Article contents

A finite element study on the hardness of carbon nanotubes-doped diamond-like carbon film

Published online by Cambridge University Press: 11 November 2011

Abstract

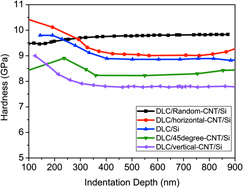

The hardness of the carbon nanotubes (CNTs)-doped diamond-like carbon (DLC) films is modeled by a nanoindentation finite element analysis. A three-dimensional (3D) formation where CNTs are modeled as transverse isotropy is compared with a two-dimensional (2D) analysis with isotropic CNTs. The results showed that for small CNTs volume fraction, the overall hardness of CNTs/DLC/Si composites is controlled by the elastic modulus along the indentation direction. For vertical CNTs-doped DLC films, the hardness in 3D analysis is close to that in 2D analysis if the isotropic elastic modulus is taken as the long-axis direction. However, for horizontal CNTs-doped DLC films, the hardness in 3D and in 2D is similar if the 2D isotropic elastic modulus is taken as the short-axis direction of the 3D elastic modulus. As a result, for small CNTs volume fraction, the hardness of CNTs/DLC/Si composites can be modeled by a 2D isotropic inclusion as long as the elastic modulus is chosen properly. The hardness in CNTs/DLC/Si composites depends on the orientation of CNTs and the volume fraction. The mechanisms in hardness enhancement for different CNT orientations are explained by shear stress and the effective projected area. The issues like interface strength and indentation size effect are also addressed in terms of CNT orientations.

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 1: Focus Issue: Instrumented Indentation , 14 January 2012 , pp. 330 - 338

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 6

- Cited by