Article contents

Fast smoothing on diamond surface by inductively coupled plasma reactive ion etching

Published online by Cambridge University Press: 09 December 2019

Abstract

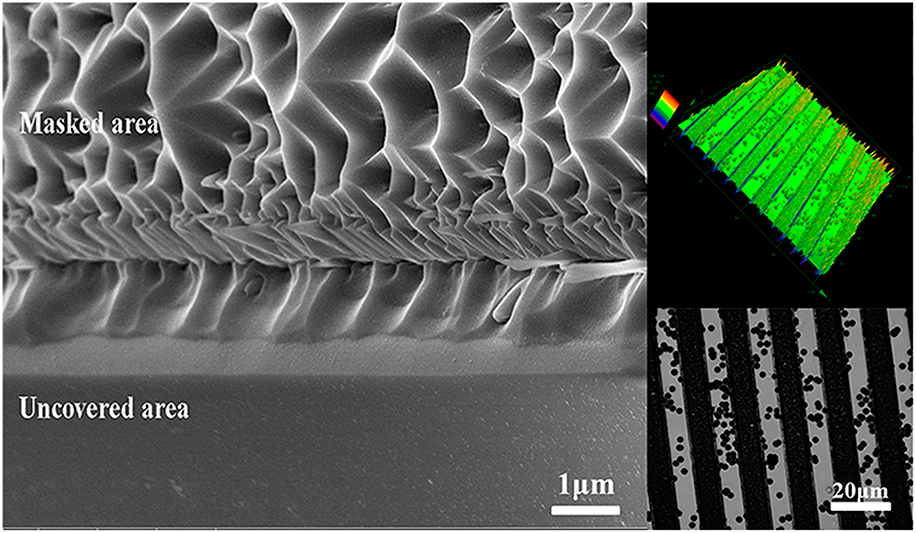

The synergetic effects of surface smoothing exhibited during the inductively coupled plasma reactive ion etching (ICP-RIE) of free-standing polycrystalline diamonds (PCDs) were investigated. Changing the assistive gas types generated variable surface oxidation states and chemical environments that resulted in different etching rates and surface morphologies. The main reaction bond mechanism (C–O) during ICP-RIE and the ratio of C–O–C/O–C=O associated with the existence of a uniform smooth surface with root mean square (RMS) roughness of 2.36 nm were observed. An optimal process for PCD smoothing at high etching rate (4.6 μm/min) was achieved as follows: 10% gas additions of CHF3 in O2 plasma at radio frequency power of 400 W. The further etched ultra-smooth surface with RMS roughness <0.5 nm at etching rate of 0.23 μm/min that being produced by transferring this optimum recipe on single crystal diamonds with surface patterns confirmed the effectiveness of the fast smoothing approach and its feasibility for diamond surface patterning.

Keywords

- Type

- Article

- Information

- Journal of Materials Research , Volume 35 , Issue 5: Focus Issue: The Science and Technology of Vapor Phase Processing and Modification of Surfaces , 16 March 2020 , pp. 462 - 472

- Copyright

- Copyright © Materials Research Society 2019

References

- 9

- Cited by