Article contents

Formation of micro-mechanical interlocking sites by nanoscale sculpturing for composites or hybrid materials with stainless steel

Published online by Cambridge University Press: 29 October 2020

Abstract

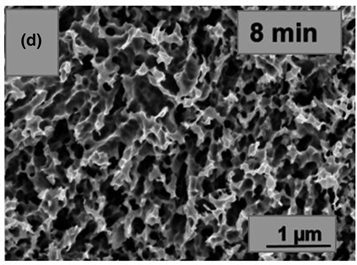

The demands of modern materials are highly challenging as well as partially contradictory. For example, materials should be strong like steels but chemically inert like soft low-surface energy polymers. These conflicts can be overcome by effectively combining disparate materials in composites that allow fusing of the traditional material classes like ceramics, polymers, and metals. Such combinations require sufficient adhesion between the individual materials. If adhesion is based on mechanical interlocking, the chemistry and chemical compatibility of the individual materials play a negligible role for the adhesion, but the mechanical properties of the materials are exclusively important. This work focusses on a technologically relevant example of a micro-mechanical interlocking surface structure on grade 304 stainless steel (SST) by nanoscale sculpturing. Using a low aggressive/low toxic seawater-like and diluted HNO3-based electrolyte, the resulting structure is free from preferential grain-boundary etching. The sculptured surface is super hydrophilic with undercuts suitable for mechanical interlocking with polymers. In single-lap shear tests, different two-component adhesives failed cohesively on structured SST while showing more than a doubling of the ultimate shear strength compared to the state-of-the-art grit-blasted SST composites which only showed adhesive failure.

Keywords

- Type

- Invited Feature Paper

- Information

- Copyright

- Copyright © The Author(s), 2020, published on behalf of Materials Research Society by Cambridge University Press

References

- 4

- Cited by