Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Wang, Xi-Shu

Tan, Chang-Hao

Ma, Juan

Zhu, Xiao-Dong

and

Wang, Qing-Yuan

2018.

Influence of Multi-Holes on Fatigue Behaviors of Cast Magnesium Alloys Based on In-Situ Scanning Electron Microscope Technology.

Materials,

Vol. 11,

Issue. 9,

p.

1700.

Subasi, Yasin

Turen, Yunus

Zengin, Huseyin

Ahlatci, Hayrettin

and

Sun, Yavuz

2019.

Effect of Zn addition on mechanical and corrosion properties of as-cast and as-extruded WE43 magnesium alloys.

Materials Research Express,

Vol. 6,

Issue. 11,

p.

1165f9.

Zhang, Xiaobo

Dai, Jianwei

Dong, Qiangsheng

Ba, Zhixin

and

Wu, Yujuan

2020.

Corrosion behavior and mechanical degradation of as‐extruded Mg–Gd–Zn–Zr alloys for orthopedic application.

Journal of Biomedical Materials Research Part B: Applied Biomaterials,

Vol. 108,

Issue. 3,

p.

698.

Wu, Guohua

Wang, Cunlong

Sun, Ming

and

Ding, Wenjiang

2021.

Recent developments and applications on high-performance cast magnesium rare-earth alloys.

Journal of Magnesium and Alloys,

Vol. 9,

Issue. 1,

p.

1.

Tong, Xin

Zhang, Guoqing

Wu, Guohua

Zhang, Liang

Wang, Yingxin

Jiang, Rui

Liu, Wencai

and

Ding, Wenjiang

2021.

Addressing the abnormal grain coarsening during post-weld heat treatment of TIG repair welded joint of sand-cast Mg-Y-RE-Zr alloy.

Materials Characterization,

Vol. 176,

Issue. ,

p.

111125.

Abedi, Hooman

Emamy, Massoud

Rassizadehghani, Jafar

and

Mirzadeh, Hamed

2022.

Synergistic Effects of Cerium-Based Rare Earth Addition and Hot Deformation on the Microstructure and Mechanical Properties of Mg-0.5Zn-0.5Zr Magnesium Alloy.

Metals and Materials International,

Vol. 28,

Issue. 5,

p.

1105.

Deng, Daiyi

Cheng, Renju

Dong, Zhihua

Jiang, Bin

Yang, Mingbo

Wang, Haijun

Yu, Chuntang

Ma, Yanlong

and

Pan, Fusheng

2023.

High strength and ductility of cast Mg-9Gd-1.5Y-0.8Zn-0.3Zr alloy achieved by microstructural regulation.

Progress in Natural Science: Materials International,

Vol. 33,

Issue. 6,

p.

797.

Lin, Jinming

Fu, Penghuai

Wang, Yingxin

Liu, Hong

Zheng, Ya

Peng, Liming

and

Ding, Wenjiang

2023.

Effect of La addition on microstructure, mechanical behavior, strengthening and toughening mechanisms of cast Mg-Gd-Zn alloy.

Materials Science and Engineering: A,

Vol. 866,

Issue. ,

p.

144688.

He, Fei-yu

Hu, Wen-xin

Liu, Li-juan

Ma, Shao-bo

and

He, Wei

2023.

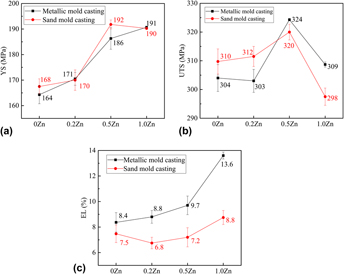

Effect of Zn addition on microstructure and mechanical properties of Mg-3Y-2Nd-0.5Zr alloy.

China Foundry,

Vol. 20,

Issue. 4,

p.

299.

Wang, Dan

He, Ying

Yu, Yangyang

Fan, Peng

Gao, Han

Fu, Penghuai

and

Peng, Liming

2023.

Microstructure and mechanical properties of cast Mg-6Gd–Zr alloy with different Y addition.

Journal of Materials Research and Technology,

Vol. 27,

Issue. ,

p.

4494.

Lin, Jinming

Fu, Penghuai

Wang, Yingxin

Ding, Yiwen

Liu, Hong

Peng, Liming

and

Ding, Wenjiang

2024.

Section dimension induced microstructure and mechanical properties variations of sequential solidified sand–cast Mg–10Gd–0.2La–0.1Zn–0.4Zr (wt%) alloy.

Materials Science and Engineering: A,

Vol. 897,

Issue. ,

p.

146359.

Yang, Lixiang

Shi, Hui

Huang, Yuanding

Wang, Kun

Dong, Xiwang

Wu, Hai

Lu, Chong

Gan, Weimin

Maawad, Emad

Sun, Baode

Li, Zhongquan

Hort, Norbert

and

Xiao, Lv

2024.

Achieving high mechanical performance of the large-scale sand-casting Mg–4Y–x nd–y Gd–0.4Zr alloys by tailoring Nd and Gd contents.

Materials Science and Engineering: A,

Vol. 900,

Issue. ,

p.

146476.