Article contents

Effect of twisting fatigue on the electrical reliability of a metal interconnect on a flexible substrate

Published online by Cambridge University Press: 04 December 2017

Abstract

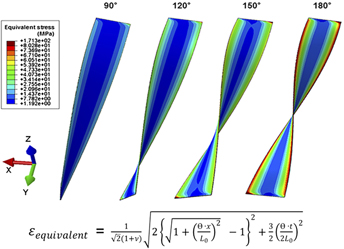

To secure the reliability of flexible electronics, the effect of multicomponent stress on the device properties during complex mechanical deformation needs to be thoroughly understood. The electrical resistances of metal interconnects are investigated by in situ monitoring at different twisting angles and with different pattern positions. As the twisting angle increased, the electrical resistance increased earlier. Furthermore, in the line pattern located far from the central axis, severe electrical degradation and fatigue damage formation were observed. Multicomponent stress evolution during twisting was analyzed by the finite-element simulation method. For easy practical application for estimating the representative twisting strain, an analytic solution of twisting deformation was formulated and compared with the simulation. Using the equivalent strain, the fatigue lifetime was fitted, and the exponents were obtained for lifetime expectation. This systematic study provides the guidelines for highly reliable flexible devices and the tools for determining the expected fatigue lifetime.

- Type

- Articles

- Information

- Copyright

- Copyright © Materials Research Society 2017

Footnotes

Contributing Editor: C. Robert Kao

References

REFERENCES

- 10

- Cited by