Crossref Citations

This article has been cited by the following publications. This list is generated based on data provided by

Crossref.

Ding, Chao

Shi, Hailong

Wu, Kun

Wang, Xiaojun

Gan, Weimin

Hu, Xiaoshi

and

Xu, Chao

2020.

Processing, microstructure and mechanical properties of a novel mg matrix composites reinforced with urchin-like CNTs@SiCp.

Diamond and Related Materials,

Vol. 109,

Issue. ,

p.

108087.

Zhang, Zhiming

Fan, Genlian

Tan, Zhanqiu

Zhao, Haitao

Xu, Yanjin

Xiong, Dingbang

and

Li, Zhiqiang

2021.

Bioinspired multiscale Al2O3-rGO/Al laminated composites with superior mechanical properties.

Composites Part B: Engineering,

Vol. 217,

Issue. ,

p.

108916.

Zhang, Zhiming

Fan, Genlian

Tan, Zhanqiu

Zhao, Haitao

Xu, Yanjin

Xiong, Dingbang

and

Li, Zhiqiang

2021.

Towards the strength-ductility synergy of Al2O3/Al composite through the design of roughened interface.

Composites Part B: Engineering,

Vol. 224,

Issue. ,

p.

109251.

Gao, Mian

Shen, Zhitao

Yue, Gentian

Dong, Chen

Wu, Jihuai

Gao, Yueyue

and

Tan, Furui

2022.

Synergistic Effects of In4sns8@Mos2@Cnts on Electrode Interface Catalysis and Charge Transfer in Efficient Dye-Sensitized Solar Cells.

SSRN Electronic Journal ,

Van Trinh, Pham

Lee, Junho

Kang, Byungchul

Minh, Phan Ngoc

Phuong, Doan Dinh

and

Hong, Soon Hyung

2022.

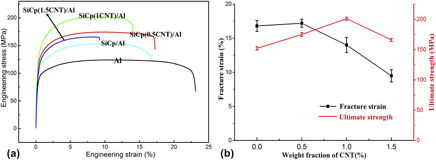

Mechanical and wear properties of SiCp/CNT/Al6061 hybrid metal matrix composites.

Diamond and Related Materials,

Vol. 124,

Issue. ,

p.

108952.

Wang, Xiaoshu

Su, Yishi

Qiu, Caihao

Zhu, Chengnan

Wang, Xiaozhen

Cao, He

Zhang, Di

and

Ouyang, Qiubao

2022.

Mechanical behavior and interfacial micro-zones of SiCp(CNT) hybrid reinforced aluminum matrix composites.

Materials Characterization,

Vol. 189,

Issue. ,

p.

111982.

He, Ye

Shen, Zhitao

Yue, Gentian

Gao, Yueyue

Huo, Jinghao

Dong, Chen

Mao, Yangfan

and

Tan, Furui

2022.

A dye-sensitized solar cells with enhanced efficiency based on a “pillared effect” of CoMoP2 @Mxene@CNTs composite counter electrode.

Journal of Alloys and Compounds,

Vol. 922,

Issue. ,

p.

166279.

Tu, Sisi

Wang, Qun

and

Ramachandran, Chidambaram Seshadri

2022.

Parametric investigation of in-situ synthesis of carbon nanotubes on Al2O3 powder by the rotary chemical vapor deposition method.

Ceramics International,

Vol. 48,

Issue. 19,

p.

28258.

Gao, Mian

Shen, Zhitao

Yue, Gentian

Dong, Chen

Wu, Jihuai

Gao, Yueyue

and

Tan, Furui

2023.

One-pot hydrothermal in situ growth of In4SnS8@MoS2@CNTs as efficient Pt-free counter electrodes for dye-sensitized solar cells.

Journal of Alloys and Compounds,

Vol. 932,

Issue. ,

p.

167643.

Ravoor, Jishita

Selvam, Renold Elsen

Karuppan, Deepan

and

Puthillam, Umanath

2023.

Development of robocasted MWCNTS-calcium silicate 3D structures for bone regeneration applications with retention of MWCNTS using vacuum sintering technique.

Journal of Materials Research,

Vol. 38,

Issue. 9,

p.

2389.

Peng, Yahui

Zhao, Haitao

Ye, Jinrui

Yuan, Mingqing

Tian, Li

Li, Zhiqiang

Liu, Yang

and

Chen, Ji'an

2023.

3D multiscale tri-level finite element analysis of aluminum matrix composites with Nano&Micro hybrid inclusions.

Composite Structures,

Vol. 305,

Issue. ,

p.

116545.

Yue, Youcheng

Zhou, Lei

Li, Mengnie

Xu, Fushun

and

Cai, Xiaolan

2023.

Research Progress on Microstructure Design of CNTs Reinforced Al Matrix Composites.

Integrated Ferroelectrics,

Vol. 234,

Issue. 1,

p.

22.

Wei, Lin

Liu, GuiLi

Qian, ShaoRan

Zhao, JingWei

Jiao, Gan

and

Zhang, GuoYing

2024.

Molecular dynamics study of the mechanical properties of hydrated calcium silicate enhanced by functionalized carbon nanotubes.

Journal of Molecular Modeling,

Vol. 30,

Issue. 2,

CHEN, Yu-yao

NIE, Jin-feng

FAN, Yong

GU, Lei

XIE, Ke-wei

LIU, Xiang-fa

and

ZHAO, Yong-hao

2024.

Enhancing strength–ductility synergy of AlNp/Al composite by regulating heterostructure of matrix grain and particle distribution.

Transactions of Nonferrous Metals Society of China,

Vol. 34,

Issue. 4,

p.

1049.

Divakar, Sanoj

Sardar, Santanu

Sah, Satesh

and

Das, Debdulal

2025.

A state-of-the-art review on SiC and MWCNTs reinforced hybrid metal matrix composites: Processing, properties, and applications.

Hybrid Advances,

Vol. 10,

Issue. ,

p.

100454.