Article contents

Investigation of hydrogen embrittlement in 12Cr2Mo1R(H) steel

Published online by Cambridge University Press: 24 September 2018

Abstract

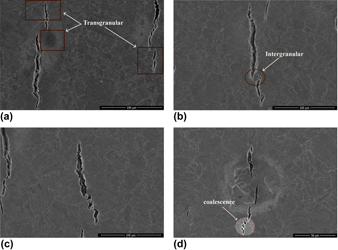

The hydrogen embrittlement of 12Cr2Mo1R(H) steel at different strain rates were investigated after hydrogen precharging for 4 h in a 0.5 M H2SO4 solution with 2 g/L ammonium thiocyanate. Results showed that the embrittlement index increased and gradually reached a relative stable value of about 20% at the strain rate of 5 × 10−5 s−1 with the decrease of strain rates. SEM images depicted small and deep flakes at high strain rates, while flakes grew larger at slow strain rates. Most hydrogen-induced cracks (HICs) were transgranular fracture through lath grain of bainitic ferrite. High strain field surrounds the crack tips, which makes the crack tips of two close and parallel cracks deflect toward each another and even form crack coalescence. The electron backscatter diffraction technique was used to investigate the effects of grain boundaries, recrystallization fraction, kernel average misorientation map, texture component, and coincidence site lattice boundaries on the HIC propagation. High densities of dislocations and strain concentrations were found around the cracks, where grains are highly sensitive to HIC.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 5

- Cited by