Article contents

Governing role of the ratio of large platelet particles to ultrafine particles on dynamic and quasistatic compressive response and damage evolution in ice-templated alumina ceramics

Published online by Cambridge University Press: 20 October 2020

Abstract

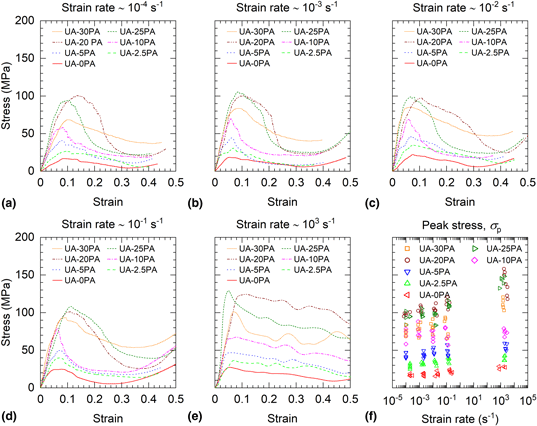

This study revealed that the mass ratio of large anisometric particles (platelets) to ultrafine, equiaxed particles strongly influences dynamic and quasistatic compressive response and the process of damage evolution in ice-templated alumina materials. The improved sinterability between particles of significantly dissimilar size and morphology enabled the utilization of a high mass ratio of the particles in harnessing a markedly enhanced level of strength in highly porous ice-templated ceramics. The high volume fraction of platelets increased lamellar bridge density and resulted in dendritic morphology as opposed to lamellar morphology without platelets. All the materials showed strain rate-sensitivity, where strength increased with strain rate. Materials with highly dendritic morphology exhibited the best performance in terms of maximum strength and energy absorption capacity, and the performance improved from quasistatic to dynamic regime. Direct observation of the process of damage evolution revealed the effects of both strain rate and ratio of platelets to ultrafine particles.

- Type

- Article

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 3

- Cited by