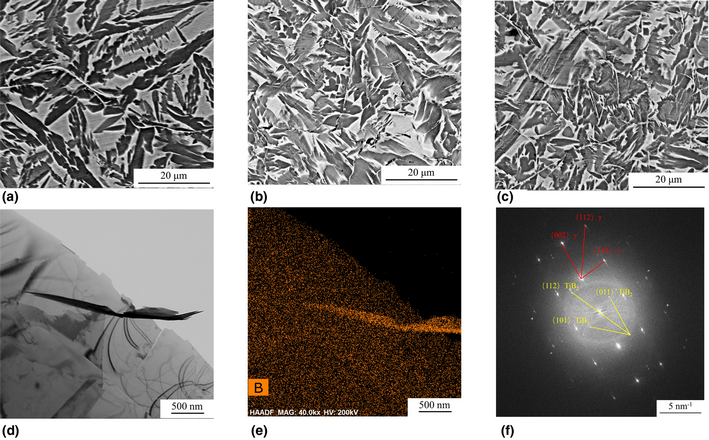

TiAl alloys are potential structural high-temperature structural materials at a service temperature of ~900 °C, while poor ductility at room temperature and high creep rate at the elevated temperature limits the applications. To improve the room-temperature and high-temperature mechanical properties of Ti–44Al–5Nb–3Cr–1.5Zr, Mo and B were introduced into this system and Ti–44Al–5Nb–3Cr–1.5Zr–xMo–yB alloys were proposed. And then, we, respectively, studied the microstructures and mechanical properties of Ti–44Al–5Nb–3Cr–1.5Zr–xMo–0B and Ti–44Al–5Nb–3Cr–1.5Zr–1Mo–yB to elucidate the role for the addition of Mo and B. It is found that Mo can increase the fraction of B2 phase in the alloys and the microstructures of the alloys are greatly refined by the addition of B. The compression test results indicate that Mo has a positive influence on the high-temperature compressive properties of TiAl-based alloys, whereas B addition can improve their room-temperature compressive properties of Ti–44Al–5Nb–3Cr–1.5Zr–1Mo–yB alloys; the morphology of borides in each sample should be the structural origin for these phenomena.