Article contents

The effects of flash allowance and upset allowance on microstructures and mechanical properties of flash butt welded RS590CL steel joints

Published online by Cambridge University Press: 14 November 2016

Abstract

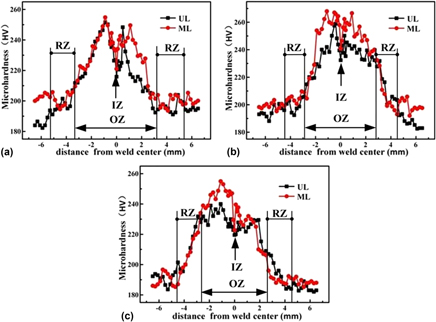

The flash allowance and upset allowance have significant effects on characteristics of flash butt welded RS590CL steel joints. The overheated zone (OZ) widths increased with flash allowance (δf) increase, and decreased as the upset allowance (δu) increased. The coarsened upper bainite was formed in interface zone (IZ) and OZ as δf increased. With increasing δu, the large plastic deformation occurred and the interface formability improved. The hardness in IZ was a little lower than that in its vicinity OZ due to some ferrite existence and dislocation amount decreased in IZ. The tensile strengths of flash butt welding (FBW) joints were in good match with base metal and the ductilities were lower. The maximum bending crack length was 0.68 mm which indicated that the bending properties of FBW joints were good. Under this experiment, relatively large δf (10–12 mm) and δu (5.5–6.5 mm) were recommended for the benefit of high quality FBW joints.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

References

REFERENCES

- 5

- Cited by