Article contents

Fabrication of large alumina foams by pyrolysis of thermo-foamed alumina–sucrose

Published online by Cambridge University Press: 12 January 2016

Abstract

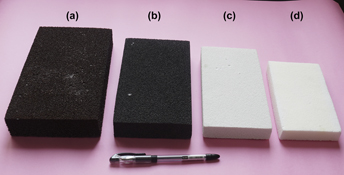

The aim of this study is to prevent cracks in large foam bodies prepared by thermo-foaming of alumina powder dispersions in molten sucrose. Cracks initiate in the binder burnout stage during which the bodies undergo shrinkage in the range of 32–49 vol% depending on sucrose content. Intermediate pyrolysis of the sucrose polymer binder prevents the cracking of large foam bodies as the carbon produced by pyrolysis binds the alumina particles during the initial stage of shrinkage and provides adequate strength to withstand the internal stresses produced during the pyrolysis and subsequent carbon burnout. The carbon bonded alumina foam bodies obtained after pyrolysis do not show any visible cracks during subsequent carbon burnout and sintering because the alumina particles establish a firm network with each other due to particle drag and rearrangement during pyrolysis of the sucrose polymer binder as evidenced from microstructure analysis. The carbon bonded alumina foam bodies show high compressive strength (2–1.3 MPa) and are amenable to machining operations such as milling and drilling without cracking.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 7

- Cited by