Article contents

Investigation on the multi-pass gas tungsten arc welded Bi-metallic combination between nickel-based superalloy and Ti-stabilized austenitic stainless steel

Published online by Cambridge University Press: 22 June 2017

Abstract

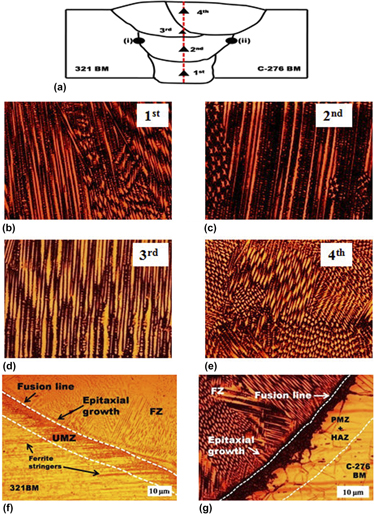

The present study addressed the weldability of Hastelloy C-276 and Type 321 austenitic stainless steel (ASS) dissimilar combination used for manufacturing of high-temperature equipments in nuclear power plants. Investigation of the microstructural evolutions across the different welding passes and their subsequent effect on the mechanical properties and corrosion resistance would be helpful in better understanding and pave way for the frequent application of such dissimilar joints in the industrial applications. The problem of segregation associated with the multi-pass gas tungsten arc welding process was also investigated systematically. The fusion zone microstructures exhibited a transition from columnar to an equiaxed dendritic structure with varying passes. The topologically closed packed (TCP) phases (such as P and μ) were observed in the fusion zone as well as at the weld interface of Hastelloy C-276. Polarization test was performed to evaluate the corrosion resistance and results indicated that the Cr and Mo depleted zones formed around the TCP phases might be responsible for decreased Epit value for fusion zone. The novelty of this work is to explore the possibilities of substitution of an expensive Hastelloy C-276 with a cost-effective Ti-stabilized Type 321 ASS.

Keywords

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 11

- Cited by