Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Tan, Yuan-Yuan

Su, Ming-Yao

Niu, Yang-Yang

Xie, Zhou-Can

Chen, Zhong-Jun

Gong, Yu

Chen, Jin-Xi

Wu, Zhong-Hua

Wang, Hai-Ying

Liaw, Peter K.

and

Dai, Lan-Hong

2021.

Probing temperature effects on lattice distortion and oxidation resistance of high-entropy alloys by in situ SR-XRD and XANES.

Journal of Materials Research,

Vol. 36,

Issue. 21,

p.

4413.

Li, Na

Chen, Wentian

He, Junyang

Gu, Ji

Wang, Zhangwei

Li, Yue

and

Song, Min

2021.

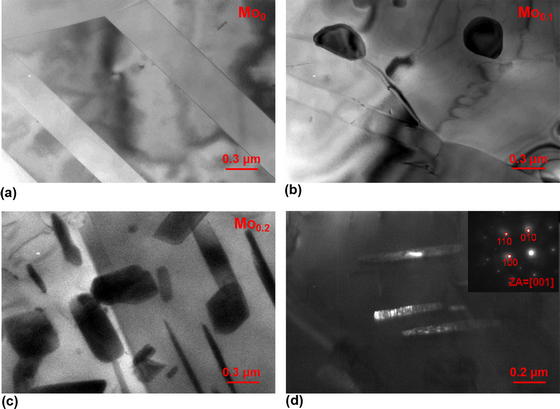

Dynamic deformation behavior and microstructure evolution of CoCrNiMox medium entropy alloys.

Materials Science and Engineering: A,

Vol. 827,

Issue. ,

p.

142048.

Jiang, Di

Cui, Hong-zhi

Song, Xiao-jie

Lian, Xiao-juan

Zhao, Xiao-feng

Chen, Hao

and

Ma, Guo-liang

2022.

Wear and corrosion resistance of CoCrNi composite coatings by laser cladding.

China Foundry,

Vol. 19,

Issue. 6,

p.

535.

Yang, Tao

Shu, Xiaoyong

Hu, Linli

Qiu, Panpan

Liu, Ri

and

Yuan, Si

2022.

Effects of Y Additions on the Microstructure and Mechanical Properties of Cocr1.7ni Medium Entropy Alloys.

SSRN Electronic Journal ,

Zhang, Hao

Tong, Yonggang

Cao, Shanhong

Hu, Yongle

Ji, XiXi

Tang, Quan

Yang, Lingwei

Zhang, Xiancheng

and

Hua, Manyu

2022.

Outstanding yield strength of CoCrNiTa0.1 medium entropy alloy under the synergistic regulated with nanoprecipitation and grain refining.

Journal of Alloys and Compounds,

Vol. 919,

Issue. ,

p.

165715.

Li, Na

He, Junyang

Zhou, Yuhao

Gu, Ji

Ni, Song

and

Song, Min

2022.

Strain rate effects on the mechanical responses in Mo-alloyed CoCrNi medium entropy alloys.

Materials Science and Engineering: A,

Vol. 856,

Issue. ,

p.

143944.

Nutor, Raymond Kwesi

Cao, Qingping

Wang, Xiaodong

Ding, Shaoqing

Zhang, Dongxian

and

Jiang, Jian-Zhong

2022.

Accelerated emergence of CoNi-based medium-entropy alloys with emphasis on their mechanical properties.

Current Opinion in Solid State and Materials Science,

Vol. 26,

Issue. 6,

p.

101032.

Chan, Shu-Ni

and

Hsueh, Chun-Hway

2022.

Effects of La addition on the microstructure and mechanical properties of CoCrNi medium entropy alloy.

Journal of Alloys and Compounds,

Vol. 894,

Issue. ,

p.

162401.

Zhang, Hao

Tong, Yonggang

Hu, Yongle

Tang, Quan

Ji, Xixi

Yang, Lingwei

Hua, Manyu

and

Zhang, Xiancheng

2022.

