Article contents

Engineering materials properties in codimension > 0

Published online by Cambridge University Press: 26 October 2011

Abstract

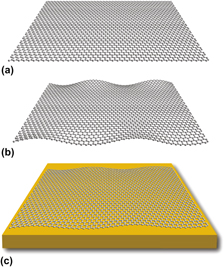

When thin nanomaterials spontaneously deform into nonflat geometries (e.g., nanorods into nanohelices, thin sheets into ruffled forms), their properties may change by orders of magnitude. We discuss this phenomenon in terms of a formal mathematical concept: codimension c = D − d, the difference between the dimensionality of space D, and that of the object d. We use several independent examples such as the edge stress of graphene nanoribbons, the elastic moduli of nanowires, and the thermal expansion of a modified bead-chain model to demonstrate how this framework can be used to generically understand some nanomaterial properties and how these properties can be engineered by using mechanical constraints to manipulate the codimension of the corresponding structure.

Keywords

- Type

- Articles

- Information

- Journal of Materials Research , Volume 27 , Issue 3: Focus Issue: Advances in Mechanics of One-Dimensional Micro/Nanomaterials , 14 February 2012 , pp. 619 - 626

- Copyright

- Copyright © Materials Research Society 2011

References

REFERENCES

- 1

- Cited by