Article contents

Microstructure and thermophysical properties of CeO2-doped SmTaO4 ceramics for thermal barrier coatings

Published online by Cambridge University Press: 27 January 2020

Abstract

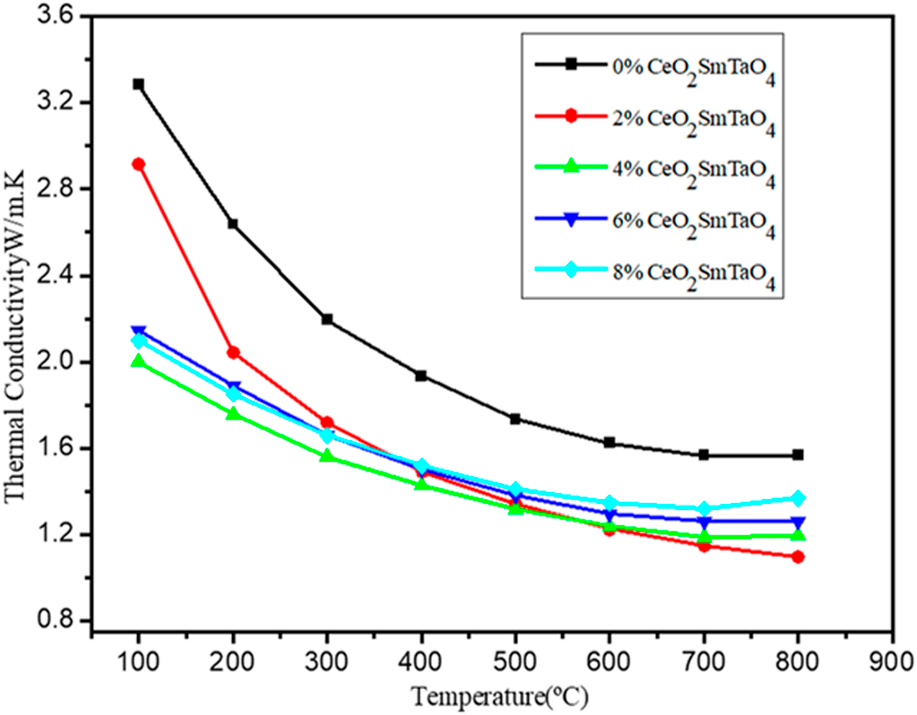

SmTaO4 ceramics have excellent high-temperature phase stabilities and mechanical properties and show great potential for use as next-generation thermal barrier coating (TBC) materials. CeO2–SmTaO4 ceramics are prepared via high-temperature solid–state reaction. It retains a single monoclinic phase structure. Ce4+ was reduced to Ce3+ by high-temperature deoxidation, and the Ce3+ ions substitute for an equal number of Sm3+ ions. The CeO2–SmTaO4 ceramics had lower thermal conductivities [1.09–2.75 W/(m K)] than yttria-stabilized zirconia (YSZ) [2.1–2.7 W/(m K)] at 100–800 °C, which decreased dramatically with increasing temperature. SmTaO4 doped with 2% CeO2 had lower thermal conductivity [1.09 W/(m K), 800 °C] than SmTaO4 [1.42 W/(m K), 800 °C] and 2% ZrO2-doped SmTaO4 ceramics [1.22 W/(m K), 800 °C]. The low thermal conductivity is attributed to Ce3+ substitution for an equal number of Sm3+ ions, and because Ce3+ ions are the strongest phonon scattering centers, they can decrease the phonon mean free path effectively. The thermal expansion coefficient of 8% CeO2–SmTaO4 ceramics is approximately 10.3 × 10−6 K−1 at 1200 °C, which is slightly higher than that of both YSZ (10.0 × 10−6 K−1) and SmTaO4 (9.58 × 10−6 K−1). The outstanding thermophysical properties indicate that CeO2–SmTaO4 ceramics are potential TBC materials.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2020

References

- 7

- Cited by