1.8 GPa Ultra-Strong CoCrNiMo <sub>0.2</sub> Medium Entropy Alloy with Strength and Ductility Trade Off Via Double Precipitations and High Density Twins.

SSRN Electronic Journal ,

Bajpai, Sakshi

MacDonald, Benjamin E.

Rupert, Timothy J.

Hahn, Horst

Lavernia, Enrique J.

and

Apelian, Diran

2022.

Recent progress in the CoCrNi alloy system.

Materialia,

Vol. 24,

Issue. ,

p.

101476.

Chang, Wei-Che

Lu, Ying-Chou

and

Hsueh, Chun-Hway

2022.

Oxide dispersion strengthening of CoCrNi medium entropy alloy using TiO2 particles.

Materials Science and Engineering: A,

Vol. 859,

Issue. ,

p.

144196.

Hong, Xinwei

and

Hsueh, Chun-Hway

2022.

Effects of yttrium addition on microstructures and mechanical properties of CoCrNi medium entropy alloy.

Intermetallics,

Vol. 140,

Issue. ,

p.

107405.

Xu, Hui

Xia, Yubing

Chen, Mengya

Ma, Le

Li, Haonan

Li, Bin

Wu, Zhongyuan

and

Tan, Xiaohua

2023.

Effect of Mo addition on AC soft magnetic property, hardness and microstructure of FeCoNiMo (0 ≤ x ≤ 0.25) medium entropy alloys.

Materials Characterization,

Vol. 206,

Issue. ,

p.

113435.

Jang, Tae Jin

Lee, You Na

Ikeda, Yuji

Körmann, Fritz

Baek, Ju-Hyun

Do, Hyeon-Seok

Choi, Yeon Taek

Gwon, Hojun

Suh, Jin-Yoo

Kim, Hyoung Seop

Lee, Byeong-Joo

Zargaran, Alireza

and

Sohn, Seok Su

2023.

Compositive role of refractory element Mo in improving strength and ductility of face-centered-cubic complex concentrated alloys.

Acta Materialia,

Vol. 255,

Issue. ,

p.

119030.

Chang, Wei-Che

and

Hsueh, Chun-Hway

2023.

Strengthening of CoCrNi medium entropy alloy with Ti additions.

Intermetallics,

Vol. 163,

Issue. ,

p.

108072.

Lin, Yvonne

Lu, Ying-Chou

Li, Chia-Lin

and

Hsueh, Chun-Hway

2023.

Modifying crystallinity and mechanical properties of (CoCrNi)95.8Ce4.2 medium entropy alloy films by post-annealing treatment.

Surface and Coatings Technology,

Vol. 456,

Issue. ,

p.

129265.

Deshmukh, Poonam S.

and

Sathiaraj, G Dan

2023.

Microstructure, mechanical properties, and strain rate sensitivity of vacuum arc melted CoCrNi medium entropy alloy.

Materials Today: Proceedings,

Zhang, Hao

Ren, Ziyi

Tong, Yonggang

Hu, Yongle

Ji, Xixi

Yang, Lingwei

Wang, Kaiming

Fang, Jingzhong

Chen, Hui

and

Liang, Xiubing

2023.

Introduction of nanotwins into nanoprecipitations strengthened CoCrNiMo0.2 alloy to achieve strength and ductility trade-off: A comparative research.

Journal of Materials Science & Technology,

Vol. 156,

Issue. ,

p.

172.

Yu, Zewen

and

Lin, Yaojun

2023.

Achieving High Strength and Good Ductility in a Nb-Containing CoCrNi-Based High-Entropy Alloy by Grain Boundary and Precipitates Strengthening.

Metals,

Vol. 13,

Issue. 5,

p.

936.

Wang, Yu

Sun, Chongfeng

Yang, Zhong

Li, Jianping

Bai, Yaping

Guo, Qiaoqin

and

Qian, Dan

2023.

Abnormal annealing-induced strengthening in Ni39.3Al15.7Fe45 eutectic medium entropy alloy.

Journal of Materials Research and Technology,

Vol. 27,

Issue. ,

p.

4765.