Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Glezer, A. M.

Muradimova, L. F.

Shirshikov, S. O.

Shchetinin, I. V.

D’yakonov, D. L.

and

Tomchuk, A. A.

2019.

Effect of Large Plastic Deformations in a Bridgman Chamber on the Structure and Properties of FeCo–V Alloys.

Bulletin of the Russian Academy of Sciences: Physics,

Vol. 83,

Issue. 10,

p.

1250.

Babuska, Tomas F.

Wilson, Mark A.

Johnson, Kyle L.

Whetten, Shaun R.

Curry, John F.

Rodelas, Jeffrey M.

Atkinson, Cooper

Lu, Ping

Chandross, Michael

Krick, Brandon A.

Michael, Joseph R.

Argibay, Nicolas

Susan, Donald F.

and

Kustas, Andrew B.

2019.

Achieving high strength and ductility in traditionally brittle soft magnetic intermetallics via additive manufacturing.

Acta Materialia,

Vol. 180,

Issue. ,

p.

149.

Kustas, Andrew B.

Fancher, Chris M.

Whetten, Shaun R.

Dagel, Daryl J.

Michael, Joseph R.

and

Susan, Donald F.

2019.

Controlling the extent of atomic ordering in intermetallic alloys through additive manufacturing.

Additive Manufacturing,

Vol. 28,

Issue. ,

p.

772.

Glezer, A.M.

Louzguine-Luzgin, D.V.

Muradimova, L.F.

Shirshikov, S.O.

Libman, M.A.

Shchetinin, I.V.

Perov, N.S.

Dyakonov, D.L.

and

Sundeev, R.V.

2019.

Observation of γ-phase suppression effect in soft-magnetic FeCo-(3–6) %V alloys under high pressure torsion.

Intermetallics,

Vol. 115,

Issue. ,

p.

106615.

Glezer, A M

Luzgin, D V

Muradimova, L F

Shirshikov, S O

Libman, M A

Schetinin, I V

Perov, N S

Dyakonov, D L

and

Sundeyev, R V

2020.

Structural phase changes during deformation of FeCo-V alloys by torsion under high pressure.

IOP Conference Series: Materials Science and Engineering,

Vol. 709,

Issue. 4,

p.

044091.

Yamazaki, Takahiro

Katabira, Kenichi

Narita, Fumio

Furuya, Yasubumi

and

Nakao, Wataru

2020.

Microstructure‐Enhanced Inverse Magnetostrictive Effect in Fe–Co Alloy Wires.

Advanced Engineering Materials,

Vol. 22,

Issue. 10,

Babuska, Tomas F.

Johnson, Kyle L.

Verdonik, Trevor

Subia, Samuel R.

Krick, Brandon A.

Susan, Donald F.

and

Kustas, Andrew B.

2020.

An additive manufacturing design approach to achieving high strength and ductility in traditionally brittle alloys via laser powder bed fusion.

Additive Manufacturing,

Vol. 34,

Issue. ,

p.

101187.

Susan, D. F.

Kustas, A. B.

Kellogg, R. A.

Carroll, J. D.

Michael, J. R.

and

Karaman, I.

2021.

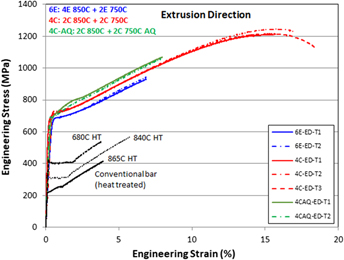

The Effects of Annealing After Equal Channel Angular Extrusion (ECAE) on Mechanical and Magnetic Properties of 49Fe-49Co-2V Alloy.

Metallurgical and Materials Transactions A,

Vol. 52,

Issue. 9,

p.

4090.

Ming, Kaisheng

Jiang, Shuimiao

Niu, Xiaoyuan

Li, Bo

Bi, Xiaofang

and

Zheng, Shijian

2021.

High-temperature strength-coercivity balance in a FeCo-based soft magnetic alloy via magnetic nanoprecipitates.

Journal of Materials Science & Technology,

Vol. 81,

Issue. ,

p.

36.

Glezer, A.M.

Muradimova, L.F.

Borisova, P.A.

Veligzhanin, A.A.

Chernysheva, O.V.

Sundeev, R.V.

Louzguine-Luzgin, D.V.

Perov, N.S.

Shirshikov, S.O.

and

Tomchuk, А.А.

2021.

EXAFS-spectroscopy and thermal neutron diffraction study of the effect of deformation by high pressure torsion on the atomic ordering and magnetic properties of the FeCo alloy.

Journal of Alloys and Compounds,

Vol. 866,

Issue. ,

p.

159021.

Kustas, Andrew B.

Susan, Donald F.

and

Monson, Todd

2022.

Emerging Opportunities in Manufacturing Bulk Soft-Magnetic Alloys for Energy Applications: A Review.

JOM,

Vol. 74,

Issue. 4,

p.

1306.

Kustas, Andrew B.

Mann, James B.

Trumble, Kevin P.

and

Chandrasekar, Srinivasan

2023.

Decoupling the effects of texture and composition on magnetic properties of Fe-Si sheet processed by shear deformation.

Journal of Magnetism and Magnetic Materials,

Vol. 568,

Issue. ,

p.

170349.

Adamczyk, Jesse Min-Tze

Barrick, Erin J.

Pearce, Charles J.

Delaney, Robert E.

Ury, Nicolas

Dillon, Robert Peter

Monson, Todd C.

Carroll, Jay D.

Susan, Donald F.

Valdez, Nichole R.

Lang, Eric

Hattar, Khalid

Love, Ana S.

Choi, Hyein

Kustas, Andrew B.

and

Firdosy, Samad A.

2024.

Functional Grading Between Soft-Magnetic Fe–Co/Fe–Ni Alloys and the Effect on Magnetic and Microstructural Properties.

ACS Applied Engineering Materials,

Vol. 2,

Issue. 4,

p.

818.