Article contents

Enhancing grain refinement efficiency and fading resistance of Al–B master alloys processed by equal channel angular pressing

Published online by Cambridge University Press: 23 April 2018

Abstract

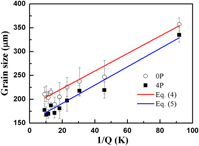

An Al–3% B master alloy has been subjected to equal channel angular pressing (ECAP). The grain refining performance and fading resistance of an Al–3% B master alloy on a commercial purity Al (CPA) have been evaluated. The effect of the number of ECAP passes on the size and the distribution of the AlB2 particles, the grain size of CPA ingots with and without adding the Al–3% B master alloy subjected to ECAP have been investigated. The mean size of AlB2 particles was significantly reduced from ∼34 to ∼12 μm after four ECAP passes. Fine blocky AlB2 particles were uniformly distributed in the Al matrix. It has been revealed that when it was inoculated by the Al–B master alloy subjected to ECAP, the grain size of α-Al was decreased from ∼1200 to ∼180 μm after four ECAP passes, beyond that, the grain size tends to be saturated. It has been proved that grain refinement efficiency and fading resistance of the Al–3% B master alloy subjected to ECAP in CPA ingots was enhanced.

- Type

- Article

- Information

- Copyright

- Copyright © Materials Research Society 2018

References

REFERENCES

- 2

- Cited by