Article contents

The microstructure and mechanical properties of Al2024-SiCp composite fabricated by powder thixoforming

Published online by Cambridge University Press: 27 March 2017

Abstract

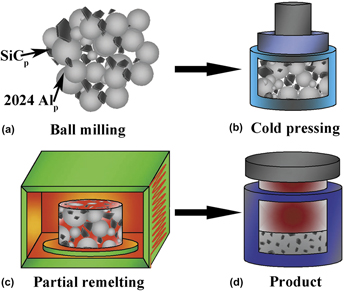

In this study, SiC particle reinforced Al2024 matrix composites were fabricated by powder thixoforming (PT). Meanwhile, 2024 alloys were fabricated by permanent mold cast (PMC) and PT, respectively, to reveal superiorities of PT technology over the traditional processing technologies and the resulting composite over the matrix alloy. The microstructures and mechanical properties of the three materials were comparatively investigated. The results indicated that both the PT materials possessed finer spheroidal primary particles and smaller eutectic concentration, but the PMC alloy comprised large equiaxed grains, continuously net-shaped eutectic structures, and many porosities. The mechanical properties of the PT alloy were significantly higher than those of the PMC alloy because of the enhanced compactness and work hardening, decreased eutectic concentration, and fine primary particles. The incorporation of SiCp to the PT alloy further brought improvements, the ultimate tensile strength (UTS), yield strength (YS), and hardness were increased by 29.3% (UTS = 388 MPa), 35% (YS = 297 MPa), and 46.8% (hardness = 122.6 HV), respectively. A strengthening model considering different strengthening mechanisms and SiCp failure was proposed and YS of composite could be exactly predicted.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 10

- Cited by