Article contents

Effects of Ag variations on dynamic recrystallization, texture, and mechanical properties of ultrafine-grained Mg–3Al–1Zn alloys

Published online by Cambridge University Press: 03 October 2016

Abstract

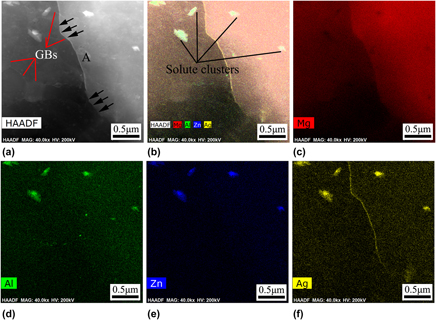

In this study, the effects of Ag variations on dynamic recrystallization (DRX), texture, and mechanical properties of ultrafine-grained Mg–3Al–1Zn alloys are investigated. The results suggest that Ag segregation and Al–Zn–Ag clusters form in the Mg matrix with Ag addition less than 1 wt%, which retard DRX and the growth of the DRXed grains. The resulting grain size decreases from 513 to 316 nm. As the Ag addition increases to 2 wt%, the Mg54Ag17 phase precipitates along the grain boundary, which plays an important role in restricting DRXed grain growth via grain boundary pinning effect. The resulting grain size is 375 nm with a bimodal grain size distribution. The extrusion texture of the investigated alloys is in fairly scattered orientation distribution. The weak basal texture and ultrafine grain size lead to the high yield asymmetry ratio. The Ag-containing extruded alloys exhibit an increase in the tensile and compressive properties. The strengthening mechanisms due to grain refinement, dislocations, solid solution, precipitates, solute clusters, and segregation are discussed.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2016

Footnotes

Contributing Editor: Jürgen Eckert

References

REFERENCES

- 11

- Cited by